eddy current clutch brake

eddy current clutch brake

eddy current clutch brake

eddy current clutch brake

eddy current clutch brake

eddy current clutch brake

eddy current clutch brake

eddy current clutch brake

eddy current clutch brake

eddy current clutch brake

eddy current clutch brake

eddy current clutch brake

eddy current clutch brake

eddy current clutch brake

eddy current clutch brake

eddy current clutch brake

eddy current clutch brake

eddy current clutch brake

eddy current clutch brake

eddy current clutch brake

eddy current clutch brake

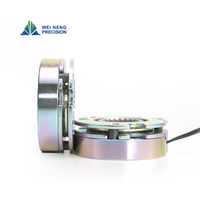

Eddy Current Clutch Brake: An Introduction

The eddy current clutch brake is an advanced braking mechanism that utilizes the principles of electromagnetic induction to provide efficient and controllable stopping power. This innovative technology is widely employed in various industrial applications, offering not only high performance but also reliability and safety. With its unique design, the eddy current clutch brake provides an effective solution for managing motion control in machinery.

Types of Eddy Current Clutch Brakes

Understanding the different types of eddy current clutch brakes can help in selecting the right one for your needs. Here are the common types available:

- Standard Eddy Current Clutch Brakes: These are designed for general applications, offering a balance between performance and cost-effectiveness.

- High-Power Eddy Current Brakes: Ideal for heavy-duty applications, providing superior braking efficiency and thermal stability.

- Compact Eddy Current Clutches: These are smaller in size, making them suitable for space-constrained environments while still delivering reliable performance.

- Custom Eddy Current Solutions: Tailored designs that meet specific operational requirements, ensuring compatibility with unique machinery configurations.

Applications of Eddy Current Clutch Brakes

Eddy current clutch brakes find their applications across a diverse range of industries. Understanding where they can be effectively utilized is crucial for engineers and maintenance professionals:

- Automotive Industries: Used in hybrid vehicles for regenerative braking systems.

- Manufacturing: Commonly applied in conveyor systems and automated production lines for smooth stopping.

- Metallurgy: Utilized in the testing and handling of metal strips and sheets, ensuring precision in operations.

- Aerospace: Employed in landing gear systems to enhance braking capabilities during landings.

- Mining Equipment: Essential for controlling large machinery and ensuring safe operation in harsh environments.

Advantages of Eddy Current Clutch Brakes

The adoption of eddy current clutch brakes offers several significant advantages, making them a preferred choice in many applications:

- Durability: With fewer moving parts compared to traditional brakes, eddy current clutch brakes experience less wear and tear, resulting in a longer lifespan.

- High Efficiency: They provide smooth engagement and disengagement with minimal energy loss, thus improving overall system efficiency.

- Low Maintenance: The closed design minimizes dust and debris accumulation, reducing maintenance efforts and costs.

- Instant Response: These brakes offer rapid braking by harnessing electromagnetic forces, allowing for immediate control of machinery movement.

- Noise Reduction: The operation of eddy current brakes is quieter than standard mechanical brakes, making them ideal for sensitive environments.