electric wheel hub motor

electric wheel hub motor

electric wheel hub motor

electric wheel hub motor

electric wheel hub motor

electric wheel hub motor

electric wheel hub motor

electric wheel hub motor

electric wheel hub motor

electric wheel hub motor

electric wheel hub motor

electric wheel hub motor

electric wheel hub motor

electric wheel hub motor

electric wheel hub motor

electric wheel hub motor

electric wheel hub motor

electric wheel hub motor

electric wheel hub motor

electric wheel hub motor

electric wheel hub motor

Types of Electric Wheel Hub Motors

Electric wheel hub motors hub motor bicycle are typically classified into four types:

- Direct drive hub motors: Direct drive hub motors are electric motors that power the wheels of a vehicle. They are located in the wheel hub itself and eliminate the need for traditional drivetrain components, such as axles and gearboxes. Direct drive motors offer instant torque, smooth acceleration, and high efficiency. Because they are integrated into the wheel hub, they also free up space within the vehicle for additional cargo or passenger space. These motors do not require complex gear systems, which reduces maintenance needs and potential points of failure. Direct drive hub motors can be used in electric vehicles and electric bicycles.

- Geared hub motors: Geared hub motors are electric motors used in various applications, such as electric bicycles, electric scooters, and electric vehicles. These motors are integrated into the hub of the wheel and use a gear system to increase torque and efficiency. Geared hub motors typically provide better hill-climbing ability and acceleration at lower speeds than direct-drive hub motors, making them popular for applications requiring higher torque at startup. The gear system also allows for a more compact design, which can be advantageous in applications with limited space. Additionally, geared hub motors can offer better efficiency at lower speeds, resulting in improved battery life and overall range for electric vehicles.

- AC hub motors: AC hub motors are electric motors used in various applications, such as electric bicycles, electric scooters, and electric vehicles. These motors are integrated into the hub of the wheel and use alternating current (AC) to operate. They are known for their smooth and quiet operation, as well as their high efficiency and low maintenance requirements. AC hub motors typically provide good performance at high speeds, making them suitable for applications requiring high-speed operation and extended range. These motors also offer regenerative braking capability, which allows energy to be recaptured and stored in the battery during braking, improving overall efficiency and range. Additionally, AC hub motors can be designed to be lightweight and compact, making them ideal for applications with limited space and weight constraints.

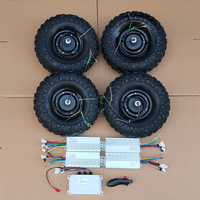

- AWD hub motors: All Wheel Drive (AWD) hub motors are electric motors that provide power to all four wheels of a vehicle, distributing torque to each wheel independently through hub motors integrated into the wheels. This system enhances traction, stability, and handling, especially in adverse weather conditions or off-road terrain. AWD hub motors can also improve efficiency, as each wheel can be driven independently based on the specific needs of the terrain and driving conditions. Additionally, they offer the advantage of eliminating traditional drivetrain components, such as axles and differentials, which can reduce weight and increase space efficiency within the vehicle. These motors are commonly used in electric vehicles, e-bikes, and e-scooters, providing enhanced performance and versatility.

Scenarios of Electric Wheel Hub Motors 6

Electric wheel hub motors have a wide range of applications across various transportation and mobility sectors. Here are some key application scenarios:

- Bicycles and E-Bikes: Hub motors are common in electric bicycles and e-bikes, providing pedal-assist and throttle capabilities. They enhance the riding experience by offering additional power for hill climbing, acceleration, and overcoming resistance, making e-bikes popular for commuting, recreational riding, and urban transport.

- Electric Scooters and Skateboards: Hub motors power electric scooters and skateboards, providing propulsion and enabling high-speed travel. They are particularly sought after for their quiet operation and low maintenance needs, benefiting both personal and shared mobility solutions.

- Electric Trikes and Quadricycles: Hub motors are used in electric trikes and quadricycles to provide stable and efficient transportation alternatives for individuals with mobility challenges and those seeking eco-friendly urban transport solutions.

- In-Wheel Motors for Cars: Some electric vehicles (EVs) use hub motors as in-wheel motors, eliminating the need for complex drivetrains. This application enhances space efficiency, reduces weight, and improves handling and traction control in EVs.

- Goods and Cargo Transport: Hub motors power electric scooters and skateboards, providing propulsion and enabling high-speed travel. They are particularly sought after for their quiet operation and low maintenance needs, benefiting both personal and shared mobility solutions.

- Personal Mobility Devices: Hub motors are used in electric wheelchairs and mobility scooters, providing reliable and efficient mobility solutions for individuals with disabilities and those with limited mobility.

- Recreational Vehicles: ATVs, UTVs, and other recreational vehicles sometimes use hub motors for electric variants, offering off-road capabilities and environmentally friendly alternatives for outdoor adventures.

- Public Transport Solutions: Hub motors are integrated into electric buses and shuttles, providing quiet, zero-emission public transport alternatives for urban and suburban areas, reducing traffic noise and greenhouse gas emissions.

- Last-Mile Delivery Solutions: Hub motors power electric scooters and bikes for last-mile delivery services, offering efficient and flexible delivery solutions that navigate through traffic congestion and reduce carbon footprints.

- Industrial Applications: Hub motors are used in some industrial applications, such as automated guided vehicles (AGVs) and material handling equipment, providing efficient and maintenance-free drive solutions in warehouses and factories.

How to choose electric wheel hub motors

When looking for an electric wheel hub motor, one should consider the application, the motor type, power output, wheel size, and compatibility.

The application for which the hub motor is needed is a crucial factor. Different hub motors are suitable for different applications. For instance, if one is looking for a motor for a dense urban area, a motor with low power output that can achieve high acceleration and a compact design will be ideal. On the other hand, if one is looking for a motor for rough terrain, a motor that can generate high torque and has a higher power output will be more suitable.

Both the type of hub motor and the application it is used for will affect how the vehicle is powered. The two main types of hub motors are geared and gearless hub motors. Geared hub motors use internal gears, while gearless hub motors use a direct drive. Geared hub motors produce high torque at low speeds, making them suitable for hilly areas and starting off from a standstill position. Gearless hub motors are more efficient and produce more power, making them suitable for high-speed driving.

Power output is an important factor when choosing a hub motor. The power output will determine the rate of acceleration, the ability to climb steep hills, and how well the motor performs in different conditions. For instance, a motor with low power output will struggle to climb up hills and accelerate from a standstill position.

Another important factor is the size of the wheel. The larger the wheel, the more area it will cover and the better it will perform off-road. However, larger wheels also mean more weight, which can affect acceleration and climbing ability. It is important to find the right balance between wheel size and motor power output for the intended application.

It is also important to consider the compatibility of the hub motor with other components of the vehicle, such as the battery, controller, and drivetrain. The hub motor must be compatible with these components to function properly.

Function, Feature, and Design of Electric Wheel Hub Motors

Functions

Electric wheel hub motors have functions that make them essential in the sports industry. They are energy-efficient, which helps conserve energy while delivering the necessary power. The motors are designed for easy installation, providing convenience and accessibility during the installation process. They also offer quiet operation, which provides a serene environment during sports activities. Electric wheel hub motors are also built for durability, which ensures they last long and perform well in different conditions.

Features

- Power Output: The power output of electric wheel hub motors varies depending on their intended use. For instance, electric bike hub motors typically range from 250W to 1000W, with 500W being common for electric bikes and 1000W for electric motorcycles. Electric cars may have hub motors ranging from 50kW to over 300kW, with higher power outputs for performance and luxury vehicles.

- Torque: Torque is crucial for the performance of hub motors, especially for vehicles requiring quick acceleration and climbing ability. Electric bike hub motors offer torque between 30Nm to 80Nm, while electric car hub motors provide significantly higher torque, often exceeding 1000Nm, depending on the vehicle's specifications.

- Efficiency: Efficiency is vital for all hub motors to minimize energy loss and maximize range. Electric bike hub motors have an efficiency rate of around 80-90%, meaning 80-90% of the energy from the battery is converted to motion. Electric car hub motors also aim for high efficiency, typically around 90% or more, to ensure optimal performance and battery life.

- Integration: Hub motors are designed to integrate seamlessly with the vehicle's overall system. Electric bike hub motors are built into the wheels, replacing traditional bicycle hubs. Electric car hub motors are integrated into the wheel assemblies, connecting with the vehicle's electrical system and wheel components.

- Maintenance: Hub motors require minimal maintenance compared to traditional motors. They are sealed units, protecting them from dust and water, which is crucial for outdoor and off-road use. Periodic checks for battery health and general wear are typically the only maintenance requirements.

Design

- Electric bike hub motors: These motors are lightweight and compact, which makes them suitable for bikes. They can be installed in different areas, like the front or rear wheel, ensuring the center of gravity is maintained. The motor's casing is made from aluminum or magnesium alloy, which protects the internal components and reduces overall weight. The design also includes a waterproof sealing system to prevent water and dust from entering the motor, which can cause damage.

- Electric car hub motors: Electric car hub motors are heavier than electric bike hub motors because cars require more power and torque. They are integrated into the wheel assembly, with the motor placed in the center of the wheel. The casing is made from durable materials such as aluminum or magnesium alloy, protecting the internal components from external damage. The motors are also designed with waterproof seals to prevent water and dust damage.

Q & A

Q: What is an electric wheel hub motor?

A: An electric wheel hub motor is a motor found in the wheel of a vehicle. The wheel hub motor is responsible for providing drive torque to the vehicle. Electric wheel hub motors are used in electric vehicles, e-bikes, and e-scooters. They come in three main types: geared hub motors, gearless hub motors, and axial flux hub motors.

Q: What does a hub motor do?

A: A hub motor provides torque to propel a vehicle. The motor's power output and torque determine how well the vehicle can perform in different terrains and inclines.

Q: What is the difference between a hub motor and a regular motor?

A: The main difference between a hub motor and a regular motor is where it is located. Hub motors are located in the wheel, while regular motors are located in the vehicle's chassis.

Q: What are the advantages of hub motors?

A: Hub motors have several advantages. They are easier to install and require less maintenance since they have fewer moving parts. They are also quieter than regular motors and provide a smoother ride.

Q: What are the disadvantages of hub motors?

A: Hub motors have limited thermal management and can overheat during strenuous use. They also have limited torque and can struggle with steep hills and off-road terrain. In the case of in-wheel hub motors, they also affect the vehicle's unsprung mass, which can affect handling.