electrolytic copper cathodes

electrolytic copper cathodes

electrolytic copper cathodes

electrolytic copper cathodes

electrolytic copper cathodes

electrolytic copper cathodes

electrolytic copper cathodes

electrolytic copper cathodes

electrolytic copper cathodes

electrolytic copper cathodes

electrolytic copper cathodes

electrolytic copper cathodes

electrolytic copper cathodes

electrolytic copper cathodes

electrolytic copper cathodes

electrolytic copper cathodes

electrolytic copper cathodes

electrolytic copper cathodes

electrolytic copper cathodes

electrolytic copper cathodes

electrolytic copper cathodes

Types of Electrolytic Copper Cathodes

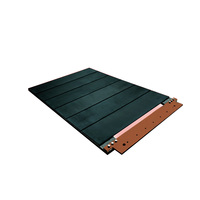

In copper production, the refining process forms electrolytic copper cathodes, which are pure copper sheets used widely in electrical and industrial applications. Different types can be identified based on purity standards, production methods, dimensions, and specific industrial applications.

-

Standard Grade Cathodes

The most common type, these cathodes, follows the CU-ETP standard set by the International Copper Study Group or ICSG>. They have 99.99% copper content with high conductivity and malleability. Basic oxygen furnaces and flash smelting nac copper concentrate electrolyte for copper cathodes.

-

High Grade Copper Cathodes

High-grade cathodes have slightly stricter purity requirements, often exceeding the standard grade. They are used in sensitive aerospace and electronics industries where even minor impurities can affect product performance. Electrolytic copper cathodes are produced from fine copper ore through a process called electrolysis.

-

Ultrapure Copper Cathodes

Ultrapure cathodes are developed for high-tech industries like semiconductors and renewable energy. With purities above 99.999%, these cathodes assure that critical components function with unmatched reliability. ICSG and American National Standards Institute (ANSI) usually set the standards for ultrapure copper cathodes.

-

Custom Shaped Cathodes

Electrolytic copper cathodes for specific industrial needs are often shaped into custom sizes or forms. These may include rods, plates, or specialized designs for unique manufacturing processes. This cathode type targets niche industries and applications requiring non-standard dimensions.

-

Continuous Cast Cathodes

They differ from electrolytic cathodes as they are produced using a continuous casting process rather than electrolysis. They still offer high purity but are generally less expensive and more readily available. Continuous cast cathodes find extensive applications in construction and general manufacturing.

Industries

-

Electrical Industry

The high conductivity of electrolytic copper makes it a core material in the electrical industry. They are integral components in wiring systems, electric motors and generators, power transmission lines, and circuit boards. Their 99.99% purity ensures efficient energy transfer, greatly reducing heat losses.

-

Construction and Architecture

Because of its resistance to corrosion, copper is a staple material in plumbing and roofing solutions. In construction, cathodes get melted down to produce copper pipes, sheets, and other architectural components. The long life span and recyclability feature of copper support sustainability objectives within the construction sector.

-

Transportation Industry

Transportation systems like power lines, motors, and components utilize copper cathodes. These cathodes enhance efficiency and reliability in automotive electrical systems as well as aeronautical and maritime applications. Copper's lightweight and strong features improve energy efficiency in modern transport solutions.

-

Telecommunications and Electronics

Telecommunication and electronic systems that include circuit boards, connectors, and transistors use cathodes. High-grade and ultrapure cathodes are critical to ensuring signal integrity, data transmission, and the overall performance of electronic devices. Thus, cathodes are vital in this industry as an increasing number of gadgets rely on copper for their functionality.

-

Renewable Energy Sector

They also find applications in solar panels and wind turbine components in the renewable energy sector. Copper’s high conductivity enhances the efficiency of energy harvesting and transmission systems. The recyclable nature of copper aligns with eco-friendly values of this sector.

-

Industrial Manufacturing

Coppers' versatility has seen its application across industries like machinery, automotive parts, and heat exchangers. With good thermal conductivity and resistance to corrosion, copper-centered items guarantee durability and efficiency in various industrial settings. Furthermore, custom-shaped cathodes cater to specific production needs to enhance operational efficiency.

Advantages

-

Unmatched Purity

The cathodes contain 99.99% copper making them some of the purest copper sources available. This purity guarantees high conductivity, which reduces power losses in various applications. This purity level assures that electrolytic copper cathodes are essential in critical applications where even minor impurities can affect performance.

-

Superior Conductivity

Copper is the most effective metal in conducting electricity after silver. This is because 99.99% of the copper in electrolytic cathodes makes them ideal for electrical applications. High conductivity reduces energy losses and improves operational efficiency in power transmission systems, electric motors, and wiring.

-

Longevity and Durability

Corrosion resistance is a key feature that enables copper to last in harsh environmental conditions. This contributes to longer life spans for systems and components built with cathodes. In construction and electrical systems, cathode-enhanced copper guarantees reliability and lower maintenance costs over time.

-

Sustainability and Recyclability

When it is no longer needed, cathodes can be recycled multiple times without losing their purity, making copper one of the most sustainable materials. Recycling contributes to reduced environmental impact, resource conservation, and cost-effectiveness. Various industries can thus align their operations with sustainability goals through the use of copper.

-

Highly Versatile

Electrolytic copper cathodes find applications that range from electrical to construction and transportation, thus proving their versatility. This adaptability makes them fundamental materials across such a wide range of industries as telecommunications, renewable energy, and even industrial manufacturing. Custom-shaped cathodes cater to niche needs further extending their usability.

-

Improved Heat Management

Copper has exceptional heat dissipation abilities. This makes it ideal for applications in which temperature control is essential, like electronic devices and power systems. Its proficiency in spreading heat eliminates overheating potential, therefore enhancing user safety and device longevity.

How to Choose

When looking for copper cathodes, buyers should consider several factors to ensure that they get the ones that will work for them.

-

Purity level

Bearing in mind what they will use the cathodes for will help buyers decide the purity level they need. Those intending to use them for electronics or aerospace will have to settle for ultra-pure copper cathodes since they are meant for sensitive applications. If for general use, high-grade or standard-grade cathodes will work just fine.

-

Electrolytic copper cathode sheet size

Cathode sheet size will also affect the usage. Buyers that require cathodes for industrial use should source large sheets while those that need them for small production unit use can get small sheets. Buyers may also get custom shape sheets to suit specific needs.

-

Supplier reputation

Buyers should get electrolytic copper from reputable suppliers to ensure that they get high-quality products. They can research the supplier online, check reviews, and ask for recommendations from other copper cathode users in their networks. They can also check the supplier's business verification status on the platform.

-

Stocking and storage capabilities

Buyers should consider the suppliers' capacity to hold stock. They should also consider the logistics and storage of the cathodes they order. By ordering cathodes that are in stock, they can ensure timely deliveries. After ordering, buyers should also ensure that they have suitable storage for the cathodes to prevent damages before they are transported to work sites.

-

Pricing

Buyers should compare prices from different suppliers and choose the one that has the cheapest price for the type and grade of copper cathodes they require. However, they should also ensure that they settle for a supplier that offers them bulk purchase discounts. Since copper prices fluctuate, they should also consider getting copper futures to cushion their businesses in case the prices drop.

Q & A

Q1: What is an electrolytic copper cathode?

A1: An electrolytic copper cathode is a refined copper sheet obtained by electrolysis, with a minimum purity of 99.99%. Copper cathodes are the primary raw material used in the production of copper products.

Q2: What are the qualities of good copper cathodes?

A2: Good copper cathodes should have a purity of 99.99%. They should also have a uniform thickness of not more than 1 millimeter. Additionally, they should have smooth and shiny surfaces and should be devoid of any scratches, dents, or marks.

Q3: What are the uses of copper cathodes?

A3: Copper cathodes are further processed to make copper wires, copper sheets, and copper pipes, among other products. They are also used in metallurgy to make alloys and in electronics to make circuit boards.

Q4: What should buyers consider when choosing a copper cathode supplier?

A4: When choosing a copper cathode supplier, buyers should consider the supplier's reputation. They should also consider the type and grade of copper cathodes the supplier has, the pricing, and the suppliers' capability to deliver bulk orders consistently.