food grade belt conveyor

food grade belt conveyor

food grade belt conveyor

food grade belt conveyor

food grade belt conveyor

food grade belt conveyor

food grade belt conveyor

food grade belt conveyor

food grade belt conveyor

Inclined Easy-to-clean IP66 Waterproof Food Grade PU Belt Conveyor for Food Industry Focus Machinery

food grade belt conveyor

food grade belt conveyor

food grade belt conveyor

food grade belt conveyor

food grade belt conveyor

food grade belt conveyor

food grade belt conveyor

food grade belt conveyor

food grade belt conveyor

food grade belt conveyor

food grade belt conveyor

Types of food-grade belt conveyors

Belt conveyors for processing materials have different uses in food service. These types differ in how they move food through different processing stages.

Here are some common types:

Modular Belt Conveyor

Modular belt conveyors use small plastic or metal pieces to form the belt. These pieces can easily be replaced or reconfigured. This modular system is highly versatile for different food processing needs. The resilience of these belts makes them suited for tasks demanding longer service life.

Gravity Conveyor

Food-grade gravity conveyors transport items using their natural weight. Inclined setups allow products to slide down without power. Rollers, sleighs, or wheels featuring belts aid this process. Gravity options are cheap and energy-efficient for simple movement tasks and don't require electricity to function.

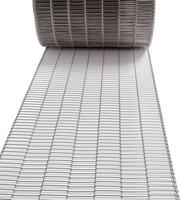

Steel Belt Conveyor

Steel belt conveyors for food processing involve belts made from steel plates or strips. These belts are strong and support abnormal or sharp-edged items. Steel belts work well in harsh situations with temperature variations or heavy loads. They are resilient and ideal for tough circumstances.

Swivel Belt Conveyor

Swivel belt conveyors hold one or more conveyor sections that can rotate. This ability helps change the direction of transported items. The swivel parts improve the processing area layouts as the users change item flow routing. This adaptability suits work areas with frequent layout changes.

Cleated Belt Conveyor

Cleated belt conveyors have raised sections, or cleats, on the surface. These cleats keep food products from slipping on steep inclines. The cleat arrangement depends on the product size and movement angle. Cleated belts handle bulk foods, liquids, or items prone to sliding. They maintain stability and minimize product spillage.

Industrial applications of food-grade belt conveyors

Transportation and distribution

Food-grade belt conveyors transport bulk food products from one place to the other. These conveyors have been used to move raw materials into processing machines and the finished items into packaging. Belt conveyors cut down the need for manual hauling and improved production efficiency.

Waste Management

Waste Management Belt conveyors transport discarded items like organic leftovers, peels, and the parts that cannot be used during processing. Taking these wastes away for disposal or recycling helps initiate a new cycle of production.

Packaging

Food-grade belt conveyors move food placed in boxes or cans to be packed. The conveyor moves items to where workers can pack them or to machines that automatically pack them. This speeds up the packaging process while making it better.

Assembly and Inspection

In industries where food safety is most important, the conveyor belt with washdown capability is used for assembling and checking foods. The conveyors are used to move processed foods to where they are checked for quality. Workers or machines can then examine the items for size, appearance, or safety. This helps ensure only good items are sent out.

Distribution and logistics

Conveyor belts are used in warehouse and distribution center systems to move food boxes and pallets. The belts save time by transporting items for storage or delivery. Automated conveyors move items faster than doing it by hand. They assist warehouses in operating quicker and managing inventory well.

Storage and Inventory Management

Conveyor belts move large food boxes or pallets to storage areas like warehouses. They're used in vertical storage systems that stack items. Belt conveyors help warehouses control stock by transporting items to the right spot. Moving foods smoothly keeps storage areas organized and makes it simple to find items.

Assembly and Packaging

Food-grade belt conveyors move items during packaging. They transport bulk foods like grains, liquids, or fragile items such as fruits to have the items packaged using some machines. The conveyor moves the food to be packed without spilling or damaging it. Keeping items steady avoids losses and makes packing quicker to help sales.

Product specifications and features of food-grade belt conveyors

Key features

- Food-grade materials: The parts of the food belt conveyor are made from materials that are safe and easy to clean. These materials are strong and last long, even when cleaned often or used for many years.

- Washdown capability: The conveyors can handle water and detergents due to IP ratings. This helps remove all food traces and germs.

- Maintenance-friendly: The belt type conveyor is simple to fix or change parts. Many use tools and parts that are easy to find. Proper attention makes them last longer with little downtime.

- Stability: Different widths and cleat arrangements help stabilize various food items during transport. Smooth movement prevents spills or pile-ups.

- Energy efficiency: Many newer models for food use have low energy needs. Smart motor systems and pulley designs consume less power to help lower operational costs.

How to install

- First, prepare a base or frame for the belt conveyor. The frame supports the conveyor parts and keeps everything aligned.

- Install the pulleys by attaching them to the frame. The motor pulley should have a motor connected to drive the belt.

- Attach the belt to the pulleys. Ensure the belt is properly fitted for smooth operation.

- Fix the tension system, usually a pulley or screw, on one pulley side to keep the belt tight and in proper shape.

- Do the electrical wiring next. Connect the motor to the switch and power source for easy operation.

- Finally, test the belt conveyor. Turn it on, then check for any problems with the belt or parts before putting it to use.

How to use

- Users should first turn on the motor to start moving the conveyor belt. This gives the pulley the power to rotate the belt.

- The speed controller adjusts the movement rate. Users should set the ideal speed for the product and conveyor type.

- Users should ensure the belt was clean before placing any item to be carried. This prevents contamination.

- Users should place items evenly on the belt so it does not tip or become imbalanced. This ensures smooth transport.

- A final check is done to see that safety shields are on and the emergency switch is ready. Now the conveyor can be used safely.

Maintenance and repair

- Daily washing of the conveyor belt prevents food build-up and germs from contaminating the belt.

- Weekly oiling of important moving parts like rollers ensures smooth operation and prevents rust from forming.

- Checking the belt weekly helps find problems like small tears or wear. Fixing them right away keeps the work running.

- Tightening loose screws and bolts prevent parts from shaking during use. It is good to check and tighten them every few weeks.

- Changing the motor's oil and other fluids as recommended by the maker keeps the motor working well for many years.

- Checking and possibly changing filters, as the maker advises, keeps dust and dirt from affecting performance.

Quality and safety considerations of food-grade belt conveyors

Check material safety

The parts of food conveyors should be made from materials that are safe for food contact, like stainless steel or special plastic. These materials should not break down or mix with the food. Users should always pick conveyors with parts made from materials that are easy to clean.

Cleanliness

Cleaning the conveyor often prevents germs and food residue from building up, which can cause spoilage. An infrequent cleaning schedule can lead to residue build-up that attracts pests or fosters germs, which causes food contamination. Users should ensure the belt is clean before each use and have a routine washing plan.

Germs on conveyor belts

Germs found on unclean conveyor belts affect the quality of foods being transported. Users should wash belts before transporting new food items to stop this from happening. There should also be a washdown capability on the conveyor.

Employ proper lubrication

Lubrication makes some parts slippery, reducing friction and wear as they move against each other. It keeps the machine running smoothly while increasing the lifespan of the parts. All lubricants must be safe for food processing, especially for belts used to move food directly. Users must ensure the lubricants won't hurt food. The right care keeps the belt conveyor running well.

Germs on unclean conveyor belts

Germs found on unclean conveyor belts affect the quality of foods being transported. Users should wash belts before transporting new food items to stop this from happening. There should also be a washdown capability on the conveyor.

Employ proper lubrication

Lubrication makes some parts slippery, reducing friction and wear as they move against each other. It keeps the machine running smoothly while increasing the lifespan of the parts. All lubricants must be safe for food processing, especially for belts used to move food directly. Users must ensure the lubricants won't hurt food. The right care keeps the belt conveyor running well.

Consistent maintenance helps detect problems early

Regularly checking the conveyor prevents accidents or failures while moving food. Inspections find small problems before they cause harm or slow down work. When issues arise, they can be fixed quickly without much downtime. Buyers should frequently track the conveyor's health to keep it safe and working well.

Q&A

Q1: What is the role of a food-grade belt conveyor in food safety?

A1: It helps with food safety by moving food in a clean and safe way. The materials used to make the conveyor are safe for food contact, like special plastics or metals. The conveyor can be washed easily to remove germs. It also keeps food from touching dangerous surfaces. These features stop food from getting contaminated and ensure that food stays in a healthier state.

Q2: How do food-grade belt conveyors handle diverse food products?

A2: It can carry many foods because the type of belt can be picked to match how safely the product will be carried. Cleated belts hold loose or bulk foods in place. Fragile items like fruits stay whole with restrictive belts. Custom-designed belts handle special tasks by adjusting to the demands of different kinds of foods.

Q3: What is the lifespan of a food-grade belt conveyor?

A3: How long the conveyor lasts depends on how often it is used, what kind of food it carries, and how well it is cleaned. With the right attention like regular cleaning and changing worn parts, some conveyors can last more than ten years of steady use in food plants. Proper maintenance helps the conveyor last longer while doing its job safely.

Q4: What are the key differences between a food-grade conveyor and a regular conveyor?

A4: Supporters of food-grade conveyors use better parts that do not let food be harmed. They make it easy to wash away germs and stop rust from happening. They are made to move delicate things without breaking them, which is not always true for general-use conveyors. They guarantee food safety with special rules and checks that other conveyors do not have.

Q5: Which industries benefit most from using food-grade belt conveyors?

A5: The food and drink, farming, and meat and fish processing industries all use these conveyors. People in packaging and baking also use them. Anywhere that moves food or raw materials needs special conveyors. These conveyors make sure food stays clean and safe as it moves from one spot to another.