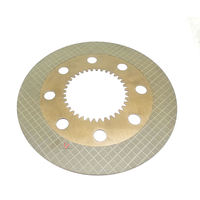

friction plate

friction plate

friction plate

friction plate

friction plate

friction plate

friction plate

friction plate

friction plate

friction plate

friction plate

friction plate

friction plate

friction plate

friction plate

friction plate

friction plate

friction plate

friction plate

friction plate

Types of Friction Plate

A friction plate is a component in machinery and vehicles that uses friction to transmit power or slow down and stop motion. Friction plates are used in brake and clutch systems. A friction plate is also called a friction disk or friction surface. There are two main types of friction plates.

- Friction plates in brakes: Brakes are divided into drum brakes and disc brakes. In drum brakes, the friction plate is called a friction drum. It is a cylindrical metal housing that rotates with the wheel. The inside surface of the friction plate rubs against the brake shoes to slow down the vehicle when one presses the brake pedal. A friction plate in a disc brake is a rotor. It is a flat metal disc attached to the wheel hub. When one presses the brake pedal, the caliper slides and pushes the brake pads against the rotor. The friction between the pads and the rotor slows down the vehicle. The friction plates in brakes are made of steel, cast iron, or composite materials that provide durability and consistent friction performance.

- Friction plates in clutches: Clutches also have two types of friction plates. The first one is the clutch disc, a flat round plate sandwiched between the flywheel and pressure plate. The friction surface of the clutch disc engages with the flywheel to transmit power from the engine to the wheels. The friction surface against the flywheel is called the friction lining. The material used is high-carbon steel, friction composites, or organic materials that provide good wear resistance and friction stability. The lining is bonded or riveted to the clutch disc. The rivets provide a mechanical attachment that ensures the lining stays on the disc even under high torque loads. The bonding and rivet work together to ensure the clutch disc functions reliably and efficiently in transmitting engine power to the wheels.

Specification & Maintenance of Friction Plates

There are several specifications to consider when purchasing friction plates, including size, material, application, and brand. Below are the specifications of friction plates:

-

Size

Friction plates are available in different sizes, which are measured in width and diameter. The size of a friction plate to be purchased will depend on the specific requirements of a vehicle or machinery.

-

Material

Friction plates are made with different materials, such as steel, cast iron, copper, and composite materials. Each of these materials has its own advantages and disadvantages. The plates made with composite materials tend to offer better performance. This is because they are able to withstand high levels of friction and wear.

-

Application

Friction plates can be used in different applications, such as automotive and industrial machinery. Depending on the application, the performance and specifications of a friction plate may vary.

-

Brand

Just like any other vehicle part, friction plates are available in different brands. It is important to purchase a plate from a reputable brand. This is because reputable brands offer high-quality plates that are durable and reliable.

It is important to maintain friction plates in order to avoid wear and tear, which can lead to replacement of expensive parts like the clutch and brakes. Here are some maintenance tips:

-

Regular Inspection

The first step to maintaining the friction plate is to regularly inspect it. This helps the user to identify any signs of damage or wear before they become serious. During inspection, it is important to look out for cracks, chip and discoloration.

-

Proper Lubrication

Friction plates require proper lubrication for them to work well. This is because the right level of lubricant reduces wear and tear, ensuring that the plates last longer. It is important to use the right lubricant, as recommended by the manufacturer.

-

Cleanliness

Keeping the friction plates clean is important for maintaining them. This is because dust, debris and dirt can cause damage or wear to the plates. It is advisable to clean the plates regularly and ensure that they are free from contaminants.

-

Use Quality Components

Using quality components when installing a friction plate is important. This is because quality components ensure that the plate functions effectively. When purchasing components, be sure to purchase them from reputable manufacturers.

-

Follow Manufacturer Instructions

When installing or maintaining a friction plate, it is important to follow the manufacturer's instructions. This is because the manufacturer's instructions provide valuable information on how to maintain and install the plate successfully.

How to Choose Friction Plate

Friction plates are not one-size-fits-all components. Here are some key factors to consider when choosing a friction plate for a specific application:

-

Application:

In choosing a friction plate, first consider the application it will be used for. Is it for a heavy-duty truck, sports car, or daily commuter vehicle? Different applications have different demands in terms of durability, heat dissipation, and engagement characteristics.

-

Material:

Friction plates are made from different materials, each suitable for different applications. Plates made from organic materials such as resin and fibers are well suited for friction plates in normal driving conditions. For high-performance vehicles, metallic plates offer better durability and heat resistance.

-

Size and Compatibility:

Ensure the friction plate is the right size and compatible with the rest of the clutch system. For instance, it should match the diameter and tooth count of the flywheel and be designed to work with the pressure plate and clutch disc.

-

Performance vs. Longevity:

There is a trade-off between performance and longevity. High-performance vehicles may require plates that offer quick engagement and disengagement, while commercial vehicles may prioritize durability and a smooth power transfer.

-

Budget:

Organic plates are more affordable, but they don't last long compared to metallic and ceramic plates. Hence, when choosing a friction plate, consider the budget but also consider the long-term cost implications in terms of maintenance and replacement.

How to DIY and Replace Friction Plate

Here is a simple guide on how to replace friction plates.

- 1. Gather the necessary tools: To replace friction plates, users need basic hand tools such as a socket wrench set, screwdrivers, and pliers. They may also require specialty tools like a torque wrench or clutch alignment tool, depending on the vehicle's make and model.

- 2. Ensure safety: Before starting any work on the vehicle, it is essential to prioritize safety. Park the car on a flat surface, engage the parking brake, and chock the wheels to prevent unintended movement. Disconnecting the vehicle's battery may also be necessary to avoid electrical issues.

- 3. Access the friction plates: Depending on the vehicle, users may need to remove components such as the driveshaft or transmission oil pan to reach the friction plates. Follow the manufacturer's instructions and use the appropriate tools to disassemble these parts safely.

- 4. Remove the old plates: Once the friction plates are accessible, take note of their arrangement and positioning. Use the socket wrench or other necessary tools to remove the fasteners securing the plates and carefully pull them off. Be cautious not to damage surrounding components during this process.

- 5. Clean the surface: Take advantage of the plate's accessibility to clean the area. Use a suitable cleaner to remove any dust, debris, or old lubricant from the transmission or axle housing where the friction plates sit. This ensures optimal performance and longevity for the new plates.

- 6. Install the new plates: Take the new friction plates out of their packaging and inspect them for any damage. Align the replacement plates according to the arrangement noted earlier and gently push them into place. Secure them with the appropriate fasteners, ensuring the right torque specifications are met.

- 7. Reassemble the components: Reattach any removed parts, such as the driveshaft or transmission oil pan, in the reverse order of disassembly. Ensure all gaskets, seals, and O-rings are replaced if necessary to prevent leaks. Follow the manufacturer's torque specifications for fastening bolts and nuts.

- 8. Check fluid levels: Before starting the vehicle, check the transmission or axle fluid levels. Top up the fluid if necessary, using the recommended type and quantity. This step is crucial after removing and reinstalling components that hold or circulate the fluid.

- 9. Test the vehicle: Start the car and let it idle for a few moments. Engage the gears and pay attention to any unusual noises or behaviors. Take the vehicle for a short test drive, ensuring the friction plates function correctly. Monitor the performance and inspect for leaks or abnormalities.

Q and A

Q1: How often should a friction plate be replaced?

A1: There is no specific period for replacing friction plates. It depends on the condition and level of wear. However, for normal driving, it is advisable to check the plate after 20,000 to 30,000 miles. Replace it as soon as possible to avoid further damage in case of heavy wear.

Q2: What causes friction plates to wear out faster?

A2: Friction plates can wear out quickly due to several factors. Driving habits such as frequent clutch riding, overloading the vehicle, and aggressive acceleration or braking can contribute to fast wear. Inadequate lubrication and poor quality plates also cause rapid damage.

Q3: What are the signs of a worn-out friction plate?

A3: The first signs of a worn-out friction plate are slipping of the clutch, difficulty in engaging gears, and noise when using the clutch. Visual inspection is also an effective way to detect wear.

Q4: Can a friction plate be repaired?

A4: Unfortunately, damage to the friction plate is beyond repair. The only solution is to replace it. This is because worn-out plates can cause more damage to the gearbox if not replaced in good time.

Q5: Are all friction plates compatible with every vehicle?

A5: No, friction plates are not compatible with all vehicles. Manufacturers produce different sizes and types suitable for specific vehicles. It is important to always choose a friction plate that matches the specifications of the vehicle in order to function effectively.