ground terminal

ground terminal

ground terminal

ground terminal

ground terminal

ground terminal

ground terminal

ground terminal

ground terminal

ground terminal

ground terminal

ground terminal

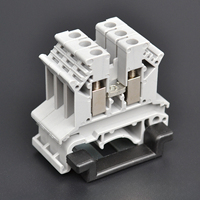

3 Pin Push Button Earthing Wire Connector Fireproof PP Plastic Quick Connection Ground Wire Terminal

ground terminal

ground terminal

ground terminal

ground terminal

ground terminal

ground terminal

ground terminal

ground terminal

Types of ground terminal

Ground terminals are available in diverse forms and configurations. Even though they perform the same basic function of grounding to enhance safety, performance, and reliability, each type is ideal for a particular application. The types include:

Ring Terminals

Often used in heavy electrical connections, ring terminal grounds provide a secure and stable connection. This terminal is designed to be bolted directly to a grounding point, ensuring a strong, vibration-resistant bond. This makes them suitable for industrial machinery, automotive systems, and marine applications.

Fork Terminals

Similar to ring terminals in terms of functionality, fork terminals allow an easy connection to a screw or a bolt, which provides a socket for a grounding lug rather than a solid base to mount an item. This terminal facilitates a connection’s easy disconnection and reconnection, making it ideal for equipment that sometimes needs frequent maintenance.

Bare Terminal

This type of grounding wire or terminal has no insulation and is typically used in high-voltage applications. They’re manufactured from pure copper, which is a good heat and electrical conductivity. Buyers prefer grounded terminal equipment for electrical insulation, corrosion resistance, and excellent conductivity.

Stud Mount Ground Terminal

Often used in panel or rack mount configurations, these terminals are designed to provide a grounding point for multiple wires or equipment. Comprised of threaded studs, they allow several ground connections to be made at a single point. This makes the stud mount terminals in power distribution systems, data centers, and industrial control panels.

Insulated Ground Terminal

Insulated ground terminals are designed to prevent accidental grounding, which could cause short circuits or equipment failure. Their insulated coating allows them to be electrically grounded yet protected from unintended contact. This makes them ideal for high-voltage electrical systems in manufacturing plants, power stations, and commercial buildings.

Material & Durability of ground terminal

The durability and material of the grounded terminal products are critical since they directly affect the performance, reliability, and application suitability. Consider the following materials:

Copper

Copper is the most common material for ground terminals due to its high electrical conductivity and corrosion resistance. Copper terminals are very durable, and they can withstand temperature fluctuations and environmental conditions. This makes them ideal for outdoor applications in construction sites, telecommunications, and electrical utilities.

Copper-Clad Aluminum (CCA)

The ground terminals offer a good balance between electrical conductivity and lightweight structure. Often used in construction and telecommunications, copper-clad terminals monitor where weight and efficiency properties are critical and where grounding connections must be robust and effective.

Stainless Steel

Manufacturers produce stainless steel terminals for adverse environments due to their exceptional durability and resistance to rust and corrosion. This terminal is particularly useful in marine, coastal, and outdoor installations. Stainless steel terminals have slightly lower electrical conductivity, which drops long-term resilience greatly.

Zinc-Plated Steel

Steel terminals are cost-effective and very strong, making them suitable for industrial applications. The zinc plating enhances corrosion resistance, which provides adequate protection in moderate-risk environments. These terminals are commonly used in manufacturing facilities, warehouses, and heavy machinery, where grounding must be very strong to resist mechanical wear.

Nickel-Plated Brass

Brass terminals offer excellent conductivity, while nickel plating provides additional protection against corrosion. This terminal type is ideal for high-performance applications where grounding must be reliable over extended periods. These terminals are mainly used in aerospace, military applications, and other high-tech environments.

Commercial value & Application of ground terminal

Ground terminals have critical applications across multiple industries that enhance electrical safety, system stability, and operational efficiency. The main commercial values include:

Industrial Machinery

Ground terminals in industrial machinery decrease the risk of electrical shocks and equipment damage. They improve operational safety and minimize downtime due to electrical faults, which directly impacts productivity in manufacturing plants and industrial facilities.

Data Centers

In data centers, grounding terminals protect sensitive computer hardware from power surges and static electricity. This grounding is essential for protecting servers and network equipment, which ensures system reliability and avoids costly equipment failures. The critical nature of their operation makes businesses rely on grounding systems daily to protect their operations.

Residential and Commercial Buildings

In residential and commercial construction, ground terminals are integral to electrical wiring systems. They ensure the safety of building occupants and avoid damage to electrical appliances and systems. As such, increased construction activity drives up the demand for grounding equipment in new builds, which leads to an increase in building codes and regulations.

Telecommunications

Grounding terminals provide crucial protection for telecommunications equipment against lightning strikes and power surges. They maintain system reliability in the telecom sector, ensuring uninterrupted service for many users. It’s critical for business continuity across various sectors, such as finance, healthcare, and logistics, to have reliable communication systems.

Transportation and Aerospace

Grounding terminals in the automotive, aerospace, and shipping industries are used to ensure the safety and reliability of electrical systems in vehicles, aircraft, and marine vessels. They help reduce the risks of electrical failures and enhance the safety of automated systems, which are very important in these industries for safety and regulations compliance.

How To Choose ground terminal

The key considerations when choosing the ground terminals include the following:

Safety Standards and Regulations Compliance

In various industries, grounding equipment is subject to strict safety regulations. Knowing the applicable regulations in the target market and ensuring there ground terminals align with the standards is vital for compliance and safety. IEC, OSHA and local electrical codes are examples of these regulations.

Fitout and Installation Considerations

The grounding terminals to a space must consider the available space and the systems in place. for instance, if mounting space is limited, then compact terminals are required. Also, some terminals require specific mounting arrangements, such as ring terminals, which need racks. It’s necessary to consider how the terminal will fit into the existing space and system, as this will affect the installation’s efficiency.

Environmental Factors

These factors directly influence the terminal’s longevity and performance, so one should consider them. For instance, if ever terminals are exposed to moisture, chemicals, or extreme temperatures, corrosion-resistant materials like stainless steel or CCA should be used. If they’re located in outdoor environments, consider terminals with UV protection to ensure reliable performance throughout.

Load Capacity and Electrial Requirements

The grounding terminals should support the maximum electrical load of the grounded equipment to ensure safety and avoid overloads. Understand the electrical requirements of the system and the load capacity of the terminal and check its wire gauge compatibility. Choosing the right terminal helps maintain system integrity and prevent electrical hazards.

Multi-Industry Usage

Ground terminals are critical in industries as they offer a critical grounding connection for the electrical system. They ensure safety from electrical shock and fire, protect equipment from power surges, and ensure the smooth operation of critical systems. The industries include construction, manufacturing, data centers, telecommunications, transportation, and energy.

Q&A

Q1: What are ground terminals used for?

ground terminals provide a safe pathway for excess electrical energy to travel into the ground. They protect people and equipment from electrical shock, power surges, and lightning strikes.

Q2: What factors impact the durability of grounding terminals?

The main factors that impact the durability of ground terminals include that exposure, stress, materials, thermal cycling, electrical wear, and environmental conditions.

Q3: How can one improve the durability of ground terminals?

One can improve the durability of grounding terminals by regularly inspecting them and using corrosion-resistant materials, such as copper or stainless steel. Further, proper installation of terminals reduces mechanical stress on cables and reduces thermal cycles.

Q4: Are grounding terminals in electrical systems necessary for all environments?

Ground terminals are critical and essential in both electrical systems and all environments. Their material ensures safe operation by providing overvoltage paths and electrical stability for system reliability.

Q5: Are terminals for grounding customized for specific applications?

Yes, terminals for grounding are customized based on specific application requirements. The applications include environmental conditions, electrical loads, space constraints, and industry standards to determine the appropriate grounding terminal.