heat shield fabric

heat shield fabric

heat shield fabric

heat shield fabric

heat shield fabric

heat shield fabric

heat shield fabric

heat shield fabric

heat shield fabric

heat shield fabric

heat shield fabric

heat shield fabric

heat shield fabric

heat shield fabric

heat shield fabric

heat shield fabric

heat shield fabric

heat shield fabric

heat shield fabric

heat shield fabric

heat shield fabric

Types of heat shield fabric

Heat shield fabric acts as a barrier to heat. It reflects and dissipates heat away from the source. It is used in various applications, such as automotive, aerospace, industrial, and motorcycle industries. Different types of heat shield fabrics are listed below:

-

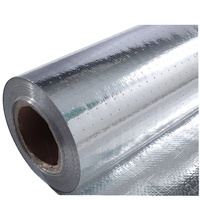

Aluminized Fiberglass Fabric:

The heat shield fabric is made of fiberglass cloth coated with aluminum. The fabric reflects heat away from the hot object. The aluminized layer dissipates heat that passes through the fabric. It is lightweight and flexible. The aluminized layer makes it durable. The fabric is used to make heat shields, fireproof bags, and heat barriers.

-

Fiberglass Cloth:

The fabric is made of fiberglass without aluminum coating. It has high-temperature resistance. The absence of aluminum coating makes it lightweight and cost-effective. The fabric is used to make heat shields and exhaust wraps.

-

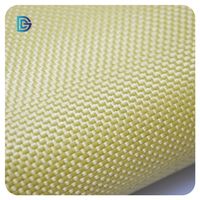

Nomex Fabric:

The fabric is made from aramid fibers. It is lightweight and has high resistance to heat. It can resist up to 370 degrees Celsius of direct heat. Nomex fabric is breathable and comfortable. It is used to make fireproof clothing, aerospace applications, and racing suits.

-

Thermal Blankets:

Heat shield fabrics are woven or non-woven textiles. They are made from materials with high thermal resistance. The materials include fiberglass, silica, ceramic, and para-aramid. The blankets insulate and cover objects that generate heat. They prevent heat from damaging sensitive components. The blankets are reusable and easy to install. They are used in automotive and aerospace industries.

-

Silicone Coated Fiberglass:

The fabric is made of fiberglass with silicone coating on one or both sides. The silicone coating makes the fabric waterproof and more heat-resistant. It can resist up to 260 degrees Celsius of direct heat. The fabric is used to make heat-resistant aprons, fire blankets, and welding curtains.

-

Mylar Sheets:

Mylar sheets are made of polyester film coated with aluminum mylar. The sheets reflect heat and light. They are lightweight and easy to install. The sheets are used in space blankets and emergency heat shields.

Functions and features of heat shield fabric

When looking for heat shield fabric to use as a heat shield for a vehicle, it is important to consider its features and functions to ensure it meets the required standards for the intended use.

-

High temperature resistance:

One of the most important features of a heat shield fabric is its ability to withstand high temperatures without melting or degrading. Most heat shield fabrics can resist extremely high temperatures, usually up to 2000 degrees Fahrenheit. This makes them suitable for use in high-temperature environments such as automotive and aerospace applications.

-

Non-flammability:

A good heat shield fabric should be non-flammable. This means it won't catch fire easily when exposed to high temperatures or sparks. Most heat shield fabrics are manufactured with non-flammable materials or are treated with chemicals to make them non-flammable.

-

Durability:

Durability is an important feature of heat shield fabrics. The heat shield fabrics are usually durable and can withstand wear, tear, and high temperatures. This ensures that they remain functional for a long time, offering optimal heat protection.

-

Lightweight:

Another important feature of the heat shield fabric is its lightweight nature. Most heat shield fabrics are light, making them easy to handle and install. Additionally, their lightweight nature ensures they do not add unnecessary weight to the vehicle or aircraft.

-

Flexibility:

Some heat shield fabrics are flexible, allowing them to be easily installed on curved or irregular surfaces. This feature is important when shielding heat on surfaces that are not straight or rigid.

-

Reflectivity:

Some heat shield fabrics are highly reflective. This allows them to reflect heat away from the protected surface. The reflective nature of these heat shield fabrics offers optimal heat protection and ensures they remain cool.

-

Breathability:

Some heat shield fabrics have breathable features. This ensures air circulates and prevents the buildup of moisture or heat. The breathable feature is important as it prevents mold from growing and keeps the heat shield fabric in good condition.

Scenarios of heat shield fabric

-

Automotive Applications

Under the Hood: Heat shield fabrics are often used to create heat shields for sensitive electronic components, wiring harnesses, and fuel lines. These heat shields protect components from high temperatures generated by the engine and exhaust systems.

Engine Covers: These fabrics are also used in engine covers, commonly known as hood liners or bonnets. They help reflect heat away from the engine bay, keeping the hood cooler and protecting paint and plastic components from heat damage.

-

Aerospace and Aviation

Thermal Protection Systems: Heat shield fabrics are critical in aerospace applications, particularly in thermal protection systems (TPS) for spacecraft. The fabrics are used in ablative heat shields that protect spacecraft during re-entry into the Earth's atmosphere.

Engine Compartment Insulation: These fabrics are used in aircraft to insulate sensitive components and systems from heat generated by the engines. This insulation helps maintain optimal operating temperatures for electronic systems and prevents heat damage to components.

-

Motorcycles

Exhaust Insulation: Motorcycle exhaust systems can reach extremely high temperatures. Heat shield fabrics are used to create heat shields that protect riders and passengers from burns, especially on areas like the rear fenders and swingarms.

-

Industrial Applications

High-Temperature Environments: Heat shield fabrics are employed in various industries, such as metalworking, glass manufacturing, and foundries. They are used to create heat shields that protect personnel, equipment, and flammable materials from radiant heat in high-temperature environments.

Welding and Cutting Operations: These fabrics are used to shield adjacent areas from heat and sparks during welding, cutting, or brazing operations. This helps prevent fires and heat damage to nearby structures or materials.

-

Marine Applications

Engine Compartment Insulation: Heat shield fabrics are used in marine vessels, such as boats and ships, to insulate engine compartments and prevent heat transfer to other parts of the vessel, such as the hull or living quarters.

Exhaust Insulation: These fabrics are also used to insulate and shield exhaust systems from heat-sensitive components, such as wiring, fuel lines, or plastic parts.

-

Consumer Electronics

Heat Dissipation: While not traditional heat shielding, reflective fabrics can be used in consumer electronics, such as laptops and tablets, to help dissipate heat from internal components and maintain optimal operating temperatures. By reflecting heat away from the device's exterior, they can prevent overheating and improve performance.

How to choose heat shield fabric

When looking for heat shield fabric, there are several factors to consider to ensure that the product meets the customer's needs. Here are some of them:

-

Durability

It is important to consider the durability of the heat shield fabric, especially if it will be used in harsh environments. A durable fabric will be able to withstand wear and tear and extreme temperatures. This will ensure longevity and reliable performance.

-

Weight and thickness

The weight and thickness of the heat shield fabric will affect its performance. A heavier or thicker fabric may provide better heat protection. On the other hand, a lighter or thinner one will be more flexible and easier to work with. Buyers should choose a weight and thickness that will be suitable for their intended application.

-

Application

The fabric can be used for different applications, including automotive, aerospace, industrial and marine use. Each application will have unique requirements and buyers should choose a fabric that will be suitable for their intended use.

-

Material

Heat shield fabrics are made from different materials, such as fiberglass, aluminum, titanium and ceramic. Each material has its own pros and cons. Fiberglass is ideal for high-temperature applications while aluminum is lightweight and easy to work with. It is important to choose the right material to achieve the desired level of heat protection.

-

Breathability

If the heat shield fabric will be used as a protective garment, it is important to consider its breathability. A breathable fabric will allow air to circulate and prevent overheating.

-

Water resistance

Water-resistant fabrics will be more versatile and easier to maintain. However, this may not be necessary for all applications.

-

Ease of installation

Buyers should consider the ease of installation when choosing heat shield fabrics. Features like sewing, welding and adhesive will make the installation process easier.

heat shield fabric Q and A

Q1: What is a heat shield fabric?

A1: A heat shield fabric is a material designed to resist or reflect high temperatures. It's often used in automotive, aerospace, and industrial applications to protect sensitive components from heat.

Q2: What are the common types of heat shield fabrics?

A2: The common types include aluminized fiberglass, Kevlar, Nomex, and titanium fabrics. Each type has unique heat-resistant properties and is used for specific applications.

Q3: How is a heat shield fabric maintained?

A3: Most heat shield fabrics are easy to maintain. They can be wiped clean with a damp cloth. In case they get heavily soiled, they can be cleaned with mild soap. It's not recommended to machine wash or tumble dry the heat shield fabric.

Q4: Can a heat shield fabric be customized?

A4: Yes, many manufacturers offer customizable heat shield fabrics. Customers can choose the size, shape, material, and additional features according to their needs.

Q5: Is a heat shield fabric waterproof?

A5: Not all heat shield fabrics are waterproof. While some may resist water, the primary function of a heat shield fabric is to withstand or reflect heat. Waterproof fabrics should be requested specifically.