hf spindle

hf spindle

hf spindle

hf spindle

hf spindle

hf spindle

hf spindle

hf spindle

hf spindle

hf spindle

hf spindle

hf spindle

hf spindle

hf spindle

hf spindle

hf spindle

CNC LY High Quality Machine Tool Spindle Is Used for Cutting the Side Holes of the Engraving Machine

hf spindle

hf spindle

hf spindle

hf spindle

Types of hf spindles

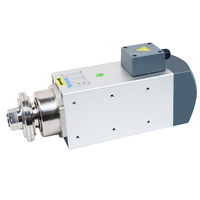

An hf spindle is an electric motor designed to meet the needs of various high-frequency spindles. Generally speaking, an HF spindle is a small, high-speed, water-cooled spindle motor designed for CNC machines. The high-frequency spindle motor is one of the important accessories of the CNC engraving machine. High-frequency motors have many small diameters and weights. They are mostly used for engraving suites, aluminum products, drinking water cups, crystal, and other industries. They can be applied to various materials like wood, plastic, and PVC.

Some types of hf spindles are as follows:

-

Air-Cooled High Frequency Spindle:

-

Water Cooled High Frequency Spindle:

-

Direct-drive High Frequency Spindle:

-

Torque-controlled High Frequency Spindle:

An Air-Cooled High Frequency Spindle releases the heat generated by the spindle during work through the cooling fins on the spindle under the influence of airflow, which comes from the spindle wheel's rotation. It has a simple structure, convenient installation, and low maintenance cost. However, its heat dissipation ability is limited, which is easy to cause spindle overheating and affect its stable operation and service life.

The heat generated during the work of the Water-Cooled High Frequency Spindle is dissipated through the coolant's circulation (usually distilled water or a water-conductive cooling liquid). It has excellent heat dissipation performance, which can maintain the spindle's high speed and stability for a long time. It can adapt to high-intensity continuous work and high-speed machining, thus improving its service life. However, it needs to install a water cooling system that may cost more and require regular maintenance of the cooling system.

The motor of a Direct-drive High Frequency Spindle directly drives the spindle without any transmission mechanism. It has a simple structure, high reliability, and low maintenance requirements. Furthermore, it has a rapid start-up and stop response speed and excellent acceleration and deceleration performance. However, they may cost and require higher power to overcome the torque caused by inertia.

Torque-controlled High Frequency Spindles regulate their speed and output torque by controlling the spindle motor's torque. It has a high control accuracy and flexible adjustment range, which can meet the processing requirements of different materials and shapes. High Frequency Torque Spindles also have a good stability and repeatability, suitable for high precision and high quality machining occasions. However, it may cost more and need more advanced control system and drive device to realize its control function.

Specification and maintenance of hf spindles

These are some typical specifications along with their maintenance requirements for a high-frequency spindle used in CNC machines:

-

Power rating

High-frequency spindles are available in various power ratings to suit different applications. Common power ratings range from 0.5 kW up to over 10 kW.

Maintenance: The power rating is related to the spindle's design. There are no specific maintenance requirements associated with the power rating. However, if the spindle is more powerful than necessary for the application, it may be subjected to higher loads. This could lead to a shorter lifespan. Power ratings should be matched appropriately to avoid this.

-

Speed

Spindles can have maximum speeds from around 50,000 RPM up to 300,000 RPM or higher, depending on the model. Maintenance: Spindle speeds should be chosen to match the material and type of machining being done. If operating at the spindle's maximum speed for long periods, ensure sufficient cooling and lubrication are provided. Regularly inspect the spindle's bearings and rotors for signs of wear from high-speed operation.

-

Tool holder

Spindles are designed to accept certain types of tool holders, like ER collet holders or HSK holders. The tool holder type affects how tools are held and changed. Maintenance: Keep the tool holder interfaces clean. Inspect for signs of wear or damage. The maintenance schedule must be followed closely to avoid any issues with the tool holder's function.

-

Cooling System

Spindle cooling prevents overheating during operation. Options include air cooling, water cooling, or other methods as specified by the manufacturer. Maintenance: Ensure the cooling system is working properly. For water-cooled spindles, check the water flow and concentrations regularly. On air-cooled spindles, make sure the fan is running. Fans and radiators should be cleaned of dust/fan blades periodically.

Applications of high-frequency spindles

HF spindle motors are popular in woodworking and engraving industries. With the growing popularity of high-frequency spindle motors, their applications are growing. Now, the high-frequency spindle motor is applicable in the following industries:

- Woodworking industry:The hf wood spindle motor is widely used in the woodworking industry. Woodworking industries use high-frequency spindle motors for cutting, drilling, engraving, milling and routing wood materials. The wood material includes solid wood, plywood, MDF, and foam board. The advantage of using a high-frequency spindle motor is that woodworkers can achieve precise and smooth edges on their woodwork projects.

- Advertising industry:In the advertising industry, high-frequency spindle motors are used in CNC engraving machines to work on various materials. Advertising professionals use the motors to cut, engrave, and mark different materials like acrylic, PVC, aluminum, and brass. High-frequency spindle motors with high speeds offer precise engraving and cutting. This ensures that advertising professionals achieve high-quality signage and dedication with great ease.

- Stone industry:High-frequency spindle motors are commonly used in the stone industry to cut and polish stone materials. The motors offer high torque. This gives the spindle the ability to handle tough stone materials and provide precise control. Stoneworkers achieve smooth cuts and excellent finishes on stone materials such as granite, marble, and porcelain.

- Metals industries:Spindle motors are used in the metals industry along with CNC machines. This enables the work to cut and polish different kinds of metal materials like copper, aluminum, stainless steel and brass. The metals industry achieves high cutting precision and smooth results on the metal materials using motors with high speed and torque. High-frequency spindle motors are compatible with standard CNC automation. As a result, they can be integrated into automated manufacturing processes.

- Electronics industry:In the electronics industry, a high-speed spindle motor is widely used in micro-drilling applications. Electronics manufacturers prefer the motor because it supports precise drilling of small holes in PCBs and other electronic components. Also, the motors offer high-speed operation, which helps to increase overall production efficiency.

How to choose HF spindles

When choosing an HF spindle for a CNC machine, it is essential to consider several factors.

- Spindle's power: Higher power spindles have a higher torque and can work with existing tool holders. Higher power spindles allow users to process a wider selection of materials and reduce work time. For woodworking, a 1.5kw HF spindle is commonly used. For processing metals like aluminum or copper, a 2.2kw or higher power spindle is better.

- Speed range: An HF spindle with a higher speed gives more torque. It can cut through materials faster. In woodworking, a 3.5 to 5.5 kw spindle with a speed of 6-24hz is preferable. A 12kw HF spindle with a maximum speed of 15000hz is used to process metals like aluminium, steel, rubber, copper, etc.

- Automatic tool change: An air-cooled HF spindle can use an automatic tool changer with HSD or ISO tool holder standards. HSD tool holders are common in woodworking applications, while ISO holders are for metalworking. An automatic changer increases productivity by changing tools during a work process without manual input.

- Water-cooled spindles:Consider using a water-cooled spindle if the CNC machine runs a longer time and at higher speeds. Its efficient cooling system can operate at high speeds. It also has a low noise level. A water-cooled spindle requires the investing of a water mist support system for its cooling needs.

- Machine compatibility: HF spindle must fit the existing tool holder on the CNC machine. Check if the spindle can accommodate the present tool holder or if any adapters are required to make it compatible.

hf spindle FAQ

Q1: How does an HF spindle differ from air-cooled and water-cooled spindle motors?

A1: The high-frequency spindle motor is similar to the air-cooled and water-cooled spindle in appearance. However, there is no housing on the HF spindle to dissipate heat into the surrounding air. An HF spindle usually has a higher power rating than air-cooled spindles. Water-cooled spindles have great cooling systems. They use an internal liquid coolant and an external thermal sink to dissipate heat. It works great in high-power applications.

Q2: What are the bearing types of HF spindles?

A2: High-frequency spindle motors usually use two kinds of bearings: hybrid ceramic and full ceramic.

Hybrid ceramic bearings have steel rings and ceramic balls. High-frequency steel rings provide durability and long life. Full ceramic bearings have both rings and balls made of ceramics. They are suitable for higher temperatures and dust-resistant environments.

Q3: Can an HF spindle be used with different collets for various cutter shanks?

A3: Yes. The high-frequency spindle can be used with different collets, such as ER collets. They can accept cutter shank sizes from small to large.

Q4: Does HF spindles have circuit boards?

A4: Yes. Some high-frequency spindles have circuit boards. An HF spindle with a circuit board may have features like automatic tool changers and overload protection. Different circuit boards support different functions.

Q5: What's the connection between an HF spindle and the router?

A5: An HF spindle is similar to a router in its physical shape. Both have a housing that contains a motor. However, an HF spindle has a higher power density than a conventional router. It provides a more consistent and smoother output torque.