honey separator

honey separator

honey separator

honey separator

honey separator

honey separator

honey separator

honey separator

honey separator

honey separator

honey separator

honey separator

honey separator

honey separator

honey separator

honey separator

honey separator

honey separator

honey separator

honey separator

honey separator

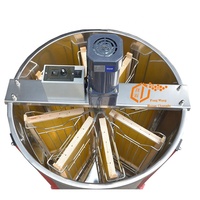

Types of Honey Separator

A honey separator is an equipment used to extract raw honey from honeycombs while keeping the wax and other impurities separated. There are two common types of honey separators based on the method of operation: centrifugal honey separators and gravity honey separators.

- Centrifugal Honey Separator: A centrifugal honey separator is an apiary equipment that utilizes the centrifugal force generated by the rotating drum to separate honey from the combs. It usually comes with a manual or electric motor crank. To use a centrifugal honey separator, the beekeeper places the frames into the basket after cutting the wax cappings from the honeycomb. Then, they close the lid securely, ensuring that it is not too tight, and start turning the handle. As the centrifugal separator spins the basket, wax and honey will be flung out of the honeycomb frame walls into the collection container through the perforated spinning basket walls. A centrifugal honey separator can be further categorized into two types: radial and tangential honey separators. A radial honey separator has its honeycomb frame holder spun around the axis of the drum in a circular motion. The honey separator draws out honey from honeycomb frames that are inserted into the basket radially located at the center. In contrast, a tangential honey separator spins its honeycomb frame holder tangentially to the drum in a straight line. The frame holder needs to be stopped and reversed for the honey to be extracted from both sides of the honeycomb.

- Gravity Honey Separator: A gravity honey separator is an apiary equipment that takes advantage of gravity to separate unprocessed honey from wax and other impurities. Usually, wax is lighter than honey, and with the help of gravity, the honey flows and settles at the bottom while the wax floats on top. A typical gravity honey extractor consists of a funnel-shaped container, filtering mesh, and a tap. Using a gravity honey separator is easy. The first step is to position the container so that the tap is at an accessible point to open. Then, the filtering mesh is placed strategically over the container, and the tap is opened. Finally, the honey is processed as it flows through the mesh and out of the tap. Although gravity honey separators may not come with manual or electric cranks, they are more affordable options for beekeepers with small hives.

Specification and maintenance of honey separators

Honey extractors have two fundamental specifications: capacity and power or motor strength. Capacity affects how many frames an extractor can handle in a single cycle. Each frame has a different size, so manufacturers often illustrate capacity using common beehive frame sizes, for example, 4/8 (which means it can accommodate four overhead frames but eight under frames) or two 10-frames. The extractor's shape also influences its capacity calculations. Generally, more giant, cylindrical extractors can hold more honey than taller extractors.

Transforming the centrifuge's fastness into power is a simple formula: Power = Torque x Angular Speed. Torque is the rotational force, and angular speed is the rotational speed. Torque is determined by the honey separator's diameter. For honey extractors, speed is usually between 200 and 500 per minute. Power is more critical with motor-driven centrifuges, such as electric honey extractors. Some specifications may show it in Watts. Honey separator motors are typically 24V, 250-300W, and speed is crucial so that the honey extractor can efficiently separate honey from honeycomb cells at a higher level.

Hygiene in a professional setting is something that should never be overlooked. Cleaning and maintenance of a honey centrifuge separator begins with washing all parts with hot water to ensure that no honey remains. The honey separator should be wiped dry, moved to a clean, dry honey house, and stored out of sight of likely contaminants. Many people choose to cover the separator with a large piece of clean and unused cardboard.

Honey separators should be cleaned with hot, soapy water and inspected for rust on separators made of stainless steel. Pay careful attention to hose connections. If present, brass fittings should be lubricated with food-grade grease. Rust spots on stainless steel should be removed with non-abrasive stainless steel cleaner and a cloth. We recommend shutting off the water valve and taking a valve bucket, as it is easier to clean the extractor this way. Cleaning should begin at the bottom of the bucket. Please remember that water helps to spread the honey.

For electric honey extractors, we need to ensure all electrical parts are cleaned. Honey extractors should not be used for honey that has been crystallized, as doing so can break the motor.

Scenarios

Honey extractors can be used to separate honey from honeycombs efficiently. Here are some usage scenarios for honey separators:

-

Beekeeping Operations:

Honey separators are used by professional and hobbyist beekeepers to extract honey from honeycombs. After the bees have capped the honeycomb, beekeepers use the honey separator to harvest the honey for sale or personal use. Honey separators for beekeepers come in various capacities to suit different volumes of honey production.

-

Honey Processing Facilities:

Commercial honey processing facilities use honey separators to extract honey from large volumes of honeycombs. The honey separator allows processing facilities to efficiently extract honey, filter out impurities, and package the honey for retail or wholesale distribution.

-

Permaculture and Sustainable Farms:

Farms that incorporate beekeeping for honey production, pollination, or other ecological benefits may use honey separators. Honey separators enable these farms to manage honey production on-site and integrate honey into their farm operations.

-

Honey Production Workshops:

Honey production workshops or educational programs teach individuals how to keep bees and produce honey. During the hands-on training, instructors may use a honey separator to demonstrate the process of extracting honey from honeycombs. Participants can learn beekeeping and honey extraction techniques.

-

Research and Development:

Honey Separators are used by research institutions, agricultural universities, or bee health organizations to study honeybee behavior, honey production, or beekeeping practices. Extractors with specific features for research purposes may be used to collect data, conduct experiments, or develop new beekeeping techniques.

How to choose honey separators

-

Consider the operating process.

The systems of honey separators include feeding systems, collecting honey tanks, stirring systems, filtering systems, discharging systems, and operating platforms, among others. Observe the operating process of the honey separator and choose the model that matches the desired operating processes.

-

Capacity of honey separators

When choosing the right honey separator, carefully consider its capacity. Demand in specific situations should be weighed against small- and large-capacity separators.

For primary processing, small-capacity honey separators with a capacity of approximately 60 kg per hour for honey extraction, which have a reasonable cost and meet the requirement, are enough.

For further processing or a more significant amount of honey, large-capacity honey separators honey extractor, such as the 1000 kg per hour for honey extraction or higher, should be taken into account.

-

Quality of honey separators

Selecting a honey separator with a high-quality, durable material is essential. Honey separators made of stainless steel are robust and long-lasting. It's also essential to consider the production process and the separator assembly quality. A smooth surface and well-joined parts of a honey separator will help prevent honey from being contaminated during the extraction process.

Honey separator Q & A

Q: What is a honey separator used for?

A: A honey separator is a device that uses centrifugal force to separate honey from honeycombs based on density. It is also called a honey extractor. A honey separator can separate honey from the combs quickly and conveniently. It protects the intact structure of the combs, allowing beekeepers to let the bees rebuild them.

Q: How does a honey separator work?

A: Honey separators have a rotating drum inside powered by an electric motor or manually turning a handle. Beekeepers pour the unfiltered honey into the drum. The drum spins, and the honey gets thrown against the side of the barrel. The force of gravity causes the honey to separate from the comb and then flow out of the drum.

Q: What are the two main types of honey separators?

A: The two main types of honey separators are radial and axial honey separators. Radial honey separators have a drum that rotates around its central axis. Uncapping honeycombs are placed on a rotating rack in the honey separator. When the rack spins, the honeycomb is flung outwards, and the honey is separated. In an axial honey separator, the uncapped honeycombs are placed vertically. The unidirectional or bidirectional spinning motion separates the honey from the comb.

Q: What is the difference between a honey extractor and a honey separator?

A: The process is different. A honey extractor uses centrifugal force to extract honey from honeycomb cells instead of separating the honey based on density, like a honey separator. In a honey extractor, the honeycomb frames are placed inside, and the honeycomb centrifuges. Honey extractors are radial or tangential, just like honey separators. Honey extractors are more commonly used in small to medium-scale honey production compared to honey separators.