inconel 601 pipe

inconel 601 pipe

inconel 601 pipe

inconel 601 pipe

inconel 601 pipe

inconel 601 pipe

inconel 601 pipe

inconel 601 pipe

inconel 601 pipe

inconel 601 pipe

inconel 601 pipe

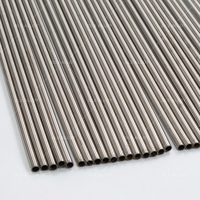

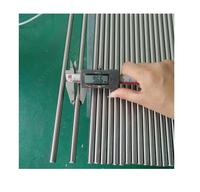

Hot Sale ASTM Monel 400 UNS 4400 K500 Inconel 939 601 600 Bright Nickle Alloy Pipe/Tube Price Per kg

inconel 601 pipe

inconel 601 pipe

inconel 601 pipe

inconel 601 pipe

inconel 601 pipe

inconel 601 pipe

inconel 601 pipe

inconel 601 pipe

inconel 601 pipe

inconel 601 pipe

Introduction to Inconel 601 Pipe

The Inconel 601 pipe is a high-performance material known for its exceptional heat and corrosion resistance. As an essential component in various industrial applications, Inconel 601 is an alloy that combines nickel, chromium, and iron, making it perfectly suited for environments exposed to extreme temperatures and aggressive chemicals. This product is particularly favored in industries such as aerospace, chemical processing, and power generation due to its reliability and durability.

Types of Inconel 601 Pipe

Inconel 601 pipes come in different forms to accommodate specific application needs. Here are the main types:

- Seamless Pipes: These are formed without a seam, providing a smooth interior surface and greater strength.

- Welded Pipes: Manufactured by welding together flat pieces of metal, this type is often used where high pressure is not a major concern.

- Fabricated Pipes: These are custom-made pipes that can be designed to specific dimensions and requirements for unique applications.

- Plain-End Pipes: These pipes come without any end preparation, ideal for applications that do not require connections.

Applications of Inconel 601 Pipe

The versatility of Inconel 601 pipe allows for numerous applications across various sectors:

- Aerospace: Used in gas turbine components and heat exchangers, where high temperatures and oxidation are prevalent.

- Chemical Processing: Essential for manufacturing environments where corrosive substances are involved, as it resists oxidation and scaling.

- Power Generation: Employed in coal-fired boiler applications and nuclear reactors due to its handling of high temperatures.

- Heat Treatment: Employed in furnace applications and other environments where thermal stability is critical.

Features and Advantages of Inconel 601 Pipe

The Inconel 601 pipe boasts a multitude of features and advantages that make it a preferred choice among industrial professionals:

- Corrosion Resistance: Exceptional resistance to oxidation and carburization at elevated temperatures, ensuring longevity and reliability.

- High-Temperature Stability: Retains strength and structural integrity even in extreme heat conditions, outperforming many other materials.

- Ease of Fabrication: Can be easily welded, bent, and fabricated, making it a versatile choice for custom applications.

- Good Mechanical Properties: Offers high tensile strength and flexibility, allowing it to withstand rigorous operational demands.

- Non-magnetic: The non-magnetic properties of Inconel 601 make it suitable for applications that require magnetic neutrality.

Conclusion

In conclusion, the Inconel 601 pipe is a remarkable solution for industries requiring materials that combine heat and corrosion resistance alongside mechanical strength. With its varied types and extensive applications, it meets the diverse needs of modern industrial operations. Choosing Inconel 601 ensures that you are investing in a product designed to withstand the most demanding environments, making it a worthwhile addition to any industrial setting.