insulated aluminum roof panels

insulated aluminum roof panels

insulated aluminum roof panels

insulated aluminum roof panels

insulated aluminum roof panels

insulated aluminum roof panels

insulated aluminum roof panels

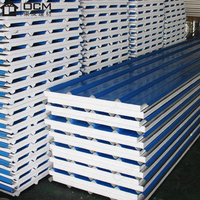

Wholesale Price Pu Pir Roof Insulated Aluminium Sandwich Panel for Warehouse Buildings Made in China

insulated aluminum roof panels

insulated aluminum roof panels

insulated aluminum roof panels

insulated aluminum roof panels

insulated aluminum roof panels

insulated aluminum roof panels

insulated aluminum roof panels

insulated aluminum roof panels

insulated aluminum roof panels

insulated aluminum roof panels

insulated aluminum roof panels

50-150mm Pu Insulated Polyurethane Sandwich Exterior Wall Panel Eps Pir Corrugated Roof Steel Panels

insulated aluminum roof panels

insulated aluminum roof panels

insulated aluminum roof panels

Types of insulated aluminum roof panels

Insulated aluminum roof panels are a popular choice in the construction industry because they provide an excellent combination of strength, lightweight, and insulation properties. These panels are commonly used in industrial, commercial, and residential applications. Insulated aluminum roof panels come in different types, including;

-

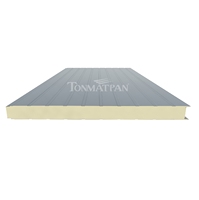

Sandwich panels

Insulated aluminum roof panels are also called aluminum insulated panels or aluminum panels. They consist of three layers: two aluminum sheets and a core material sandwiched between them. The core material can vary, affecting the panels' thermal and acoustic insulation properties. Common core materials include polystyrene foam (EPS), polyurethane foam (PUR), and mineral wool (MW). The choice of core material depends on factors like the required insulation value, fire resistance, and environmental considerations.

-

Composite panels

Insulated aluminum roof panels are made of two different types of panels. They have a thin layer of aluminum on the roof and a thicker layer of aluminum on the bottom. In between these two aluminum layers is a core material that helps insulate the building from heat and cold. The core material can be styrofoam, polyurethane foam, or mineral wool. Styrofoam is a good choice when weight is important because it is lighter. Polyurethane foam works better for insulation since it keeps heat and cold from passing through. Mineral wool is chosen when fire safety is a concern because it won't catch on fire easily. The steel sheets on top and bottom make these panels strong and durable since aluminum doesn't rust like steel would.

-

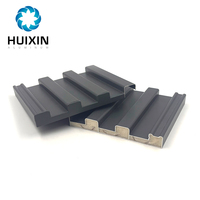

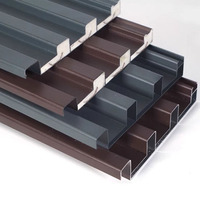

Concealed fastener panels

These panels have their attachment points hidden under the panels. This makes them look smooth and neat because nothing is sticking out. Since the fasteners are not exposed, these panels are less likely to leak water. They also block the wind from making noise because the wind goes over the fastener and not through the panels. Because the wind can't get into the holes made by the fasteners, these panels also help keep buildings quieter. Since the fasteners are covered, these panels are better at keeping the wind from blowing through the cracks. This helps buildings stay warmer or cooler for longer because the panels seal the building better.

Function and Feature of Insulated Aluminum Roof Panels

Insulated aluminum roof panels are prefabricated roofing materials with multiple uses, including:

- Insulated aluminum roof panels for homes: Aluminum insulated panels for roofing are commonly used in residential roofing applications. They provide essential weather protection for homes while also offering insulation and energy efficiency. These panels create a comfortable living space for homeowners and reduce energy costs.

- Insulated aluminum roof panels for commercial buildings: Insulated aluminum panels are widely used in commercial building applications. They provide a durable and low-maintenance roofing solution that protects against harsh weather. The energy efficiency of these panels also helps commercial building owners save on heating and cooling costs.

- Insulated aluminum roof panels for agricultural buildings: Aluminum insulated panels for roofing are also used in agricultural buildings such as barns, stables, and storage facilities. The durable construction of these panels protects farm equipment and livestock from harsh weather. They are also easy to clean and maintain, making them a practical choice for agricultural settings.

- Insulated aluminum roof panels for industrial facilities: Industrial facilities, such as warehouses and factories, use insulated aluminum panels. The panels provide a strong and weather-resistant roof that protects valuable inventory and machinery. The insulation properties of the panels help maintain a consistent temperature within the facility, improving energy efficiency.

- Insulated aluminum roof panels for recreational structures: Recreational structures, such as stadiums, arenas, and community centers, can also be roofed with insulated aluminum panels. The panels provide a long-lasting and low-maintenance roof that withstands harsh weather. The energy efficiency of the panels also helps reduce the overall operating costs of the facility.

Some features of insulated aluminum roof panels include:

- Strong and lightweight: Aluminum is a durable and lightweight material. It is as strong as steel but less dense. This makes insulated aluminum panels for roofing easy to handle and install.

- Resistance to rust and corrosion: Aluminum does not need to be painted to prevent rust. It makes insulated aluminum roof panels last many years with little maintenance.

- Thermal insulation: The panels have foam insulation sandwiched between the metal sheets. This foam insulation keeps houses cooler in summer and warmer in winter.

- Energy efficiency: Some insulated aluminum panels have a reflective coating. This coating bounces heat away from the building. It helps keep buildings cool in hot weather.

- Quick and easy to install: Roof panels can be prefabricated in custom sizes. They are also joined using locking systems. This makes roofs easy to install and reduces labor costs.

- Minimal maintenance: The smooth surface of insulated aluminum roof panels is easy to clean. Aluminum also resists rust, so owners do not have to paint the panels to prevent rust.

Scenarios of Insulated Aluminum Roof Panels

Insulated aluminum roof panels are versatile and can be used in different industries. Here are some common application scenarios:

-

Residential Buildings

Insulated aluminum roof panels are ideal for residential homes. The insulated panels regulate temperatures, reducing energy consumption. Additionally, the roofs are durable and require minimal maintenance.

-

Commercial and Industrial Buildings

Insulated aluminum roof panels are used in warehouses, factories, shopping malls, and office buildings. The roofs are cost-effective for large-scale projects. Besides, they offer long-term value due to their durability. The insulated panels provide thermal insulation in commercial spaces. This creates a comfortable working environment and reduces air conditioning costs.

-

Recreational Facilities

Insulated aluminum panels are used as roofs for stadiums, sports halls, and event centers. The roofs are spacious and have continuous aluminum sheets. This ensures the structural integrity of the roof. Additionally, the insulated panels are weather-resistant. They protect the facilities from extreme weather conditions. More importantly, the panels are energy-efficient. They minimize heat loss or gain and reduce energy costs.

-

Agricultural Buildings

Insulated aluminum panels are used in barns, storage sheds, and greenhouses. The roof panels are durable. They protect livestock and agricultural equipment. More importantly, the insulated panels maintain stable temperatures. This protects produce and extends the shelf life of perishable goods.

-

Transportable Structures

Insulated aluminum panels are used in mobile homes, container houses, and temporary buildings. The insulated panels are lightweight. This reduces the overall weight of the structure. Additionally, the panels are easy to assemble and disassemble. This makes them ideal for temporary structures or when relocating a mobile home.

-

Specialized Facilities

Insulated aluminum panels are used in hospitals, laboratories, and data centers. The panels provide a clean environment. They are easy to wash and maintain. Moreover, the insulated panels regulate temperatures. This ensures the safety and integrity of sensitive equipment and perishable items like medical supplies.

How to choose insulated aluminum roof panels

When choosing the insulated aluminum panels for a project, there are several factors that must be considered. This includes:

-

Consider the project need

Before anything else, it is important to clearly define needs and project requirements. What kind of building is it? A home? A factory? A school? A storage unit? The building type will greatly influence the kind of insulated metal roofing panels that need to be purchased. For example, if it's a home, then home-appropriate roofing panels should be purchased. Consider also the climate where the building is located. Is it hot? Cold? Rainy? This will help determine the kind of insulation required. For example, a cold area needs panels with more insulating foam.

-

Consider the thermal performance

When buying insulated aluminum roofing panels for any building, it is important to look at the R-value. The R-value measures how well insulated the panel is. The higher the R-value, the better insulated the panel is. This means the building will stay cooler or warmer, depending on the weather, without using a lot of power. For colder climates, insulated panels with a high R-value should be got. The R-value is crucial for energy savings.

-

Consider the quality of the panels

The first thing to check is the thickness of the aluminum. Thicker aluminum means stronger roofing panels that will last a long time. Then check how the panels are made. Well-made panels with good welding will hold up better than cheaply made ones. Also, consider the warranty being offered. A longer warranty means more confidence in the product's quality. All this makes sure the panels will perform well.

-

Consider the weight of the panel

When buying insulated aluminum roofing panels for a building, it is important to consider the weight of the panels. In general, lightweight panels are easier to handle and install. This means that less money will be spent on labor. On the flip side, heavier panels are often more durable and stable once installed on the roof. They can withstand wind and other weather better than lighter panels. As such, it is important to consider the weight of the panel versus the stability once the panel is installed.

insulated aluminum roof panels Q&A

Q: What are insulated aluminum roof panels and how are they used?

A: An insulated aluminum roof panel consists of an aluminum sheet bonded to a layer of insulation material. It is used as a roofing system in buildings to provide shelter and aluminum's durability and corrosion resistance. The insulation helps regulate indoor temperatures and reduce energy costs.

Q: What are the advantages of insulated aluminum roof panels?

A: Some of the advantages include: they are lightweight and durable, provide excellent thermal insulation, and come in various colors and finishes. They are also low maintenance and have a long lifespan.

Q: What are the disadvantages of insulated aluminum roof panels?

A: They include: insulated aluminum panels may not be as strong as steel panels, and they can be more expensive than other types of insulated panels. Aluminum conducts heat, so uninsulated areas may cause heat loss or gain.

Q: Are insulated aluminum roof panels easy to install?

A: Yes, insulated aluminum roof panels are generally easy to install. They are lightweight and can be installed using simple methods like screwing or bolting. However, proper installation is crucial to ensure a weather-tight roof and maximize the panels' thermal performance.

Q: How should insulated aluminum roof panels be maintained?

A: The insulated aluminum panels should be cleaned regularly with water and mild detergent to remove dirt and debris. This prevents corrosion and maintains their appearance. Inspect the panels for damage and repair as needed. Remove any loose paint and touch up with paint approved by the panel manufacturer.