interlock brick

interlock brick

interlock brick

interlock brick

interlock brick

interlock brick

interlock brick

interlock brick

interlock brick

interlock brick

interlock brick

interlock brick

interlock brick

interlock brick

interlock brick

interlock brick

interlock brick

interlock brick

interlock brick

interlock brick

interlock brick

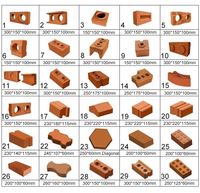

Types of interlock bricks

Interlock bricks are unique bricks that can create a stable and interlocking surface without the use of mortar joints. They can be integrated into traditional and modern architectural designs. The use of interlock bricks can be traced back to the ancient Roman period, and they have made a significant comeback in the machinery industry due to their many advantages.

-

Cement interlock bricks

Cement interlock bricks are often used in the construction of residential and public buildings. They are typically three to five feet long, two to three feet wide, and up to one foot high. Their shapes vary depending on the manufacturer's specifications, but they have unique patterns that allow them to fit together tightly. Cement interlock bricks are made by mixing cement, sand, and water, then pouring the mixture into molds where it will harden before being removed from the mold. Unlike traditional cement blocks, which require mortar between each block for stability, cement interlock bricks lock into place. Therefore, they are easier to install than standard cement blocks, making them an attractive option for DIYers.

-

Plastic interlock bricks

Plastic interlock bricks are an eco-friendly solution for creating stable surfaces. They are made from recycled plastic, which helps reduce plastic waste in landfills and oceans. Plastic interlock bricks come in various colors and designs, giving users the freedom to make personalized and aesthetically pleasing places. Additionally, plastic interlock bricks are lightweight and simple to install, making them the ideal choice for people who aren't particularly skilled or who want to complete a project quickly.

-

Soil interlock bricks

Soil interlock bricks are made from stabilized compressed earth blocks (CEBs). Raw materials extracted locally are used to make these bricks, which makes them a good, sustainable choice that supports the neighborhood economy. Soil interlock bricks are produced by mixing soil, cement, and water, which are then compressed to form the bricks. They are a cost-effective option for constructing pavements and walls.

Specifications and Maintenance of Interlock Bricks

Specifications

-

Sizes and Shapes

Interlock bricks typically come in standard rectangular forms, such as 225x112.5x75mm, 275x215x115mm, and other similar dimensions. The variation of shapes may include larger blocks for building cores or thinner, denser variants for facade construction.

-

Color and Texture

Interlock bricks are available in several hues, including the traditional red or brown, which is formed through iron oxide, and other formulations that utilize differing raw materials. Surface options comprise smooth, rough, embossed, frosted, or any format that provides sufficient grip for pedestrian traffic.

-

Mechanical Properties

The mechanical features of interlock bricks include compressive strength and durability. When creating interlocking bricks, it is essential to choose the appropriate raw materials and firing temperature to ensure their long life spans and ability to support large weights without breaking.

For example, the compressive strength of interlock bricks should typically be more than 7.5 MPa, equivalent to high-strength bricks, while the durability should be equivalent to a minimum of 100 years.

-

Installation Method

The interlock bricks are placed without mortar, and the compressive strength depends on the weight of the traffic.

Maintenance

In many instances, no maintenance is necessary, but if after some years, the interlocking paver stones appear hazy or dirty, the following is the cleaning procedure:

- User can external alkaline based cleaner, which is sodium hydroxide, to remove stains.

- For oil stains, use a degreaser and industrial acid-based cleaner.

- If fungi or algae are present, make use of bleach or sodium hypochlorite.

- For moss, make use of salt or sodium chloride.

- Before cleaning, the entire area to be cleaned should be dampened with water.

- While using chemicals, the instruction manual should be carefully followed.

- After cleaning, it is essential to seal the blocks, and this will stop sand loss from the joints.

It is optional, but it is preferable to apply sand at the joints after cleaning, which is silica sand, and re-compacting the joints with vibrating plate compactor. Some polymers should be used in sand to protect against growth and have better wear resistance.

The sealing of the blocks will help to prevent efflorescent material from being deposited on the surface. It will also aid in surface treatment and make maintenance easier. If the surface of interlocking bricks is not damaged, any solvent-based or water-based sealants should be applied.

Scenarios of interlock bricks

Interlock bricks provide simplistic and sustainable solutions to a variety of industries and infrastructural needs.

-

Construction industry

Due to their precise shapes and sizes, interlock bricks facilitate the rapid and easy construction of buildings, roads, and other infrastructural projects.

-

Affordable housing projects

Interlock bricks are an affordable alternative that may assist in meeting the demand for housing at a low cost and provide a quick construction speed in the case of affordable housing projects.

-

Rural development initiatives

Interlock bricks construction is additionally contributing to poverty reduction and economic growth by ensuring affordable housing for rural populations.

-

Public infrastructure development

In its endeavors to expand the urban infrastructure, the government paved roads with interlock bricks at a low cost and quickly.

-

Environmental rehabilitation projects

Interlock bricks may be used to create sustainable drainage systems or erosion control solutions that fit naturally into the environment in the case of environmental rehabilitation projects.

-

Interactive educational institutions

Educational institutions may use interlock bricks to create interactive and recreational areas that inspire learning and foster creativity among students, such as science and technology parks.

-

Disaster recovery initiatives

In the case of disaster recovery initiatives, interlock bricks can be used to create temporary shelter or permanent housing for displaced populations quickly and effectively.

-

Sports facilities and public spaces

Public spaces play an important role in interlock brick patterns. The patterns of interlock bricks may be combined into various shapes and colors, creating beautiful plazas, parks, and pedestrian streets.

-

Commercial facilities and urban renewal

Interlock bricks are widely used for commercial facilities' exterior and interior decoration as well as urban renewal projects because of their variety of designs and colors.

How to choose interlock bricks

These factors are vital for business buyers who need to select interlocking bricks for storefronts or projects.

-

Soil stabilization required

Focus on interlocking bricks that do not need soil stabilization. It is critical for areas with an unstable soil foundation. Selecting these interlocking bricks can improve stability and save costs by reducing the need for soil stabilization.

-

Architectural appeal

Choose interlocking bricks that can enhance the architectural appeal of different types of buildings. For example, natural stone interlocking bricks can add a touch of luxury to upscale homes or commercial spaces. Modern geometric patterns and colors can create a contemporary aesthetic for urban developments.

-

Project size and budget

Consider the size of the project and budget. In massive projects like public squares or functional city roads, concrete interlocking bricks are often the budget-friendly option for large-scale paving needs. Be mindful of the project size when buying the budget. For smaller, high-impact projects, more expensive options like clay or natural stone can be justified for their unique appearance and durability.

-

Load-bearing capacity

Focus on interlocking bricks with sufficient load-bearing capacities to withstand specific project requirements. Heavy traffic areas like industrial zones, commercial centers, or infrastructure projects need high-load-bearing capacity interlocking bricks. Select those with sufficient load-bearing capacity to ensure long-term performance and avoid premature failure.

-

Supplier reliability and support

Opt for a reliable supplier who offers excellent after-sales support. A dependable supplier ensures consistent stock availability, timely delivery, and compliance with quality standards. Consider the supplier's technical support, installation guidance, and responsive customer service. Choosing a trustworthy supplier with strong support gives added assurance and meets project needs effectively.

Interlock brick FAQ

Q1: Do interlocking bricks need cement?

A1: Interlocking bricks are designed to fit together tightly, creating stable walls without the need for mortar between them. However, using cement at the base and as reinforcement in some sections can be beneficial.

Q2: Do interlocking bricks shrink?

A2: Interlocking bricks typically do not shrink, as they are manufactured to high standards, which include air curing, steam curing, and baking in kilns.

Q3: Do interlocking bricks get heat?

A3: Heat can accumulate in interlocking brick walls because the bricks themselves are not porous enough to allow moisture to pass through. As a result, water vapor cannot evaporate, and heat can become trapped.

Q4: How long does an interlock last?

A4: An interlock made of high-quality material like granite can last for approximately 25 years.