jute machinery

jute machinery

jute machinery

jute machinery

jute machinery

jute machinery

jute machinery

jute machinery

jute machinery

jute machinery

jute machinery

jute machinery

jute machinery

jute machinery

jute machinery

jute machinery

jute machinery

jute machinery

jute machinery

jute machinery

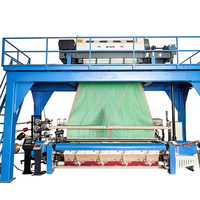

Introduction to Jute Machinery

Jute machinery plays a crucial role in the jute industry, facilitating the processing of jute fibers into various products such as jute bags, textiles, and more. These machines are essential for efficiently carrying out tasks like spinning, weaving, and finishing jute products. One of the key machines in this industry is the jute bag making machine, which automates the production of jute bags and enhances productivity.

Technical Specifications of Jute Machinery

When looking at jute machinery, it's essential to consider various technical specifications. For instance, jute machinery typically has power capabilities ranging from 35-40 hp, enabling it to handle the processing of jute fibers effectively. Additionally, these machines have a maximum range of 3-4 tons, allowing for large-scale production. The length of the machines can vary, with some models reaching between 60 and 130 feet to accommodate different production needs.

Types of Jute Machinery

There are several types of jute machinery available in the market, each serving specific functions in the jute manufacturing process. Apart from the jute bag making machine, other common types include jute bags manufacturing machinery and jute mill machine. These machines are designed to cater to different stages of jute processing, from fiber extraction to the final product finishing.

Design and Features of Jute Machinery

The design of jute machinery is geared towards maximizing efficiency and productivity in jute processing operations. These machines are equipped with advanced features such as automated controls, precision engineering, and robust construction to ensure smooth operation. The jute bag cutting machine, for example, is designed with precision blades and cutting mechanisms to ensure the accurate cutting of jute fabric for bag production.

Advantages of Using Jute Machinery

Utilizing jute machinery offers a range of benefits to manufacturers in the jute industry. One of the primary advantages is the significant increase in production efficiency and output. These machines enable faster processing of jute fibers, leading to higher productivity levels. Moreover, the use of jute machinery ensures consistent quality in jute products, meeting industry standards and customer expectations.

In conclusion, jute machinery plays a vital role in the jute industry, providing manufacturers with the necessary tools to streamline production processes and enhance product quality. By understanding the technical specifications, types, design, features, and advantages of jute machinery, businesses can make informed decisions when investing in these essential machines.