ladle furnace

ladle furnace

ladle furnace

ladle furnace

ladle furnace

ladle furnace

ladle furnace

ladle furnace

ladle furnace

ladle furnace

ladle furnace

ladle furnace

ladle furnace

ladle furnace

ladle furnace

ladle furnace

ladle furnace

ladle furnace

ladle furnace

ladle furnace

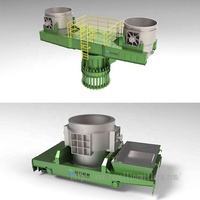

Introduction to Ladle Furnace

A ladle furnace, also known as a ladle refining furnace (LRF furnace), is a crucial piece of equipment in steelmaking processes. This type of furnace plays a vital role in refining molten steel before casting, ensuring high-quality end products. The ladle furnace is widely used in steel plants and foundries to improve the cleanliness and homogeneity of steel.

Technical Specifications and Design

The ladle furnace is designed with advanced features to meet the demanding requirements of the steel industry. It typically has a power capability ranging from 35 to 40 hp, allowing for efficient heating of the molten steel. The furnace can handle ladles with a capacity of 3 to 4 tons, making it suitable for medium to large-scale steel production. Additionally, ladle furnaces come in various sizes, with lengths ranging between 60 and 130 feet to accommodate different production needs.

Operating Principle

The ladle furnace operates by preheating the ladle containing molten steel using graphite electrodes. The electrodes generate intense heat, which is transferred to the steel, raising its temperature to the desired level for refining. During the refining process, various alloys and fluxes can be added to the molten steel to adjust its chemical composition and remove impurities, ensuring the final product meets stringent quality standards.

Advantages of Ladle Furnace in Steelmaking

One of the key advantages of using a ladle furnace in steelmaking is the precise control it offers over the refining process. Manufacturers can adjust parameters such as temperature, stirring, and chemical composition to tailor the steel properties according to specific requirements. This level of control results in higher quality steel with improved mechanical properties and reduced defects.

Applications and Industry Use

Ladle furnaces find extensive use in the steel industry for refining various grades of steel, including carbon steel, stainless steel, and alloy steel. They are employed in both primary steelmaking facilities and secondary refining operations to enhance the properties of the molten steel. Additionally, ladle furnaces are crucial in the production of high-quality steel products for sectors such as automotive, construction, and machinery manufacturing.

Selection and Maintenance of Ladle Furnace

When choosing a ladle furnace for your steel plant or foundry, it is essential to consider factors such as capacity, power rating, and control systems. Selecting the right furnace size and specifications can optimize production efficiency and product quality. Regular maintenance of the furnace, including electrode inspection, refractory lining checks, and temperature calibration, is crucial to ensure consistent performance and prolong the equipment's lifespan.

Overall, the ladle furnace is a critical component in the steelmaking process, offering precise control, high-quality steel production, and versatility in refining operations. Understanding the technical specifications, operating principles, and advantages of ladle furnaces can help businesses make informed decisions when investing in steelmaking equipment.