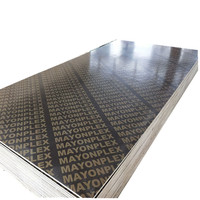

laminated marine plywood

laminated marine plywood

laminated marine plywood

laminated marine plywood

laminated marine plywood

laminated marine plywood

laminated marine plywood

laminated marine plywood

laminated marine plywood

laminated marine plywood

laminated marine plywood

laminated marine plywood

laminated marine plywood

laminated marine plywood

laminated marine plywood

laminated marine plywood

laminated marine plywood

laminated marine plywood

laminated marine plywood

laminated marine plywood

laminated marine plywood

Types of Laminated Marine Plywood

Laminated marine plywood is a type of plywood that is designed specifically for use in marine environments. It is made with multiple layers of veneer that are bonded together with waterproof adhesive, creating a strong and stable panel that can withstand the harsh conditions of moisture and saltwater. Laminated marine plywood is used for a variety of applications in boats and ships, including decking, hull construction, and interior cabinetry. Its smooth surface makes it an ideal choice for marine-grade laminates, which are used to create custom finishes and designs on boats and ships.

There are various types of laminated marine plywood, including:

-

Teak Plywood:

Teak plywood is a type of laminated plywood that is made using teak wood. Teak wood is known for its durability, strength, and resistance to rot and moisture, making it an ideal choice for use in marine environments. Teak plywood is used for various applications, including boat decks, hulls, and furniture. It is valued for its beautiful grain pattern and color, which ranges from golden brown to dark brown. Like laminated plywood, teak plywood consists of multiple layers of veneer, which can be made from various types of wood. These veneers are bonded together with waterproof adhesive to create a strong and stable panel.

-

Poplar Plywood:

Poplar plywood is a type of laminated plywood made with poplar wood. Unlike laminated marine plywood, poplar plywood is not specifically designed for marine use and is typically used for applications where weight is a consideration. For instance, it is commonly used in cabinetry, furniture, and interior walls. It is a lighter and cheaper alternative to laminated marine plywood.

-

Birch Plywood:

This plywood is made with birch wood, which is known for its strength and durability. Birch plywood is not specifically designed for marine use. However, it can be used in applications where stability and strength are required. It is commonly used in cabinetry, furniture, and flooring.

-

HPL Plywood:

High-Pressure Laminated (HPL) plywood is a type of laminated plywood that is made with a high-pressure laminate. The laminate is bonded to the plywood surface under high pressure, creating a durable and wear-resistant surface. HPL plywood is designed for heavy-duty use and is commonly used in countertops, tabletops, and work surfaces.

Features and Functions of Laminated Marine Plywood

Laminated marine plywood has several features that make it an excellent choice for boats and other marine applications. Some of the key features of laminated marine plywood include:

-

High strength and durability

Laminated marine plywood is known for its exceptional strength and durability. It is manufactured using high-quality hardwood or softwood veneers, which are bonded together with waterproof adhesive under high pressure. This process creates a strong and stable panel that can withstand harsh marine environments.

-

Moisture resistance

This plywood is designed to resist moisture and prevent fungal growth. It is treated with special chemicals that make it resistant to water, salt, and other marine elements. This makes it an ideal choice for applications where exposure to moisture is inevitable.

-

Lightweight

Laminated marine plywood is relatively lightweight compared to other types of marine-grade plywood. This makes it an excellent choice for boat builders and other marine applications where weight is a critical factor. Its lightweight nature does not compromise its strength and durability.

-

Flexibility

Laminated marine plywood is highly flexible. This allows it to be used in applications that require curved or irregular shapes. Its flexibility makes it an ideal choice for boat hulls, decks, and other areas requiring a smooth, streamlined surface.

-

Easy to work with

This plywood can be easily cut, shaped, and drilled to suit specific project needs. It holds screws and nails well, and its surface can be easily sanded and finished. This makes it a popular choice among boat builders and woodworkers.

-

Cost-effective

Laminated marine plywood is a cost-effective solution for marine applications. Its durability and strength mean it can last many years, providing excellent value for money.

-

Versatility

Laminated marine plywood is a versatile material that can be used in various marine and non-marine applications. It is used in boat building, furniture construction, flooring, wall paneling, and more.

-

Aesthetic appeal

Laminated marine plywood has an attractive appearance due to its natural wood grain. It can be stained or painted to match any design style or preference.

Scenarios of Laminated Marine Plywood

Laminated marine plywood is a versatile material used in various applications where durability, strength, and resistance to moisture are essential. Here are some common usage scenarios:

-

Boats and Marine Vessels

Laminated marine plywood is extensively used in boat construction and repair. It is employed for hulls, decks, cabins, bulkheads, and interior fittings. Its waterproof properties, strength, and stability make it suitable for withstanding harsh marine conditions.

-

Docks and Jetties

It is used in the construction of docks, piers, and jetties. The plywood can withstand constant exposure to water and humidity, making it ideal for areas with high moisture levels.

-

Yachts and Sailboats

Laminated marine plywood is commonly found in yachts and sailboats. It is used in the construction of hulls, decks, and interior spaces due to its lightweight and strong characteristics.

-

Cabins and Cottages

These cabins and cottages are built near lakes or coastal areas using laminated marine-grade plywood for walls, roofs, and floors. Its resistance to moisture makes it a suitable choice for these structures.

-

Outdoor Furniture

Laminated marine plywood is used in outdoor furniture such as benches, picnic tables, and storage boxes. Its durability and resistance to moisture help ensure a longer lifespan of the furniture.

-

Trailer and Camper Construction

This plywood is often used in constructing trailers and campers. Its lightweight nature and strength are crucial for towing vehicles and providing a stable living space.

-

Architectural Elements

Laminated marine plywood is sometimes used in architectural elements such as awnings, pergolas, and trellises. Its ability to resist moisture and structural integrity makes it appropriate for these applications.

-

Flooring

In certain cases, laminated marine plywood can be used as a subflooring material in areas prone to moisture, such as kitchens, bathrooms, and laundry rooms. Its stability and strength provide a good foundation for flooring materials.

-

Storage Sheds and Garages

It can be used to build storage sheds and garages in areas with high humidity or frequent rain. Its waterproof properties help protect stored items from moisture.

How to Choose Laminated Marine Plywood

When deciding on laminated marine plywood, consider the following factors:

-

Think About the Purpose

Identify the intended use and application for laminated marine plywood. Consider exposure to moisture, marine environments, structural requirements, and specific project demands.

-

Quality Evaluation

Choose laminated marine plywood with excellent quality. Check the number of layers in the plywood and the bonding strength to ensure it's durable and robust. Look for a smooth surface finish, which is vital for the final product.

-

Thickness and Size

Select the appropriate thickness and size of laminated marine plywood based on the intended application and construction requirements. Ensure it fits within the budget and available space.

-

Evaluate the Cost

While seeking affordability, prioritize quality to guarantee long-term satisfaction. Consider the plywood's lifespan, potential repair costs, and replacement to make an informed decision.

-

Environmental Considerations

Choose laminated marine plywood manufactured with eco-friendly adhesives and sustainable practices. This minimizes environmental impact and promotes responsible forestry.

-

Consultation and Expert Advice

Seek guidance from industry experts, suppliers, or professionals with experience in selecting laminated marine plywood. Their knowledge and expertise can provide priceless insights and assist in making informed decisions.

-

Availability and Lead Time

Consider the availability of laminated marine plywood and the lead time required for procurement. This is important for projects with strict timelines and requires efficient planning and execution.

-

Evaluate Additional Features

Assess any additional features or specifications of laminated marine plywood, such as fire resistance, anti-slip surfaces, or treatment against pests. These elements can enhance the plywood's performance and suitability for particular applications.

Laminated Marine Plywood Q&A

Q1: What is the difference between marine-grade plywood and laminated marine plywood?

A1: Marine-grade plywood is not necessarily waterproof but uses a waterproof adhesive to bond the veneer layers. On the other hand, laminated marine plywood has a laminate layer on the surface, making it waterproof and adding other desirable qualities like anti-slip, flame resistance, etc.

Q2: What are the disadvantages of laminated marine plywood?

A2: Laminated marine plywood has very few disadvantages. It may not be as aesthetically pleasing as plain marine plywood because of the laminate layer. It is also slightly more expensive due to the additional processing and materials. However, the advantages far outweigh the disadvantages.

Q3: How long can laminated marine plywood last?

A3: With proper care and maintenance, laminated marine plywood can last decades. This includes proper sealing and finishing to prevent water from penetrating the edges and untreated surfaces. It is also important to use proper fixing techniques to avoid damaging the plywood.