light density fiberboard

light density fiberboard

light density fiberboard

light density fiberboard

light density fiberboard

light density fiberboard

light density fiberboard

light density fiberboard

light density fiberboard

light density fiberboard

light density fiberboard

light density fiberboard

light density fiberboard

light density fiberboard

light density fiberboard

light density fiberboard

light density fiberboard

light density fiberboard

light density fiberboard

light density fiberboard

light density fiberboard

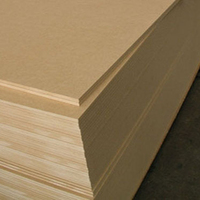

Introduction to Light Density Fiberboard

Light Density Fiberboard, commonly known as LDF, is an engineered wood product made from wood fibers combined with resin under heat and pressure. This versatile material is widely recognized for its lightweight nature, making it an excellent choice for various applications in construction and furniture. With its smooth surface and excellent machinability, LDF provides a reliable and durable alternative to traditional solid wood.

Types of Light Density Fiberboard

The market offers several types of Light Density Fiberboard tailored to meet diverse needs. Here are the most common varieties:

- Standard Light Density Fiberboard: This is the most basic form, ideal for general use in indoor furniture and applications where weight and ease of handling are key considerations.

- Moisture-Resistant LDF: This variant is treated to resist moisture, making it suitable for areas prone to humidity, such as kitchens and bathrooms.

- Fire-Retardant LDF: Specifically designed for added safety, this type helps reduce fire risks in buildings and is often used in commercial settings.

- Decorative LDF: This version comes in a variety of finishes and colors, ideal for aesthetic applications in cabinetry and interior design.

Applications of Light Density Fiberboard

Light Density Fiberboard is a favorite choice across many industries, thanks to its exceptional properties. Here are some common applications:

- Furniture Manufacturing: LDF is extensively used in making lightweight furniture pieces like wardrobe interiors, shelves, and decorative panels.

- Interior Construction: In building projects, LDF serves as wall paneling, ceiling tiles, and cabinets due to its ease of installation and versatility.

- Soundproofing: With its sound-absorbing qualities, LDF is perfect for creating sound barriers in music studios and educational institutions.

- Packaging Materials: Its lightweight nature and durability make it an excellent choice for packaging fragile items.

Features and Advantages of Light Density Fiberboard

The numerous features of Light Density Fiberboard contribute significantly to its popularity. Here are some of the key features and advantages:

- Lightweight Composition: Its low density allows for easy handling and transportation, reducing shipping costs significantly.

- Smooth Surface: The fine texture ensures excellent paint and finish adhesion, achieving a professional appearance.

- Eco-Friendly Option: Made from recycled wood fibers, LDF is a sustainable choice that reduces deforestation.

- Affordable and Cost-Effective: Typically more budget-friendly than solid wood products, LDF offers a value-driven solution for various projects.

- Versatile Applications: It can be easily cut, shaped, and laminated, catering to a wide array of furniture and construction needs.