lpg compressor

lpg compressor

lpg compressor

lpg compressor

lpg compressor

lpg compressor

lpg compressor

lpg compressor

lpg compressor

lpg compressor

lpg compressor

lpg compressor

lpg compressor

lpg compressor

lpg compressor

lpg compressor

lpg compressor

lpg compressor

Types of LPG compressors

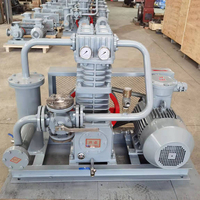

LPG compressors are mechanical devices designed to increase the pressure of liquefied petroleum gas. In the machinery industry, there are different types of lpg gas compressors based on design, technology, and application.

-

Reciprocating LPG Compressor:

The reciprocating LPG compressor is a positive-displacement compressor. The type of compressor uses a piston to compress gas through the processes of suction, compression, and discharge. Available in single-stage and multi-stage models, the latter is more common for handling high-pressure requirements. Multi-staging provides a higher outlet pressure by allowing the gas to be recompressed several times within the device. Overall, the design of the reciprocating compressor is simple and effective. As such, it has been widely used to handle gas with medium and high levels of pressure. The compressor works best for small to medium sizes of businesses that use LPG as their main source of energy for production.

-

Screw LPG Compressor:

The screw LPG compressor is designed to have two rotating screws that increase the pressure of the gas by trapping and compressing it. The construction of the compressor allows for continuous flow, high efficiency, and low levels of noise during operation. Based on these features, the compressor handles high-capacity demands very well. It is mostly used in larger-sized businesses. Those that have a need to store or transport large amounts of LPG.

-

Scroll LPG Compressor:

The scroll LPG compressor has two spiral-shaped disks (also called scrolls) as its main mechanism for compressing gas. One of the disks is fixed while the other orbits around it. This creates small pockets between the two where the gas is drawn in and compressed. The design of the scroll compressor allows for a more efficient process of compression and reduced levels of noise and vibration. Because of this, the scroll compressor is more suitable for handling medium to high-caliber businesses. Those that require a constant and steady supply of LPG as their energy source.

Specification and Maintenance of LPG Compressors

Specification

Specifications for LPG gas compressors differ for each model depending on the application. Generally, the following specifications apply.

-

Displacement

Displacement refers to the quantity of gas a compressor can move at any given time. It is usually expressed in liters per 100 revolutions. The displacement will depend on the compressor's physical size and the revolutions it makes in a minute.

-

Power Rating

The amount of energy a compressor needs is expressed in horsepower (HP). It also indicates the size of the compressor. A higher power rating means more energy use.

-

Operating Pressure

Operating pressure is the gas pressure a compressor can handle. It's usually stated in bar (1 bar = 14.5 pounds per square inch). Commercial compressors have a range of operating pressures. The actual operating pressure will depend on the application and how the machine is designed.

-

Motor/Driver

Typically, LPG gas compressors use AC motors between 60kW and 150kW. Some special configurations may use different power motors. Some compressors may have a diesel motor, depending on the energy source.

Maintenance

For compressors to function properly over time, maintenance is essential. Gas compressors are expensive, so regular maintenance helps protect the equipment, steady production, and save energy costs.

Instruction manuals provide maintenance schedules for each type of compressor manufactured. Follow the maintenance procedures as per the manual. In general, the following maintenance tips apply:

- Do a visual examination before starting work each day. Check for any sign of leakage, loose parts, or damage.

- Ensure parts that require lubrication are well-oiled.

- Check the gas/air intake filter regularly and clean or change it as required.

- Maintain equipment logs and record any maintenance and repairs done.

- Warranty claims benefit from detailed maintenance logs, so it's critical to keep records.

- Consider an extended warranty to improve cost-effectiveness and reinforce equipment protection.

Scenarios of LPG compressors

-

Natural gas gathering and processing:

At rural gas wells, an LPG gas compressor may gather natural gas from multiple wells into one pipeline. In gas processing plants, LPG compressors can separate valuable components like ethane, propane, and butane from natural gas for sale or further use in chemical manufacturing.

-

Transporting propylene in petrochemical facilities:

Some petrochemical facilities convert raw materials into products like polypropylene that are essential for making many plastic items. These facilities frequently utilize LPG compressors to effectively and economically transport propylene through pipelines to different sections of the facility or to storage.

-

Storing LP gas in tanks:

When liquefied petroleum gas (LPG) is not in immediate demand, it can be stored in large tanks. LPG can be stored as gas or liquid form, but utilizing an LPG compressor to convert the gas into liquid makes storage more efficient.

-

Loading LPG onto ships:

Compressor-driven liquefied petroleum gas (LPG) can be efficiently and safely loaded onto various types of ships using pipelines equipped with compressors. This method proves advantageous for maritime transportation, whether it be for the export of LPG or the import of LPG through overseas suppliers.

How to Choose LPG Compressors

The following tips focus mainly on helping business buyers select compressors of all kinds:

-

Usage Analysis

It will be helpful to think about the application before selecting an LPG compressor. Identify the features and specifications needed for the intended use. For example, a construction business buyer may need a high flow rate at a high pressure for the machine to perform well at remote locations. Such a buyer should aim to select a compressor with a powerful engine. Consider factors like space, weight, suitable fuel, and the machine's operating environment.

-

Quality and Durability

Get an LPG compressor from a manufacturer that uses quality, durable materials. Check for solid build quality and reliable craftsmanship. Some compressors will stake their durability on constant, faultless functionality. Select one that suits the business's use when a warranty comes attached.

-

Energy Efficiency

Consider the running and maintenance expenses of using the compressor. Choose an energy-efficient LPG model to cut fuel costs. A compressor with an efficient engine will go a long way toward reducing carbon footprint.

-

Service and Support

Select a compressor from a manufacturer or supplier that offers good product support. Consider the availability of spare parts and technical support. It makes sense to choose a compressor that many service outlets can attend to close by. When the spare parts are easily available and the technicians know the job well, the downtime will be very low during maintenance.

-

User Reviews

User Reviews will offer some idea of what to expect from an LPG compressor. Read about the experiences of other buyers and end-users. This exercise in research can help reveal insights into the compressor's performance, durability, and support services.

Q&A

Q1: How does an LPG compressor differ from a natural gas compressor?

A1: Natural gas is comprised mostly methane, which has a low molecular weight. Compressing low molecular-weight gases requires less energy. Natural gas compressor systems frequently employ rotary screw compressors because they are more energy-efficient for compressing low-molecular-weight gases. The primary chemical component of LPG is butane, which has a higher molecular weight than natural gas. Due to their higher molecular weight, rotary piston compressors are better suited for gas like LPG.

Q2: What are some features of the LPG compressor?

A2: Modern LPG compressors have a wide range of features. They might, for instance, have gas-tight packing and mechanical seals that are suitable for transporting liquefied petroleum gas (LPG). To lessen noise and vibration pollution, the compressors are also designed to allow for a low-noise operation. Additionally, there are options for remote monitoring, such as the ability to remotely monitor the compressor's working status, location, fault, and alarm information, among other things. Users can perform real-time monitoring and analysis of the equipment through remote cloud platforms, realize equipment digitalization and intelligence, and facilitate equipment maintenance and management.

Q3: Does the LPG compressor market have growth potential?

A3: The market for LPG compressors is increasing as demand for LPG keeps rising. The primary markets for compressors include oil and gas, chemicals, power generation, manufacturing, and marine industries. The sectors that generate the demand for compressors are those. LPG usage in these industries has led to a rise in the need for compressors. The market for compressors is being driven by technological advancements and rising environmental awareness that encourage the use of clean fuels.