manual credit card embosser

manual credit card embosser

manual credit card embosser

manual credit card embosser

manual credit card embosser

manual credit card embosser

manual credit card embosser

manual credit card embosser

manual credit card embosser

manual credit card embosser

manual credit card embosser

manual credit card embosser

manual credit card embosser

manual credit card embosser

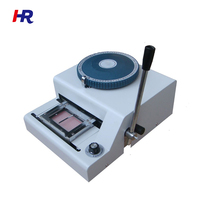

TJ-1E Small Manual Newest Design Tipper Embosser Hot Foil Stamping Machine for Paper PVC Credit Card

manual credit card embosser

manual credit card embosser

manual credit card embosser

manual credit card embosser

manual credit card embosser

manual credit card embosser

manual credit card embosser

Types of Manual Credit Card Embossers

A manual credit card embosser is a portable metal card embosser operated entirely by hand without electricity or batteries. Manual credit card embossers that are handheld allow the user to position the card within the device and apply pressure to the handle to raise the numbers and letters on the credit card. Some manual embossers are floor standing, meaning that they are tall enough to stand on the floor, and the operator must hold the metal card in place on the filling table while pulling the handle with both hands. Another way to categorize a manual credit card embosser is whether it has any additional features, like the addition of a stamp, foil or any combination of features.

- Foil stamping Manual credit card embosser: This type of manual credit card embosser adds color to the raised characters of the credit card using the technique of heat transfer. In foil stamping, embossing is used to make a design, and a particular type of stamped foil is used to fill the design. This can add glamour to an otherwise standard-issue credit card or make the information easier to notice or read.

- Combination manual credit card embosser and debosser: A manual debosser is an engraved type of card maker that carves out rather than raises letters and numbers. While both may be considered alternatives to each other, the debosser creates a less visually striking number and letter pattern by making a reverse image, which can be filled in with paint or left empty. A manual credit card embosser can sometimes be both a debosser and an embosser. This is called a combination debosser and embosser. Using the combination credit card embosser and debosser allows for greater customization of the card.

- Stamp manual credit card embosser: A manual stamp credit card embosser uses ink and a stamp rather than raising letters and numbers as an embossing machine would. An advantage of this type of manual credit card embosser is that the stamping can be done in color, and multiple copies can be made quickly and efficiently - particularly if a self-inking stamp is used.

- Handheld/portable manual credit card embosser: This type of embosser can easily be transported from one place to another. The device typically weighs very little so that it can be operated with one hand and is small enough that it does not take up very much space.

Specifications & Maintenance

The following specifications are essential when considering a suitable manual credit card embosser.

-

Size/Cards

The size of the embosser is essential. It needs to be small enough to fit in any area of the business that it will be used. They are typically desk or counter models. Most manual embossers will take the standard credit card size of 3.375 x 2.125 inches.

-

Weight

Heavy-duty manual embossers weigh approximately five to ten pounds. Smaller models may weigh less. Some have a carrying handle so that they can be transported to different locations, such as sales and marketing events.

-

Operating Mode

These embossers are mechanically operated. The operator pushes a handle down or pulls a lever to make the card with raised numbers and letters. Some manually operated devices may include a spring-loaded mechanism.

-

Durability

The construction needs to be strong enough for frequent use. Heavy-duty metal embossing machines are more durable than plastic models. They will have a metal casting body, a die holder, and an embossing mechanism.

Maintenance

To keep the embosser card maker in operating condition, it will need cleaning and occasional lubrication. Care of the device will improve its performance and longevity.

-

Clean the machine:

Remove any card debris after embossing. This is usually from the plastic coating of the credit card. Clean the surfaces with a soft brush or vacuum cleaner attachment. Clean the die with warm, soapy water and a soft cloth. Dry it thoroughly before refitting it into the machine to avoid rusting.

-

Lubricate the moving parts:

After cleaning, apply a small amount of lubricant to the moving parts and pivot points of the machine. Use lubricant oil with a spray nozzle for hard-to-reach areas. Occasionally, the gears may require a small amount of lubrication for more significant mechanical parts.

-

Wipe with a cloth:

Use a lint-free cloth for cleaning and lubricating. This will ensure that no remnants are left on the parts of the machine that may cause damage.

-

Avoid using lubricants on plastic parts:

Scenarios of using manual credit card embossers

Apart from the above uses in making identifications and for business purposes, there are other increased uses of credit card embossers.

- A credit card manual embosser can be used by the police or any law enforcement agency to make a record of a person's arrest at the time of arrest. This record can be immediately presented to the Police Department of the city for proper follow-up and handling of the case without delay.

- The medical sector uses credit card embossers to create medical or health-related documents and cards for patients, which indicates their medical history, prescription, or any required information. This card can, therefore, be used to ensure proper and timely medication.

- Embossers are also used in the logistics industry to mark or customize packaging materials, shipping crates, or products with logos, barcodes, tracking numbers, or other relevant information. This enhances brand visibility, facilitates packaging, and improves supply chain management.

- The sports industry uses credit card embossers to produce tickets, season passes, or membership cards for fans, players, or club members. These cards can, therefore, be used to ensure proper and timely entry into the stadium or sporting facility, thereby enhancing customer satisfaction.

How to choose a manual credit card embosser

There are a number of factors to take into account when selecting the appropriate manual credit card embosser for a business's unique needs.

-

Business requirements analysis:

-

Practicality and user experience:

To start, it is crucial to determine the business's needs thoroughly. The kinds of cards should be considered first. Will the cards that need to be embossed be plastic, paper, or other materials? For instance, businesses that primarily deal with plastic cards, such as those made of PVC, will require an embosser that can process these materials without causing any damage to them.

Secondly, consider the card's size and shape. Standard-sized credit cards have specific dimensions, but other cards, like membership or discount cards, may have different sizes or even be custom-shaped. Thirdly, think about the information that needs to be embossed on the card. Complexity and quantity are also important considerations here. Some businesses may only need to include a name and number, while others may need to emboss multiple lines of text. This factor directly influences the choice of embosser model.

Thirdly, consider the necessary embossing quality and grade. Some businesses require high-precision embossing for better readability and aesthetics, which may involve distinct embossers.

Finally, estimate the daily or monthly card volume that needs to be embossed. Some models can handle a higher volume without performance degradation, which is essential for busy businesses.

Consider the operation mode of the card embosser. Manual credit card embossers are affordable and easy to use; however, manual operation can be slow. Semi-automatic embossers offer a balance between cost and efficiency. By pressing the embossing button, the operator can stamp cards with a simple pull of the lever. This model requires manual card placement and lever pulling. Another option is fully automatic embossers, which automate the entire process. The operator only needs to place the card into the machine's slot, and with the push of a button, the machine will emboss the card automatically. Fully automatic models are more expensive but are ideal for businesses with high card production needs.

Consider the size and weight of the embosser, as well as whether it needs to be stationary or can be moved around. If it needs to be moved, the embosser should be light and small enough to carry and have a sturdy construction so that it can be used as an inline one.

Another consideration is the embossing speed. Different models have different speeds, which may affect production efficiency.

Connection options for some models are also worth considering. It is possible to connect the device to a computer or tablet, input the information that needs to be embossed onto the card, and print it directly onto the card.

Q&A

Q1: Why are embosser cards used?

A1: Embosser cards are used for various purposes such as increasing the security of a card, making it visually appealing or enabling the card to be used with manual machines.

Q2: What does a credit card embosser do?

A2: A credit card embosser is a machine that either raises or lowers letters, numbers or symbols on a plastic card. The raised letters can be read by sight or touched.

Q3: What are the types of credit card embossers?

A3: Credit card embossers can be divided into automatic and manual types. The manual credit card embosser is operated by hands and is suitable for small businesses. On the contrary, automatic ones are good for high-volume productions.

Q4: Is credit card embossing illegal?

A4: It is not illegal to emboss a personal credit card. Nevertheless, it is illegal to use an embosser to create a credit card or any other thing with the intent to defraud.