metal grinder

metal grinder

metal grinder

metal grinder

metal grinder

metal grinder

metal grinder

metal grinder

metal grinder

metal grinder

metal grinder

metal grinder

metal grinder

metal grinder

metal grinder

metal grinder

metal grinder

metal grinder

metal grinder

metal grinder

metal grinder

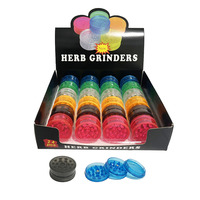

Types of metal grinders

A metal grinder is a powerful tool for grinding metals and other materials. There are several different types of metal grinders, each designed for a specific purpose. They are as follows:

-

Bowl grinder

This kind of grinder has a bowl-shaped grinding element. It is ideal for processing hard, brittle samples. It grinds samples into fine powders. This is useful in mineralogy, forensics, and geology.

-

Angle grinder

This is a handheld power tool. It is also called a side grinder or angle power tool. It has a rotating shaft at an angle to the handle. It is commonly used to grind, polish, cut, and sharpen metals and other materials. It is widely used in construction and manufacturing.

-

Bench grinder

This is a power tool with two wheels mounted on a bench. Each wheel has a different grit for rough and fine grinding. It is used to sharpen, shape, and polish metal tools and parts.

-

Die grinder

This is a handheld tool for precise grinding. It has a rotating spindle. It is used to grind small parts and tight spaces. It is used to smooth welds, shape parts, and clean molds.

-

Cylindrical grinder

This is a machine tool for grinding cylindrical shapes. It has a rotating workpiece and a stationary grinding wheel. It is used to make precision shafts, pins, and rods.

-

Surface grinder

This is a machine tool for grinding flat surfaces. It has a reciprocating table and a vertical spindle. It is used to make precision plates, blocks, and fixtures.

-

Wet/dry vacuum metal grinder

This is a vacuum cleaner with a grinding feature. It collects both dry dust and wet sludge. It is used to clean metal shavings and coolant from machining operations.

Design of metal grinders

-

Four-piece grinder:

A four-piece grinder consists of four chambers. The first compartment contains sharp teeth that shred the herbs. The second one has a mesh screen that sifts the fine particles. The last chamber collects the dust-like ground herbs. This design allows users to get both coarse and fine textures. It also prevents residue buildup in the grinder. An example of a four-piece metal herb grinder is the Cali Crusher.

-

Diamond-shaped teeth grinder:

As the name suggests, this grinder has teeth shaped like diamonds. It usually comes in four pieces. The mesh screen separates fine particles, and the last chamber collects them. This design gives a consistent and even grind. It works well for both coarse and fine textures. An example of this grinder is the Mendo Mulcher.

-

Single chamber cylindrical grinder:

This metal herb grinder has only one chamber. It is cylindrical and has sharp teeth at the bottom. The user puts in the herbs and then turns the lid to grind them. This simple and compact design is easy to use. However, it does not separate fine particles or provide different texture options. An example is the Zip Grinders.

-

Polyhedral grinder:

This grinder has a unique geometric design with multiple faces. It usually comes in three pieces. The grinding action occurs at the corners of the polyhedral shapes. This design gives a consistent grind. An example of this type of grinder is the Chromium Crusher.

Scenarios of metal grinders

These are two scenarios where a metal grinder is a necessary tool.

-

Construction site:

A metal grinder is a common tool on construction sites. They use it to shape and polish metal components. It helps adjust metal parts for structures like buildings, bridges, and roads. Workers use it to make a clean cut on rebar, pipes, and sheets. It removes welding beads and sharp edges from hand tools and equipment. Grinders are also used to make metal parts fit together. They are essential for making metal parts for large projects. They ensure that the metal pieces fit together exactly.

-

Manufacturing facility:

Manufacturing facilities also use metal grinders. Factories that make metal parts use them to shape and finish metal. For example, a factory that makes car parts or machines might use a grinder to shape metal into the right form. Factories also use special grinders to grind metal powders. These powders can be used to make new metal parts or to coat surfaces. The grinder helps make the metal powders even and smooth. This is important for making parts that work well. In a factory, metal grinders help make metal parts that are used in many products that people use every day.

How to choose a metal grinder

-

Materials

Knowing what the food metal grinders will grind is essential. If the primary purpose of the grinder is to grind meat, then a metal grinder with stainless steel materials is ideal. However, if the plan is to grind spices, a cast iron grinder will be a better option.

-

Space

Some metal grinders, like the old-fashioned ones, require more space. If there's no sufficient space, consider an electric grinder that can be easily stored after use.

-

Budget

Manual metal grinders are inexpensive, but electric grinders come with many features and are more expensive. Determine the budget before purchasing.

-

Function

Determine whether to use the metal grinder for the intended purpose. Some grinders come with additional features that allow users to use them for various purposes.

-

Quality

Always look for the product quality before buying. Reliable brands often make them with solid, durable materials.

-

Efficiency

Ensure to check the efficiency of the metal grinder before buying it. Read reviews and ask questions to determine its efficiency.

-

Safety features

For electric grinders, check if there are safety features like a circuit breaker. For manual grinders, ensure there are safety blades to prevent accidents.

-

Warranty and support

Opt for a metal grinder that offers warranty and customer support. It helps to address any issues that may arise after purchase.

Q&A

Q1. What is a metal grinder used for?

A1. A metal grinder is used to break down metals into smaller pieces for recycling or further processing.

Q2. What are the benefits of using a metal grinder?

A2. The benefits include improving material recycling efficiency, reducing storage space for unprocessed metals, and enabling the reuse of metals for different applications.

Q3. What types of metals can be ground using a metal grinder?

A3. Metal grinders can grind various metals, including hard and soft, such as aluminum, steel, brass, iron, and copper.

Q4. How can users ensure the grinder's longevity?

A4. Users can maintain their metal grinder by regularly cleaning the device, periodically lubricating its parts, and checking for any signs of wear and tear.

Q5. What safety measures should be taken while using a metal grinder?

A5. Users should wear protective gear like gloves and goggles, ensure proper equipment grounding, and avoid loose clothing that could get caught in the grinding wheel.

Popularity Trends

The web search volume for the keyword "metal grinder" in the homegarden category has shown a consistent average monthly web search volume of 2900, with no significant change over the past year or three months. The data reveals minor fluctuations within individual months, but the overall trend remains stable.

Over the past twelve months, the web search volume for "metal grinder" peaked at 2900 web searches several times, notably in November 2023, March 2024, and continuously from April to October 2024. Conversely, the volume dipped to 2400 web searches during the December 2023 to February 2024 period. This pattern suggests a slight seasonal variation, with higher interest in the warmer months and a minor decline during the colder months.

Despite these minor dips and peaks, the keyword has maintained a steady overall interest level, as indicated by the consistent average and lack of significant year-over-year or quarter-over-quarter changes. This stability could be attributed to the ongoing, consistent demand for metal grinders in homegarden applications, without any notable external influences causing substantial shifts in search behavior.