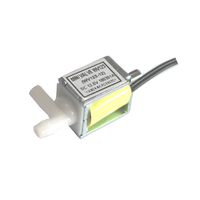

micro solenoid valve

micro solenoid valve

micro solenoid valve

micro solenoid valve

micro solenoid valve

micro solenoid valve

micro solenoid valve

micro solenoid valve

micro solenoid valve

micro solenoid valve

micro solenoid valve

micro solenoid valve

micro solenoid valve

micro solenoid valve

micro solenoid valve

micro solenoid valve

micro solenoid valve

micro solenoid valve

micro solenoid valve

micro solenoid valve

micro solenoid valve

Types of micro solenoid valves

A micro solenoid valve is a small-sized solenoid valve that uses electrical energy to control the flow of gas or liquid. They come in different types to fit various industrial applications.

-

Direct-Acting Micro Solenoid Valves

Direct-acting micro solenoid valves are small valves that open directly when an electrical current is applied. They are small and typically open against a spring force to allow fluid flow. After the electric current is removed, the spring rushes back to its original position and closes the valve. These types of micro solenoid valves are commonly used in small devices like toy water guns, coffee machines, and air fresheners.

-

Selective Micro Solenoid Valves

Unlike direct-acting micro solenoid valves, which only open one way, selective micro solenoid valves can let fluid flow in or out through different ports. They achieve this by using electromagnetic forces to move internal parts. Selective micro solenoid valves are found in more advanced gadgets where controlling the direction of fluid is important, like in medical equipment for precise medicine delivery.

-

Normally Closed Micro Solenoid Valves

Normally closed (NC) micro solenoid valves have no fluid movement when the valve is off. When an electric current is connected to the coil, it generates a magnetic force that moves the plunger upward, allowing gas or liquid to flow. Other applications of this valve type include water dispensers, cooling systems, and inkjet printers.

-

Normally Open Micro Solenoid Valves

Normally open (NO) micro solenoid valves allow fluid to flow freely when not energized. When electric current is provided to the valve, it closes off the flow path. Normally open micro solenoid valves are used in air control applications, fuel delivery systems, and pneumatic tools.

Specifications and Maintenance

Micro solenoid valves have several specifications that buyers should note when purchasing or using them. The material used to make the valve is a crucial specification. Manufacturers produce micro solenoid valves using materials like stainless steel, brass, nylon, and PVDF. These materials are strong and can withstand constant usage for a long time without breaking. Also, the materials are compatible with various liquids. Another specification to consider is the valve's pressure rating. The micro solenoid valve's pressure rating determines the maximum pressure the valve can handle. The pressure rating is critical for flow control applications because it affects valve performance. Micro solenoid valve manufacturers produce valves with various pressure ratings. Buyers should get the valves with pressure ratings that suit their applications. Valve orifice size is another specification to consider. Micro solenoid valves have orifice sizes ranging from 0.2mm to 6mm. The orifice size affects the flow rate. In general, the flow rate of the liquid increases as the orifice size increases.

Micro solenoid valves need maintenance to keep working well and to extend their lifespan. Cleaning the valve parts comes first in the maintenance process. This gets rid of debris, dirt, or deposits that build up on the valve parts over time. Cleaning will improve the valve performance and prevent clogs. After cleaning, ensure the parts are dry before putting them together. For long-lasting service, micro solenoid valves need lubrication from time to time. Lubricating the moving parts of the valve allows for smooth and effortless operation. It also reduces wear and tear. Users should apply a small amount of lubricant to the valve's moving parts. Regular inspection is also important in maintaining micro solenoid valves. Inspect the valves for damage signs like leaks, cracks, or misalignments. Once there are damage signs, get the valve repairs done right away to prevent further issues and to prolong valve life. Buyers can also ask professional services to carry out maintenance on the valves periodically.

Applications of Micro Solenoid Valves

A solenoid valve regulates the flow of liquids and gases in different industries. The micro solenoid valve is smaller in size but performs the same function even in limited spaces. Here are some common applications of micro solenoid valves in various fields.

- Medical Equipment: Micro solenoid valves control the precise flow of gases and liquids in medical devices, such as oxygen flow meters, ventilators, anesthetic machines, CPAP machines, nebulizers, IV infusion pumps, and drug delivery systems. The accurate flow regulation ensures safe and effective patient care and treatment.

- Automotive Industry: Micro solenoid valves are widely used in automotive applications, such as fuel injection systems, tire pressure monitoring systems, and cooling system controls. For example, in fuel injector control, these valves help regulate the precise amount of fuel delivered to the engine for efficient combustion and vehicle performance. Their small size allows easy integration into space-constrained automotive designs.

- Home Appliances: Micro solenoid valves are found in various home appliances, including coffee machines, dishwashers, humidifiers, washing machines, refrigerators, and air conditioners. For example, in coffee machines, these valves control the water flow used for brewing. The compact size enables appliance manufacturers to include them in designs that save energy and space.

- Robotics and Automation: Micro solenoid valves play a crucial role in pneumatic control systems used for robotics and automation. These valves precisely control the airflow to pneumatic actuators and cylinders, which are responsible for movement. Solenoid valves are essential components that enable automation systems to function with high precision.

- Aerospace Applications: Micro solenoid valves manage the flow of fuel and oxidizers in rocket engines and control air intake and exhaust in aircraft engines. Size and weight are crucial for aerospace applications, so engineers look for compact solutions that are effective and reliable.

- Laboratory Equipment: Micro solenoid valves are small yet powerful devices that allow scientists to conduct their research precisely and reliably. They control liquids in pipetting systems, chromatography, mass spectrometry, and chemical reaction injection. Their compact size enables seamless integration into the fluidic systems of analytical instruments.

How to choose a micro solenoid valve

Business buyers need to consider several important factors when selecting micro solenoid valves. Here are ways to pick:

-

Application requirements analysis:

Users should analyze the specific use needs of the application, such as the fluid medium, pressure range, flow rate, operating temperature, voltage, and current of the micro solenoid valve. Match the requirements to ensure that the selected valve can adapt and function normally to the specified conditions.

-

Quality and reliability:

Users should choose a supplier with an excellent reputation and reliable product quality. Check the valve's design and manufacturing techniques, including the material selection, manufacturing process, and quality control during production. Consider the valve's service life, reliability, and maintainability to ensure long-term stable operation in the application.

-

Supplier selection:

Choose a reputable and reliable supplier. Research and compare different suppliers' product ranges, quality levels, technical support, and after-sales service. Consider the supplier's industry experience and customer evaluation to ensure that users can obtain excellent products and services.

-

Installation and connection:

Check the installation dimensions and connection methods of the micro solenoid valve to ensure that it can be correctly installed and connected in the application system. Pay attention to the matching of pipe sizes and connection standards to avoid installation errors or leaks.

-

Cost-performance ratio:

Users should comprehensively consider the performance, quality, and price of the micro solenoid valve to select a product with an excellent cost-performance ratio. It is also important to ensure that the chosen valve can meet the application's needs and avoid excessive or inadequate configuration.

Q&A

Q1: How does a micro solenoid valve work?

A1: A micro solenoid valve works by producing linear movement. The micro solenoid valve consists of a coil, plunger, return spring, and housing. The coil receives electrical current flow, creating an electromagnetic field that draws or pushes the plunger. The valve's opening and closing are controlled by the plunger movement. The return spring goes back to its original position when the electric current is off, and the valve is closed.

Q2: What are the advantages of micro solenoid valves?

A2: The micro solenoid valves have several benefits. They are small and use less power and allow low power consumption, making them ideal for battery-powered applications. The micro solenoid valve provides precise control of fluid or gas flow. Fast-response micro solenoid valves allow quick opening and closing. Micro solenoid valves are easy to integrate into automatic systems or controlled by remote.

Q3: What are the types of micro solenoid valves?

A3: There are normally open (NO) and normally closed (NC) micro solenoid valves. A normally closed micro solenoid valve is off when there is no electric current flow, and the valve is closed. Normally closed micro solenoid valves are used for gas transmission, water systems, and medical devices. A normally open micro solenoid valve is on when there is electric current, and the valve is open. Normally open micro solenoid valves are used in cooling systems and pneumatic systems.