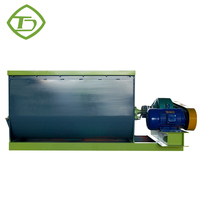

mini powder mixer

mini powder mixer

mini powder mixer

mini powder mixer

mini powder mixer

mini powder mixer

mini powder mixer

mini powder mixer

mini powder mixer

mini powder mixer

mini powder mixer

mini powder mixer

mini powder mixer

mini powder mixer

mini powder mixer

mini powder mixer

mini powder mixer

mini powder mixer

mini powder mixer

mini powder mixer

mini powder mixer

Types of mini powder mixers

As essential equipment for the machinery industry, mini powder mixers are designed to improve the homogeneity of materials. They are used to blend dry solids and liquids to form solutions, emulsions, suspensions, or mixtures with products varying in consistency and viscosity. Mini powder mixers come in many forms to cater to different requirements.

-

Laboratory mixers

Lab-scale mini powder mixers facilitate product development and testing. They enable the small-scale mixing of powders with liquids to produce samples for analysis, evaluation, or quality control. These mixers have speed variations, allowing precise adjustments to cater to different product requirements.

-

Handheld mixers

These types of mixers are small and portable. Mostly, they are powered by electric motors and have ergonomic designs for comfortable handling. Handheld mini powder mixers are used in food, beverage, and pharmaceutical applications. In food applications, for instance, they are used to prepare sauces, dressings, and beverages.

-

Mixing cups with agitators

These provide a separate mixing unit and container. The agitator is often a small motorized device with a stirring mechanism that blends the powder into the liquid. The automatic mixing cups have programmable settings that allow users to customize the mixing speed and time. This ensures consistent results every time. Some of the advanced models also have a self-cleaning function, which makes them easy to maintain and sanitize.

-

Portable powder mixers

Portable powder mixers are specifically designed for mobility, allowing mixing operations to be performed in various locations. They are compact and lightweight, making them easy to transport and handle. The mixers are suitable for industries where powder materials are processed away from fixed installation sites, such as food processing, construction, and agriculture.

-

Sachet/ container-loading mixers

These mixers are designed to accommodate and blend powder products efficiently, such as spice mixes, protein powders, and seasoning blends, into containers or sachets. They ensure precise dosing, consistent quality, and rapid processing to meet the demands of high-volume production and strict quality control.

Specification and Maintenance of Mini Powder Mixers

Mini powder mixers are available in various specifications depending on the type and model. Here are the general specs of mini powder mixers.

- Capacity: Mini powder mixers have different capacities based on their design and purpose. The capacity is measured in liters or gallons to indicate the maximum volume it can blend.

- Motor Power: The power of the motor is measured in horsepower (HP) or watts. It determines the strength of mixing to handle different types of powders.

- Speed Control: Mini powder mixers have a speed control feature and allow users to adjust the blending speed. The speed control can be in the form of knobs, buttons, or digital displays.

- Blending Tools: Mini powder mixers blend different types of powders. They might come with different blending attachments, like whisk, blade, or paddle.

- Construction Material: Mini powder mixers are manufactured using different kinds of materials. The most common are stainless steel and food-grade plastic.

- Noise Level: The noise level caused by the mixing machine is measured in decibels (dB). Mini powder mixers are compact machines. Their noise levels are low, making them suitable for use in areas that require minimal interruption.

Maintenance

When taken care of properly, mini powder mixers can serve users for a long time. Here are some maintenance tips manufacturers and suppliers can recommend to buyers.

- Regular Cleaning: After every use, it's important to clean the mixer. Employers should disassemble the parts and wash them thoroughly to avoid any residue buildup.

- Avoid Overloading: Avoid overloading the mini powder mixer beyond its capacity. Overloading can strain the motor and affect the performance of the machine.

- Lubrication: Parts of the powder mixer that need to be lubricated, like gears and bearings, should be oiled or greased. This helps facilitate smooth operation.

- Storage: Once cleaned, avoid storing the mini powder mixer in damp places. Keep it in dry areas to avoid corrosion/discoloration.

Uses of Mini Powder Mixers

Mini powder mixers are useful machines in many industries and small-scale businesses. Some of the common uses include:

-

Pharmaceutical Industry

In the pharmaceutical industry, the powder mixer helps to mix large volumes of powder for different drugs. These include tablet components, excipients, and active ingredients. The mixer guarantees dosing precision and uniformity in every medication.

-

Food and Beverage Processing

Mini powder mixers combine dry ingredients, flavors, and spices. They also enhance the texture of certain foods like instant soups and powdered sauces. The mixer is also useful in pet food products to ensure all nutrients are evenly spread.

-

Cosmetics and Personal Care

In the cosmetics industry, mini mixers blend pigments, powders, and other materials to produce face powder, foundation, and eyeshadow. The mixer ensures color uniformity, even distribution of active ingredients, and smooth textures.

-

Chemical Production

Mini powder mixers are useful in chemical production for homogenous mixing of powdery materials like pesticides, fertilizers, and additive chemicals. Using the mixer helps improve product performance and efficacy.

-

Construction and Building

In construction, mini powder mixers are useful for blending powdered materials. These include cement, additives, coatings, and adhesives. The mixer enhances the strength of the final construction material and ensures uniformity.

-

Educational and Research Laboratories

Many educational institutions and laboratories use mini powder mixers for small-scale experimental mixing. The mixer combines powdered samples and chemical compounds. It is also useful for preparing experimental formulations in research.

How to Choose Mini powder mixers

When selecting the right powder mixer, buyers must consider the following:

-

Production volume and batch size:

-

Type of powders:

-

Mixing method:

-

Space constraints:

-

Mobility needs:

-

Cost-effectiveness:

Consider how much product is needed and the size of the batches that will be mixed. Find a mixer that is the right size for mixing small, efficient batches without wasting time or resources.

Think about the characteristics of the powders to be mixed, such as particle size, density, and flowability. Choose a mini mixer that can handle the particular qualities of the powders being used. For example, certain mixers are better for sticky or non-flowing powders, while others are suited for fine powders.

Understanding the various mixing techniques offered by mini mixers will help in choosing the most suitable one. Consider the desired homogeneity level and select the mini mixer that provides the required mixing method, whether it's mixing by gravity, shear, or other means.

Evaluate the amount of space available for equipment. Select a compact-sized powder mixer that will fit comfortably in the designated area without compromising the mixing capabilities.

If the powder mixing device needs to move to other parts of the facility, consider the portability options. Choose a mini powder mixer with wheels or handles that allow for easy transportation to different working locations.

In the end, select a mini powder mixer that fulfills all required mixing needs at an affordable price. Comparing features and specifications of different models will help in choosing a mixer offering the best value for the investment.

Mini powder mixer FAQ

Q1: Is the mini powder mixer suitable for all powder products?

A1: While the mini powder mixer offers great versatility, it's essential to understand that not all powders can be effectively mixed using the device. Some powders, particularly those that are oversized or have challenging compositions, may require specialized mixing equipment.

Q2: Can the mini powder mixer be used at home?

A2: The design and scale of the mini powder mixer are primarily intended for commercial and industrial use. However, some smaller models might be suitable for light home use.

Q3: How loud is a mini powder mixer?

A3: Most mini powder mixers operate at noise levels from 70 to 90 dB. It's advisable to always wear hearing protection when operating any powder mixer.

Q4: Can the mini powder mixer be mobile?

A4: Yes, the mini powder mixer is portable. Many models have wheels for easy movement around the production facility.

Q5: How does the mini powder mixer affect product integrity?

A5: The gentle blending action of the mini powder mixer helps maintain the product's integrity. Unlike high-shear mixers, these mixers do not degrade fragile ingredients.