mono pumps

mono pumps

mono pumps

mono pumps

mono pumps

mono pumps

mono pumps

mono pumps

mono pumps

mono pumps

mono pumps

mono pumps

mono pumps

mono pumps

mono pumps

mono pumps

mono pumps

mono pumps

mono pumps

mono pumps

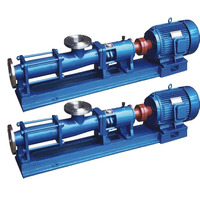

Introduction to Mono Pumps

Mono pumps, widely recognized for their innovative design and efficiency, are essential components in various industrial applications. These positive displacement pumps operate using a single, helical rotor to transfer fluids, delivering precise flow rates while maintaining low shear. Their versatility makes them a popular choice for many industries, including wastewater management, food processing, and chemical manufacturing.

Types of Mono Pumps

Mono pumps come in several types designed to meet specific operational needs. Each type boasts unique features suited for different applications:

- Standard Mono Pumps: These are designed for general pumping tasks across various industries.

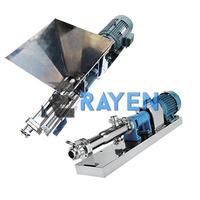

- Submersible Mono Pumps: Ideal for pumping sludge and other viscous fluids from underground sources.

- High-Pressure Mono Pumps: Built to handle high-pressure applications in the oil and gas sector.

- Food Grade Mono Pumps: Constructed from stainless steel to comply with food safety regulations.

- Chemical Mono Pumps: Made from corrosion-resistant materials to safely handle aggressive chemicals.

Applications of Mono Pumps

The applications of mono pumps are extensive and can be found in various sectors:

- Wastewater Treatment: Efficiently moves sewage and wastewater through treatment plants.

- Food and Beverage Industry: Transfers ingredients, sauces, and other viscous products without damaging them.

- Chemical Processing: Handles hazardous and corrosive fluids safely and effectively.

- Agriculture: Used for transferring slurries, chemicals, and liquid fertilizers.

- Pharmaceuticals: Ensures precise dosing and handling of sensitive liquids.

Features and Advantages of Mono Pumps

Mono pumps are distinguished by their numerous features and benefits, making them a preferred choice in many applications:

- High Efficiency: These pumps are designed to optimize flow consistency while minimizing energy consumption.

- Low Maintenance: With fewer moving parts, mono pumps require less maintenance than traditional pumps.

- Versatile Handling: Capable of pumping a wide range of fluids, including those with solid content.

- Gentle Pumping Action: The helical rotor design minimizes shear and turbulence, preserving fluid integrity.

- Compact Design: Smaller footprint allows for easy integration into existing systems.

- Durability: Made from high-quality materials, these pumps are built to withstand harsh conditions.

In summary, mono pumps stand out due to their efficient, reliable, and versatile pumping capabilities, making them indispensable in a range of industries. Whether handling wastewater, food products, or chemicals, their design and functionality cater to the diverse needs of modern applications.