oil filter element

oil filter element

oil filter element

oil filter element

oil filter element

oil filter element

oil filter element

oil filter element

oil filter element

oil filter element

oil filter element

oil filter element

oil filter element

oil filter element

oil filter element

oil filter element

oil filter element

oil filter element

oil filter element

oil filter element

Types of oil filter elements

An oil filter is made up of two primary components: the filter medium and the housing. The filter medium is the part of the oil filter that purifies the oil. The filter housing is the outer part of the oil filter that serves as a protective covering for the filter medium and allows for the connection between the oil filter and the engine.

There are several types of filter mediums, but the most popular ones are:

- Cellulose oil filter element

The cellulose oil filter element is the most popular type of filter material used in oil filters. It is made from a mixture of cotton fibers and wood pulp. Cellulose is an excellent filter material because it is highly efficient at trapping dirt and debris while allowing oil to flow freely through the filter. It is also very cost-effective, making it an ideal choice for budget-friendly oil filters.

- Synthetic oil filter element

Synthetic oil filter elements are made from man-made materials like polyester, nylon, or glass fibers. Synthetic oil filter elements are designed to offer superior filtration performance compared to cellulose filters. They are more efficient at capturing smaller particles and contaminants, which helps to keep the engine cleaner. They also have a longer lifespan than cellulose filters and can withstand higher temperatures and pressures. This makes them a popular choice for high-performance and heavy-duty engines.

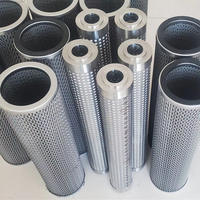

- Metal mesh oil filter element

Metal mesh oil filter elements are made from fine stainless steel or bronze wires woven into a mesh. Metal mesh filters are very durable and have a long lifespan. They are capable of trapping large debris and particles while allowing oil to flow freely, which helps to maintain proper lubrication of the engine components. Metal mesh filters are commonly used in heavy-duty and high-temperature applications, where durability and reliability are essential.

- Multilayered cellulose and synthetic blend oil filter element

Multilayered cellulose and synthetic blend oil filter elements combine the benefits of both cellulose and synthetic materials. They have a strong cellulose media layer for primary filtration and a synthetic blend for additional filtration and improved durability. This type of filter offers excellent filtration efficiency and dirt-holding capacity. It is often used in vehicles with demanding driving conditions.

- Permanent oil filter element

Permanent oil filter elements are usually made of synthetic materials or metal. They are designed to be cleaned and reused instead of being replaced at each oil change. Some permanent filter elements feature a quick-release mechanism that allows them to be removed and cleaned easily. These filters are eco-friendly options that reduce waste. However, they may require more maintenance than disposable filters.

Specifications & maintenance of oil filter elements

- Specifications

Many types of oil filter elements are available for different applications, including engine oil filter elements and fuel filter elements. The key specifications are as follows:

Media material: The filter's main material can be cellulose, synthetic fiber, or other materials. Different media have different filtration accuracies, efficiencies, and service lives.

Flow rate: The maximum flow rate of the filter element, which is measured in liters per minute or per hour, varies according to the size and design of the filter element.

Filtration rating: The filter's mesh size indicates the size of the particles it can catch. This is usually expressed in microns. The filter ratings vary from 3 microns to 200 microns, and the most common ones are 10 microns and 30 microns. The higher the filter rating, the finer the particles the filter can capture.

Compatibility: The size, connection type, and other specifications of the filter element, which must be compatible with the filter housing and the system being used.

- Maintenance

Proper maintenance is critical to the performance and longevity of the oil filter element. Below are some routine maintenance tips for the filter element.

Regular inspection: Check the appearance of the filter element for any signs of damage, such as wear, tears, or deformation. Also, check for blockages or clogging. If there is any, replace the filter element in time.

Clean the filter housing: Before replacing the filter element, clean the filter housing thoroughly. Remove any contaminants or debris to prevent them from entering the system during maintenance.

Proper installation: When installing the filter element, follow the manufacturer's instructions carefully. Ensure proper sealing and secure connection to prevent leakage and ensure optimal filtration performance.

Use the right filter element: Select a filter element that is compatible with the system and meets the specific filtration requirements. Do not use a filter element that is too small or too large for the system.

Choose a quality filter element: Choose a reliable brand of filter element and ensure its authenticity. Using high-quality filter elements can provide better filtration performance and longer service life.

Scenarios of oil filter elements

The oil filter element is used in many business scenarios that require filtration and purification of oil and other lubricants in machinery and equipment.

- Automotive Industry

The oil filter element is used in the automotive industry to purify engine oil, transmission oil, and other lubricants. The oil filter elements for cars remove impurities and particles from the lubricants, thus protecting the engine and ensuring the smooth operation of the vehicle.

- Manufacturing Industry

In the manufacturing industry, the oil filter element is used to purify the hydraulic oil and coolant used in various machinery and equipment. The oil filter elements for machinery and equipment remove impurities from the hydraulic oil and coolant, thereby preventing damage to the entire system and ensuring high-performance operation.

- Marine and Offshore Industry

In the marine and offshore industries, the oil filter element is used to purify and filter the oil used in ship engines and hydraulic systems. The oil filter elements for ships can remove water, impurities, and particles from the oil, thus preventing corrosion and wear of the engine and ensuring the safety and reliability of marine operations.

- Agriculture and Construction Industry

In the agriculture and construction industries, the oil filter element is used to purify and filter the lubricating oil used in tractors, excavators, and other heavy machinery. The oil filter elements for agricultural machinery and construction machinery remove impurities and particles from the lubricants, thereby prolonging the service life of the equipment and ensuring efficient operation in harsh environments.

Overall, the oil filter element plays a crucial role in ensuring the performance, durability, and safety of various machinery and equipment in different industries.

How to choose oil filter elements

When choosing an oil filter element, it is crucial to consider a few important factors to ensure that the filter will meet the required performance and efficiency. The first and most important thing to do is identify the specific needs of the machinery or equipment in question. Determine the type and grade of the oil that the machine uses, as this will help in selecting an oil filter element that is compatible with the oil in question.

Next, it is important to consider the type of oil filter element that is being chosen. This could be a cartridge, magnetic, or spin-on oil filter. Consider the equipment's specifications and the filter's performance requirements when selecting an appropriate oil filter element. Equipment compatibility is key when choosing an oil filter element. This means that the filter element should be the right size and shape to fit into the equipment or machinery it is being used for. Ensure that the oil filter element is the right filter for the specific equipment it is being used in.

It is important to choose an oil filter element that is manufactured with high-quality materials. Cheap parts are more likely to break, leading to equipment failure. High-quality oil filter elements will have a longer service life and be better at trapping contaminants in the oil. Consider the equipment's maintenance requirements when choosing an oil filter element. Some maintenance staff prefer to change the entire filter, while others prefer to replace the filter.

Finally, it is important to ensure that the oil filter element is sourced from a reliable and reputable supplier. This will help in ensuring the quality and authenticity of the filter. If the oil filter element is not in stock, place a bulk order with the supplier to avoid running out of stock and disappointing customers. Determine the payment method and the supplier's delivery timelines to ensure a smooth transaction. Some suppliers may offer discounts on bulk orders, so it is worth asking about this option.

Q&A

- What is the purpose of an oil filter element?

The oil filter element is designed to protect the engine by removing contaminants from the oil stream. The contaminants may be particles, sludge, or carbon deposits. When the engine runs, the components rub against each other, leading to the production of debris and particles. Over time, these particles can accumulate in the engine, causing wear and tear or even damage. If left unfiltered, the oil will carry the contaminants, resulting in engine problems. The oil filter element acts as a barrier, ensuring that only clean oil flows into the engine.

- How often should the oil filter element be changed?

It is important to change the oil filter element regularly to ensure that the engine is well protected. While changing the filter, it is also advised to change the oil. Manufacturers recommend changing oil and the oil filter element after every 5,000 to 10,000 miles or after six months. However, this depends on how often the car is driven and the driving conditions. If the car is driven in harsh conditions, such as in traffic, it's a good idea to change the oil and the filter after 5,000 miles. Regular maintenance goes a long way in prolonging the life of the engine.

- What are the signs that the oil filter element needs to be changed?

There are several signs that the oil filter needs to be changed. First, the engine may start producing a knocking sound. The knocking sound is produced when the oil does not flow freely into the engine, causing friction and wear. The oil may fail to flow freely if the filter is too clogged. Second, the oil pressure light may stay on for a long period. The oil pressure light indicates that the engine is not receiving enough oil. A clogged filter is one of the reasons why the oil may fail to reach the engine components. Third, the exhaust smoke may change color. The color change is as a result of oil leaking into the combustion chamber. Finally, the oil may appear too dark and gritty. This is a sign that it's not flowing freely into the engine.