paper box machine

Automatic Packing Line Case Carton Box Erecting Forming Sealing Erector Sealer Machine For Small Box

paper box machine

paper box machine

paper box machine

paper box machine

paper box machine

paper box machine

paper box machine

paper box machine

paper box machine

paper box machine

paper box machine

paper box machine

paper box machine

paper box machine

paper box machine

paper box machine

paper box machine

paper box machine

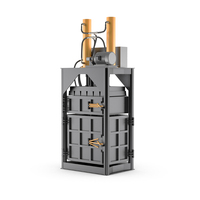

550mm Recycle Waste Cardboard Carton Box Packing Paper Cushion Machine for Logistic Packaging System

paper box machine

paper box machine

Types of Paper Box Machine

A paper box machine refers to a machine that makes paper boxes. The following are some of the most popular paper box machines on the market

-

Paper Cup Making Machine:

The paper cup-making machine is a type of paper box machine designed specifically to manufacture paper cups. It automates the production process, ensuring efficiency and precision. Generally, the production of cups involves feeding paper, cup blanks forming, bottom sealing, cup stacking, and cup packing.

-

Paper Box slotting machine:

The paper box slotting machine is primarily intended to create slots or channels in die-cut paper boxes. These slots are used for the insertion of flaps, folds, or openings in the box. The machine operates by feeding the paper onto the platform, and then it creates slots on the paper. The Box Slotting machine can create multiple slots on the paper, and it is available in different sizes and models.

-

Take-out Paper Bags Making Machine:

With the rising demand for alternatives to plastic bags, the production of paper take-out bags has become increasingly automated. This Paper Bag Making Machine is specifically designed to produce paper bags for take-out, shopping, and other purposes. Generally, this machine is highly efficient and can produce thousands of bags per hour.

-

Paper Box Making Machine:

A generic machine is designed to create paper boxes of various shapes and sizes. This machine usually combines multiple functions such as printing, sticking, die-cutting, and folding. Depending on the model's complexity, it might be semi-automatic or fully automatic.

-

Paper Drawer Box Packaging Machine:

This machine is specifically designed to produce drawer-style paper boxes. It automates the formation, gluing, and shaping of the paper to create drawer boxes for packaging purposes. The machine is user-friendly and efficient, with the capability of adjusting the speed and size according to the customer's needs.

-

Pizza Box Printing Machine:

The paper box printing machine is a device used to print various designs, logos, and patterns on paper boxes. These machines are equipped with advanced printing technology, allowing for high-quality printing with precise details. Depending on the model, the machine can print on different types of paper boxes, such as corrugated, cardboard, and Kraft.

Specifications & Maintenance of Paper Box Machines

Specifications

The specifications will differ depending on the type of machine in question and its production capacity.

- Production Capacity: Machines for producing paper boxes come in a range of production speeds. The speed is generally measured in terms of the number of boxes produced per unit of time, such as hours or minutes. Smaller machines may produce 60 to 100 boxes per minute. Industrial-scale machines can produce anything from 200 to 1,500 boxes per minute.

- Box Types: Given the differing requirements in the market, paper box machines are designed to produce distinct varieties of paper boxes. Some machines may be manufactured to produce boxes with partitions, paper tray boxes, fast-food boxes, or boxes for packaging. The majority of paper box machines specialize in a specific box kind.

- Material Compatibility: Not all machines are built to handle the same type of paper. Some may be suitable for biodegradable paper materials, while others are engineered to work with non-recyclable paper. Paper quality for box making includes A-C grade paper, Kraft paper, and grease-proof paper, among others.

- Sizes: The dimensions of paper box machines can vary significantly based on the type of machine and its intended use. Generally, these machines are large in size, with lengths that can reach 4 to 10 meters.

- Automation Level: Machines for making paper boxes come in a variety of levels of automation. Partially automatic machines may require manual operation at some stages, such as material feeding or product taking-up.

Maintenance

- Routine Inspection: Users should develop a habit of regularly inspecting the paper box machine. This will help to quickly discover potential problems like wear, looseness, or malfunction of components, so they can promptly be resolved or adjust to ensure the machine's stable operation.

- Lubrication Management: The paper box machine consists of many moving parts that require constant lubrication. Users should ensure that each lubricating component is oiled or greased as instructed, to reduce friction and wear, thus extending the lifespan of the machine.

- Cleaning and Dusting: Users should keep the machine and its surroundings clean while regularly removing paper scraps and dust from the device. This will help to lower the thermal burden of the machine, thus reducing the risk of failure.

- Pay Attention to Operating Procedures: Users should pay attention to the operating procedures and requirements of the paper box machine to avoid improper operation and cause damage. They should maintain the machine's efficiency and product quality by using the proper methods.

- Replace Worn Parts: Users should pay attention to the box machine's wear parts, such as belts, blades, bearings, etc. When they show signs of wearing, they should be replaced promptly to ensure the stability and precision of the equipment.

Scenarios of paper box machines

The paper box machine plays a crucial role in various industries that require packaging, as it is responsible for producing packaging boxes and cartons for different sectors. In the food industry, customized paper boxes are used to package products such as pasta, hot dogs, hamburgers, cereals, and milk. To meet this demand, food-grade paper box machines are designed to produce boxes that comply with food safety regulations.

The retail industry relies heavily on paper box machines to produce packaging boxes for countless products, ranging from cosmetics and pharmaceutics to garments and electronic items. These boxes not only serve a functional purpose but also provide an opportunity for brands to showcase their identity through custom-printed packaging.

According to market research, over 8 billion people worldwide watch streaming content every week. The streaming industry and streaming content platforms are booming, resulting in an increased need for advertising. This quantity of advertising leads to a demand for more than 40 million paper boxes used to package advertising items each year.

Moreover, the e-commerce industry has witnessed exponential growth in recent years, thanks in part to the COVID-19 pandemic. This surge has created a significant demand for paper box machines capable of producing shipping boxes and cartons for online retailers. These machines are designed to produce boxes that are not only sturdy and secure but also efficient to pack and ship.

Other industries that use paper box machines include the electronics industry, pharmaceutical industry, toy industry, and agriculture industry, all of which rely on paper box machines to produce packaging boxes that are suitable for their products.

How to Choose Paper Box Machines

Before purchasing the paper box packaging machine, buyers need to evaluate the following key features.

-

Quality and Durability

A food paper box machine makes packaging containers for the food industry, so it is essential that the machine and the boxes it produces can withstand damp and greasy paper. Buyers should look for a machine that works with strong steel components—both the frame and the feeding, folding, and gluing parts.

-

Production Speed

Buyers need to consider the production speed of the machine so as to meet current and future demands. Remember that the speed of the paper box forming machine is influenced by its complexity and automated systems. A simple machine may produce 30 to 60 boxes per minute, but this could rise to 200, 300, or even 600 boxes per minute with a fully automatic machine.

-

Power Consumption

A more automatic and faster machine may use more energy, but this can be expected against the profit it can generate. A machine could help to produce a more profitable product line. A fully automatic machine could be more efficient because workers would only need to change the paper rolls rather than one person needed for multiple tasks in a semi-automatic or manual machine.

-

Packaging Customization

Some machines come with additional tools for further customization. These allow buyers to offer clients more options, which could help to attract more customers and increase sales. Consider the time and cost of getting extra tools and how much more useful and valuable to the business these extras will be.

FAQ

Q1: How does a paper box manufacturing machine work?

A1: The paper box machine forms sheets of paper into boxes using three main processes: forming, cutting, and printing. The paper sheets are fed into the machine, where they are cut and shaped into boxes. Advanced machines can print graphics or text onto the boxes before they are cut and folded.

Q2: What are the advantages of using a paper box machine?

A2: Paper box machines offer several advantages. They allow for mass production of paper boxes, saving time and labor costs. Automated machines ensure consistent quality and accuracy in box production. Large-scale machines can produce up to 1000-12000 boxes per hour, suitable for high-demand businesses.

Q3: What types of paper boxes can a paper box machine make?

A3: A paper box machine can make a variety of paper boxes, including but not limited to, self-locking paper boxes, gable paper boxes, hamburger paper boxes, soda cup paper boxes, pizza paper boxes, and jewelry paper boxes.

Q4: What is the material requirement for a paper box machine?

A4: The main material requirement for a paper box machine is typically a combination of recycled paper fibers and virgin paper pulp. The machine may also need additional materials like adhesives, coatings, or printing inks.