pfaff sewing machine

pfaff sewing machine

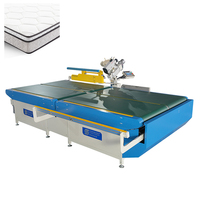

Boway High Frequency 20kHz Ultrasonic Seamless Sewing Machine Industrial China Manufactures in Stock

pfaff sewing machine

pfaff sewing machine

pfaff sewing machine

pfaff sewing machine

pfaff sewing machine

pfaff sewing machine

pfaff sewing machine

pfaff sewing machine

pfaff sewing machine

pfaff sewing machine

pfaff sewing machine

pfaff sewing machine

pfaff sewing machine

pfaff sewing machine

pfaff sewing machine

pfaff sewing machine

TW3-S335VB Pfaff Bag Clothe Industrial Cover Sewing Machine 335 Single Needle Lockstitch for Plastic

pfaff sewing machine

pfaff sewing machine

pfaff sewing machine

Types of PFAFF sewing machines

As a professional, buyers may want to know about the different types of sewing machines, especially if they have just heard about a pfaff sewing machine for the first time and are curious to know more about it. PFAFF offers a wide variety of sewing machines to meet distinct needs, from home sewing to industrial application. Here are some common types:

- Patch sewing machine

Patch sewing machines are commonly used in various industries to sew patches on different materials. They are widely utilized in the clothing and textile industry for patching up holes or tears. Patch sewing machines are designed to create neat and precise stitches on patches of fabric. They come in different models, including those that can perform intricate stitches.

- Upholstery sewing machine

The upholstery sewing machine is commonly used in the furniture industry for stitching upholstery fabrics. It is a heavy-duty sewing machine designed to handle thick and heavy materials used in upholstery, such as leather, canvas, and vinyl. The machine features a powerful motor and a walking foot mechanism that allows it to stitch multiple layers of fabric with ease. Upholstery sewing machines produce strong and durable stitches that can withstand the rigors of everyday use.

- Label sewing machines

Label sewing machines are used to attach labels to various items, such as clothes, bags, and textiles. They are commonly used in the garment and textile industries for branding and identification purposes. Label sewing machines are designed to sew labels onto products with precision and accuracy. They come in different models, including those that can sew labels of different shapes, sizes, and materials. Label sewing machines are easy to operate and can be used to attach woven, printed, or embroidered pfaff labels to products.

- Walking foot sewing machines

Walking foot sewing machines, also known as compound feed sewing machines, are designed to feed multiple layers of fabric through the machine simultaneously. They are commonly used for sewing thick and heavy materials, such as leather, canvas, and upholstery. Walking foot sewing machines have a unique walking foot mechanism that helps to prevent fabric shifting and ensure even stitching. They are popular among quilters, seamstresses, and upholsterers for their ability to handle difficult fabrics with ease and precision.

Specification and maintenance of Pfaff sewing machines

- Pfaff sewing machine specifications

Stitch type: Pfaff sewing machines can support various stitching types, including straight, zigzag, overlock, and more complex embroidery pfaff stitches.

Stitch speed: This refers to how fast the sewing machine can create stitches. Industrial Pfaff sewing machines have faster stitch speeds than household models.

Thread handling: This describes how many threads the sewing machine can handle. Overlock models have the capability of managing multiple threads simultaneously.

Operation mode: This is basically how the sewing machine is powered. For instance, by electricity, battery, or manual operation. Power source: Industrial Pfaff sewing machines are sometimes powered by electricity, but many others are powered by compressed air (pneumatic).

Power source: Industrial Pfaff sewing machines are sometimes powered by electricity, but many others are powered by compressed air (pneumatic).

- Maintenance of Pfaff sewing machines

Regular cleaning: Users should remove dust, lint, and other debris from the sewing machine. Cleaning the machine helps prevent clogs and maintain optimal performance.

Thread and needle maintenance: Users should use the correct type and size of thread and needle for their sewing projects. This helps avoid unnecessary strain on the machine. Users should also ensure the threads and needles are properly inserted and adjusted to enable smooth sewing.

Lubrication: Many Pfaff sewing machines require regular lubrication to keep the moving parts in good working order. Users should refer to the manual to determine the specific lubrication points and recommended lubricants.

Check and adjust the tension: Thread tension is crucial for neat and sturdy stitches. Users should regularly check and adjust the tension of the upper and lower threads to ensure they match the sewing machine's threading guidelines.

Replacing worn parts: Over time, some parts of the sewing machine, such as the needles, threads, and belts, may wear out and require replacement. Users should check these parts regularly and replace them whenever necessary.

Scheduled maintenance: In addition to routine maintenance, users should schedule professional inspections and maintenance according to the manufacturer's recommendations. Skilled technicians can identify and address potential problems before they become serious.

Scenarios

Sewing machines are utilized in various scenarios where garments need to be altered or repaired. Here are some of the most common scenarios where sewing machines are used:

- Textile and Garment Manufacturing:

In textile and garment manufacturing industries, sewing machines are utilized in large-scale production settings. These machines can efficiently sew together fabric pieces to make clothing, accessories, and other textile products. Specially designed sewing machines are used for tasks such as serging, buttonholing, and applying zippers to streamline the manufacturing process.

- Home-based Businesses and Crafting:

Sewing machines for home-based businesses and crafts are an excellent way for small-scale business owners or hobbyists to create unique items. These items might include children's clothing, personalized gifts, home decor, and accessories. Business owners can use these sewing machines to experiment with different techniques and designs to produce distinct products that appeal to niche markets.

- Repair and Alteration Shops:

Rather than disposing of damaged or ill-fitting clothing, alteration and repair shops can use sewing machines to mend garments. These machines can also personalize items to fit the customer's body and style preferences more accurately. Sewing machines are indispensable tools for these businesses, where precise stitching and attention to detail are paramount.

- Industrial Settings:

Industrial sewing machines are used in a variety of settings to create and repair textiles. For example, upholstery sewing machines are used to create and repair furniture, car seats, and other heavy fabric items. Leather sewing machines are used for stitching leather, a material that regular sewing machines can't handle because of its thickness and toughness. Finally, canvas sewing machines are utilized for creating and repairing canvas, a durable fabric commonly used in items like tents, sails, and bags.

How to choose Pfaff sewing machines

When selecting the right Pfaff sewing machine for resale, the following tips should be considered:

- Customer preferences

Consider the different customer needs and preferences. Some customers may be looking for industrial sewing machines for large-scale projects, while others want a compact machine for home use. Take time to understand the target market and ensure the product range caters to different customers. Stock a variety of Pfaff sewing machines, including industrial, computerized, mechanical, and automatic models, to meet various customer needs.

- Volume and budget

Think about the resale volume and budget. Pfaff sewing machines are available in different price ranges. Consider the budget, expected profit margin, and target customers when selecting a sewing machine model. Select a model that will provide a good profit margin while meeting customer needs. Also, think about the volume of sewing machines to stock. Start with a small quantity and gradually increase the order based on customer demand. Begin with popular models and expand the product line as the business grows.

- Product specifications

Examine important product features such as the type of stitches, speed control, presser feet, and automatic threading. Choose sewing machines that are user-friendly and have useful features. Also, focus on the quality of the sewing machine. Go for models manufactured with durable components and materials. Also, check the warranty period and after-sale services offered by the supplier.

- Supplier selection

Choose a reliable supplier with a reputation for quality products and excellent customer service. Research different suppliers, read reviews, and ask for recommendations from other retailers. Also, consider the supplier's delivery time and payment terms. Negotiate for competitive pricing and discounts to maximize profits.

Q&A

Q1: What kind of sewing machine does PFAFF use?

A1: PFAFF mainly uses a unique IDT system that combines the functions of a walking foot and a standard presser foot. In addition, the IDT system is also a key feature of PFAFF sewing machines.

Q2: Are older PFAFF sewing machines better?

A2: Older PFAFF sewing machines are not necessarily better, but for people who are already accustomed to using older models, it may take some time to adapt to newer models. Therefore, whether the old PFAFF sewing machine is better depends on the specific situation.

Q3: What does PFAFF smart select mean?

A3: SmartSelect is a feature available on some PFAFF sewing machines, allowing users to choose their desired stitch length and width by simply pressing a button. This feature helps streamline the sewing process and improve efficiency.