pipe bender

pipe bender

pipe bender

pipe bender

pipe bender

pipe bender

pipe bender

pipe bender

pipe bender

pipe bender

pipe bender

pipe bender

pipe bender

pipe bender

pipe bender

pipe bender

pipe bender

pipe bender

pipe bender

pipe bender

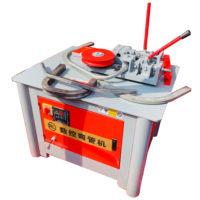

A pipe bender is a tool to bend pipes and tubes into shapes or angles precisely. It is commonly used in plumbing, construction, automotive, and metalworking industries to create bends in pipes for various applications. There are several varieties of pipe benders, such as electric, hydraulic, and manual variants, and each is appropriate for a certain size and kind of pipe.

Types of pipe benders

First, manual pipe benders are operated by hand and are suitable for bending smaller-diameter pipes. They are compact, portable, and easy to use, making them ideal for light-duty bending tasks. Manual pipe benders typically come with dies of different sizes to accommodate various pipe diameters. Second, hydraulic pipe benders use hydraulic pressure to bend pipes efficiently and accurately. They are capable of bending larger-diameter pipes with greater precision and control than manual benders. Hydraulic pipe benders are commonly used in industrial settings for heavy-duty bending applications. In addition, electric pipe benders are powered by electricity and offer automated bending capabilities. They are designed to bend pipes quickly and consistently. Electric pipe benders can handle a variety of pipe sizes and are appropriate for high-volume bending applications. Finally, CNC pipe benders are automated machines that can bend pipes with high precision and repeatability. They are programmable and can bend pipes into complex shapes and angles with minimal manual intervention. CNC pipe benders are used in manufacturing facilities to produce customized pipe components.

How does a pipe bender work?

The user of a pipe bender pulls the bender's handles to force the pipe around the former (shoe). Because the tube is squeezed between the former and the roller, the pipe takes the former's shape when the operator presses the handles together. To push the pipe, people must apply pressure, but the pipe must keep its shape to retain it in good operating order. The pipe bender will have to be larger or thicker than the pipe that has to be bent. Longer handles allow for greater force to be applied to the tube. The shoe must precisely fit the pipe to avoid distortion by retaining it. To construct a precise bend at the correct angle, measure where on the pipe people want to bend and how far around the former they need to bend. To aid with it, the former frequently have angle markings.

Applications of pipe benders

First, pipe benders are commonly used in the plumbing industry to bend pipes for water supply, drainage, and gas systems. They are used to create bends in pipes to navigate around obstacles, corners, and other structures in buildings. Pipe benders ensure that pipes are bent accurately to fit the required layout and dimensions of plumbing systems. Second, in the HVAC industry, pipe benders are used to bend pipes for ductwork, ventilation systems, and refrigeration lines. They help create bends in pipes to connect heating and cooling components, such as air handlers, ducts, and condensers. Pipe benders ensure that HVAC systems are properly installed and function efficiently. Finally, pipe benders play a crucial role in the automotive industry for bending exhaust pipes, roll cages, and custom tubing for vehicles. They are used to create bends in pipes to optimize exhaust flow, reduce back pressure, and enhance vehicle performance.