pir machine

pir machine

pir machine

pir machine

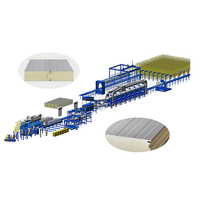

Continuous Cold Room Corrugated PU PIR Polyurethane Sandwich Ceiling Panel Machine / Production Line

pir machine

pir machine

pir machine

pir machine

pir machine

pir machine

pir machine

pir machine

pir machine

pir machine

pir machine

pir machine

pir machine

pir machine

pir machine

pir machine

pir machine

Types of PIR Machines

A PIR machine is commonly used for applying hot-pour 2-component polyurethane (PU) foam, which makes up the core of insulated panels. This device can be handheld, foamed, or fitted to a spray truck. The truck-mounted spray rig is the most productive method and involves mixing the foam in a proportioning machine and spraying it onto the back of the metal sheet as it goes through the spray truck.

Producing PIR foam requires a foaming agent and other additives that permeate and stabilize the mixture to create a lightweight insulating foam. Several types of machines can spray the foam:

-

Portable Spray Foam Machine:

This device, also known as an air-shift spray foam machine, uses compressed air to shift the products that are mixed together in the proportioning unit and sprayed with the applicator. Air compression is the only energy requirement for this machine, making it portable and versatile so that users can apply material to any area from any angle. It has a different mixture than electric and hydraulic spray foam machines, which have more moving parts to function.

-

Foam Pump Spray Foam Machine:

Also known as a hydraulic spray foam machine, this works by having the foam exit the machine through a hose rather than air shifting it. This method has less energy loss and creates a higher output, and the foam produced has a finer detail. However, this machine is more movable than air-shift machines and may need to be set up more to use.

-

Truck-Spray Foam Rig:

Proportioning systems can be mounted in pickup trucks or trailers, creating a spray foam truck rig. Repairing, insulating, or energy-conserving homes with foam in the walls and then insulating the walls with foam is one of the more common approaches to using this type of machine. Rigid foam insulation is created when the foam is dry and used inside walls, and up to 50,000 board feet of foam can be in one truck.

-

SKID (Forklift)]:

A skid foam insulation machine is a mobile platform used to provide onsite foam insulation. Insulation material is mixed in the foam rig and dispensed in cavities as the insulation material moves through the machine toward the nozzle. Using this mobile platform is an efficient and cost-effective way to get energy requirements met by foam insulation. This acts as a more industrially mobile platform, unlike spray foam machines, which are more portable and easier to travel with. Using a skid provides more foam quantity and is a more industrial application.

Specifications and maintenance of pir machines

The specifications for a pir packing machine may vary depending on the type and model. Here are some general specifications for these machines:

-

Production capacity

This refers to the amount of product the machine can package per unit of time. For example, a pi3r package machines may have production capacity of 30 to 100 packs per minute.

-

Packaging size and dimensions

Pir packaging machines can package products that are within the dimension of 5 to 50cm in length, 5 to 30cm in width, and 5 to 15cm in height. Also, depending on the design of the pirs, the packages can have varying sizes and dimensions.

-

Packaging materials

A packaging machine for pirs can use different types of materials. These include plastic (PVC, PP, PETG), paper (kraft paper, coated paper), and recycled materials. The choice of material depends on the design and function of the machine.

-

Machine dimensions

The dimensions of a packaging machine for pir could vary based on the type and model. However, most machines are about 1.5m to 2.5m in length, 1m to 1.5m in height, and 1m to 1.5m in width. Large machines take up more space.

-

Power and Voltage

The power of a PIR package machine is between 1.5kW to 3kW. The voltage is usually 220V or 380V, which is a single-phase or three-phase power supply system.

Maintaining a packaging machine for pirs is very important. Regular maintenance keeps the machine in good operating condition and causes fewer breakdowns and repairs. Here are some important maintenance tips:

- Regularly clean the machine. This helps to get rid of any packaging residue or debris. It also prevents dirt build-up that can affect performance.

- Lubricate moving parts of the machine occasionally. Parts such as chains, rollers, and bearings need lubricating from time to time. Lubrication minimizes wear and tear and reduces friction.

- Regularly inspect the mechanical components for damage. Look for loose parts and worn or damaged components. Routine inspection allows for early detection of issues that can lead to repairs.

- Calibrate the settings on the machine from time to time. These include the speed, tension, and alignment settings. This ensures packaging accuracy and consistency.

- Keep spare parts nearby and replace them as soon as possible to prevent damage to the machine.

Applications of pir machines

-

Food and Beverage Industries

The food and beverage industries are some the major application areas for the pir machines. These are employed in numerous applications such as bottling, packaging, and sealing of diverse food items. The machines help in ensuring that the content of the bottles are intact, fresh, and consumable. In the beverage industry, they are used to package products such as soda, juice, water, and alcoholic drinks.

-

Pharmaceuticals Industry

Pir machines play a major role in the pharmaceuticals industry. Medications typically come in bottles, especially liquid medicines. These bottles need to be properly sealed to ensure the right dosage is intact, safe, and secure. Consumers won't have to worry about the integrity of the medicine when they see a sealed bottle. The integrity of the bottle is very crucial and important to both the consumer and manufacturer. Furthermore, tamper-proof pir machines are essential to ensuring that consumers won't have to worry about over-the-counter medications.

-

Cosmetics and Personal Care

The cosmetics and personal care industry also makes use of pir machines. Products such as lotions, oils, perfumes, and other similar products typically come in pir bottles. Tamper-proof pir seals can help consumers to validate the integrity of the product packaging. It's safe to say that in addition to keeping the product fresh, personal care, and cosmetic companies also use pir machines to enhance the consumer experience.

-

Home and Industrial Chemicals

Household and industrial chemicals also utilize the pir machines in packaging/storing products like detergents, cleaners, solvents, lubricants, and other chemical products that are sold in bottles. The chemicals are bottled in order to provide easy application and usage for consumers. Home and industrial chemical companies utilize pir machines not only for easy application but also to prevent leakage, contamination, end-user safety, and product integrity. Home consumers will be more familiar with the detergent pir and the safety that comes with it is sealed securely. Industrial consumers will also expect the same seal of confidence with their chemical products. Thus, the need for pir machines in chemical packaging is further justified.

How to choose pir machines

-

Consider demand:

Before selecting a specific type of PIR packaging machine for food, it is crucial to conduct market research and understand customer needs and preferences. Identify the target market and the types of food that require packaging. Considering this will help in choosing a machine that is suitable for the packaging requirements of the food products in question.

-

Assess packaging requirements:

Different food items have distinct packaging requirements regarding packaging materials, sizes, shapes, and sealing mechanisms. Determine the packaging requirements for the specific food products and choose a machine that can handle the required packaging materials, sizes, and sealing mechanisms.

-

Consider machine features:

When selecting a specific PIR food packages machine, it is essential to depend upon packaging efficiency, flexibility, and automation level. Consider the machine's speed, capacity, and ability to handle various packaging formats. Choose a machine that can meet the business's specific packaging needs and help streamline packaging operations.

-

Think about integration options:

Packaging is an integral part of the overall production process. Consider integration options provided by different machine manufacturers and choose a machine that can easily integrate with existing production lines and other equipment. For example, consider machines with conveyor systems, labeling systems, and quality control features for a seamless packaging process.

Pir machine FAQ

Q1: What does a PIR machine do?

A1: A PIR (pay-at-the-pump incentive pricing) machine is an fuel pricing device used to communicate with motorists on the pricing of fuel at the dispensing pump. It encourages consumers to purchase fuel at a lower price by making them do a minimal purchase required before they are granted access to purchase the fuel.

Q2: What is the difference between PIR and IPIR?

A2: An IPIR (Integrated Price Indication and Rate Control) is a type of pricing indication and rate control system that integrates various functions for rate management and price presentation. Essentially, it combines the features of PIR into a more comprehensive system of price indication and control.

Q3: What is the advantage of using a PIR machine in a fuel station?

A3: The advantage of using a PIR machine at a fuel station includes; reduced queuing time, improved pump productivity, enhanced customer service, improved security, flexible payment options, pricing transparency and priot pump access.