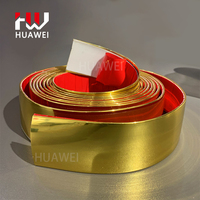

plastic edge strip

plastic edge strip

plastic edge strip

plastic edge strip

plastic edge strip

plastic edge strip

plastic edge strip

plastic edge strip

plastic edge strip

plastic edge strip

plastic edge strip

plastic edge strip

plastic edge strip

plastic edge strip

plastic edge strip

plastic edge strip

plastic edge strip

plastic edge strip

plastic edge strip

plastic edge strip

plastic edge strip

Types of Plastic Edge Strip

A plastic edge strip is used to finish the exposed edges of different materials. This includes wood, metal, glass, or any other surface that requires finished edges. It is also known as PVC edge banding. These strips come in different colors, textures, and finishes to match the surface they are applied to. They can also be customized according to requirements.

These plastic edge strips are an important part of many industries, including construction, furniture making, and automotive industries. They are important because they give materials a finished look and protect them from damage and environmental factors. There are different types of plastic edge strips, and they are listed below:

-

PVC Edge Banding

PVC edge banding is a commonly used plastic edge strip. It is preferred because it is economical and has good quality. Edge banding is made from polyvinyl chloride, which is a widely used plastic material. This makes it easy to use. PVC edge banding has different designs and finishes, which include wood grain, matte, and glossy. It can be customized according to requirements. PVC edge banding is durable and resistant to wear, which makes it suitable for different applications.

-

ABS Edge Banding

ABS edge banding is made from Acrylonitrile Butadiene Styrene plastic material. It is a popular edge banding because it is strong and has a smooth surface. ABS edge banding is available in different colors and finishes, which gives it aesthetic versatility. It is resistant to UV and yellowing, which makes it suitable for applications that are exposed to sunlight. ABS edge banding is simple to apply because it can be edgebanded with hot melt adhesive.

-

PMMA Edge Banding

PMMA edge banding is also known as acrylic edge banding. It is made from acrylic plastic material. This edge banding is loved for its glossy and clear appearance. PMMA edge banding is available in different colors and finishes. It is resistant to impact and has good hardness. PMMA edge banding can be used in applications that require materials to be visible through the edge strip. Edge banding is available in transparent, frosted, and colored options.

-

Melamine Edge Banding

Melamine edge banding is made from melamine-coated paper. It is a popular plastic edge strip because it is lightweight and economical. Edge banding is available in different textures and finishes. They include wood grain and smooth matte. Melamine edge banding is suitable for low-traffic applications. It is used mainly in furniture and cabinetry where cost efficiency is more important than high performance.

Function and feature of plastic edge strip

-

Protection:

Plastic edge strips are primarily important for protecting furniture from impacts and damage. They are usually placed on the edges of tables, counter tops, or any other surface that can be hit. These strips act as a barrier, preventing the corners from getting scratches or dents due to daily use or accidental bumps. This not only helps keep the furniture in good shape but also prolongs its lifespan because, without these strips, the corners can easily break or crack. So, these edge strips are vital for protecting the furniture from any impact damage it may encounter.

-

Aesthetic Appeal

Plastic edge strips serve important functional roles, but they also have aesthetic benefits. They come in different colors, designs, and finishes, allowing users to choose the ones that match their interior design. When these edge strips are added, they create a cohesive and finished look by blending with the furniture or contrasting it. This enhances the visual appeal of the furniture and the entire space. For businesses, first impressions matter, and a well-designed office or retail space is more welcoming to customers. Plastic edge strips improve the space's overall appearance and make it more presentable for clients and customers.

-

Cornering and finishing

Plastic edge trim strips are important for finishing and cornering in construction projects. These strips provide a clean, professional look to corners and joints in walls, floors, or any surface. They hide rough edges, wires, or seams, making everything look neat and finished. This is important in construction because no one wants to see exposed wires or rough edges on furniture or anywhere else. Everything needs to look polished and put together. These edge strips are important for hiding those imperfections and creating a visually appealing surface. For example, in a painted wall, plastic edge strips can be used to cover the paint's edge where it meets the floor or ceiling. This creates a smooth transition that is pleasing to the eye.

Scenarios of Plastic Edge Strip

There are several applications for edge strips in the plastic industry. These are some common usage scenarios.

-

Furniture Manufacturing

Edge plastic molding strips are used on drawers, cabinets, and tables. They give a finished look to furniture. The edge strips also prevent the wood from chipping. Edge strips are also used on chairs and sofas. They cover the raw edges of the upholstery.

-

Kitchen and Bathroom Remodeling

Kitchen cabinets are fitted with edge plastic molding strips. They make the cabinets look nice and protect them from damage. The strips are also used on countertops. They cover the edges of the countertops and prevent people from bumping into hard corners. The strips are also used on bathroom vanities and shower areas.

-

Office and Commercial Spaces

Plastic edge strips are used on reception desks and conference tables. They make these spaces look professional. The strips are also used on filing cabinets and bookshelves. They add style to the office. Edge strips are also used on counter service areas in restaurants.

-

Retail Displays

Edge strips are fitted on display shelves and racks. They protect the edges from bumps and give them a finished look. The strips are also used on mannequins and display tables. They make the displays look attractive and invite customers.

-

Educational Institutions

Plastic edge strips are used in classrooms and libraries. They are also used in auditoriums. The strips protect surfaces from wear and tear. They also prevent injuries from sharp edges.

-

Healthcare Facilities

Edge strips are used on hospital furniture. They are also used on medical cabinets and carts. The strips make the furniture easy to clean. They also prevent injuries from sharp edges.

-

Industrial Applications

Plastic edge strips are used in factories and warehouses. They are also used in workshops. The strips protect equipment and surfaces from damage. They help prevent accidents caused by sharp edges.

-

DIY Projects

Plastic edge strips are used in many do-it-yourself projects. They are used to fix old furniture and give it a new look. The strips are also used on shelves, picture frames, and storage boxes. They add a decorative touch and protect the edges.

How to choose plastic edge strip

Choosing the right edge banding for a specific application involves considering several factors. Here are some crucial factors one should consider before buying plastic edge strips in bulk:

-

Functionality

The primary purpose of the plastic edge banding should be considered first. This will guide the selection and ensure that the edge banding meets the requirements. For example, if the edge banding is to be used on work surfaces, then an impact-resistant and waterproof edge strip should be selected. The same case applies to furniture and cabinets.

-

Intended use

The way the plastic edge strip is intended to be used has a direct impact on how it is chosen. For example, if the edge strip is to be used on tabletops or surfaces that will be frequently cleaned, then an easy-to-clean and durable edge strip should be selected. In this case, ABS edge banding would be an ideal choice due to its ease of cleaning and durability.

-

Thickness and color

When choosing edge banding, it is important to consider the thickness of the edge banding. Ensure that the selected edge banding is not thicker than the substrate. It is also important to consider the color of the edge banding to ensure it matches the color of the furniture or cabinet for aesthetic purposes.

-

Availability of the matching veneer

In cases where wood edge banding is used, it is important to consider the availability of a matching veneer. This is to ensure that a cohesive look is achieved. However, with plastic edge strips, this may not be a big issue since these edge bands come in different colors and textures that can easily match the furniture or cabinetry.

Plastic Edge Strip Q&A

Q: What are the benefits of using a plastic edge strip?

A: Edge strips provide decorative and functional benefits. They cover the raw edges of materials, preventing chipping, damage and splinters. Plastic edge trim offers a finished look while providing impact resistance. It is available in different colors, patterns and textures that match or enhance the surfaces they border.

Q: How should bulk plastic edge strips be installed?

A: Installation methods depend on the type of trim selected. Pressure-sensitive adhesive (PSA) strips are simply pressed into place. Adhesive-backed trims require the removal of a liner, proper placement, and firm pressing to bond the edge securely. Hot-melt adhesive trims need a special applicator to provide the required heat for installation. Clips-and-slots or snap-on trims are installed without any adhesive.

Q: How should plastic edge strips be cleaned and maintained?

A: The edge strips should be cleaned with a soft cloth and mild detergent. Harsh chemicals, abrasive cleaners, or tools that may scratch the edge strips should be avoided. For plastic sheets with textured surfaces, a soft brush may be used to remove dirt or debris. Edge strips should be kept out of direct sunlight to prevent color fading over time.

Q: Are the bulk plastic edge strips customizable?

A: Yes, the edge strips are fully customizable. They are available in different sizes, colors, textures, and profiles to meet specific design requirements. Customers can provide their specifications for the desired trim to be manufactured. Some suppliers also offer a logo printing service on the edge strips.

Q: What are the common thicknesses of edge strips?

A: The most common thicknesses are 0.5mm, 1mm, 1.5mm, 2mm, and 3mm. The thickness affects the durability and appearance of the edge. Thicker edges provide better impact resistance while thinner profiles create a more seamless look.