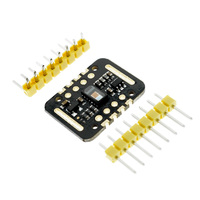

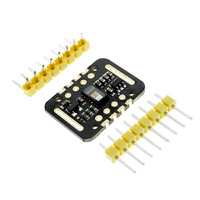

ppg sensor

ppg sensor

ppg sensor

ppg sensor

ppg sensor

ppg sensor

ppg sensor

ppg sensor

ppg sensor

ppg sensor

ppg sensor

ppg sensor

ppg sensor

ppg sensor

ppg sensor

ppg sensor

ppg sensor

ppg sensor

ppg sensor

ppg sensor

ppg sensor

Types of PPG Sensors

A PPG sensor is a photoplethysmographic (PPG) sensor that detects blood volume changes in microvascular tissues. The PPG sensor uses a light-based technology to measure blood volume changes and provide real-time data on blood flow and heart rate. PPG sensors are used in smartwatches and fitness trackers. The main types of PPG sensors include:

-

Reflectance PPG sensors

Reflectance PPG sensors use light to measure blood volume changes in the skin. They emit green, red, or infrared light and measure the amount of light reflected back to the sensor. The changes in the reflected light indicate changes in blood volume and allow the sensor to monitor heart rate and blood flow. The reflectance PPG sensor is used in smartwatches and fitness devices.

-

Transmittance PPG sensor

The transmittance PPG sensor measures the variation of light intensity that passes through the tissue. It has a light emitter and a light detector placed on opposite sides of the tissue. The transmittance PPG sensor provides more accurate readings of blood volume changes. However, it is mostly used in medical devices since it requires more invasive placement.

-

Wearable Ppg sensor

A wearable PPG sensor is a device worn on the body to monitor physiological signals. It provides real-time data on heart rate, blood oxygen levels, and stress levels. The sensors are embedded in smartwatches and fitness trackers. Some common types of wearable PPG sensors include wrist-based sensors, ring-based sensors, and ear-based sensors.

-

Implantable Ppg sensor

An implantable PPG sensor is placed inside the body through a surgical procedure. It continuously monitors physiological signals such as heart rate, blood pressure, and blood oxygen levels. The implantable PPG sensor provides critical data for disease management and health monitoring. It is used in pacemakers and other medical devices. Some common types of implantable PPG sensors include cardiovascular sensors, orthopedic sensors, and neurostimulation sensors.

-

Optical Ppg sensor

An optical PPG sensor uses light to monitor blood flow and heart rate. It has advanced technology, such as lasers and digital signal processing, to improve measurement accuracy and reduce noise.

-

Wireless Ppg sensor

A wireless PPG sensor is any PPG sensor that uses wireless technology to transmit data. The data can be transmitted to a smartphone or computer for further analysis. It allows remote monitoring of physiological signals. The wireless PPG sensors are implantable, transcutaneous, and wearable.

Specification and maintenance of ppg sensor

Manufacturers of PPG sensors consider several specifications to ensure they meet the needs of different markets. Here are some of the key specifications of a PPG sensor.

-

Sampling Rate

The sensors have different sampling rates depending on the application. For instance, medical-grade PPG sensors have a high sampling rate of 100Hz to 200Hz. On the other hand, fitness trackers have a lower sampling rate of about 50Hz.

-

Wavelength

PPG sensors use different wavelengths to detect blood volume changes. Most sensors use green light, while some advanced ones use a combination of green, red, and infrared light. The combination of these wavelengths in the PPG sensor allows for more accurate readings.

-

Size and Form Factor

Different PPG sensors come in various sizes and shapes depending on their application. For instance, wrist PPG sensors are the size of a watch, while implantable sensors are the size of a grain of rice. The size and form factor of a PPG sensor determine its functionality and accuracy.

-

Power Consumption

Power consumption is an important specification of PPG sensors. Wearable sensors are designed to have low power consumption to enable prolonged battery life. Implantable sensors have higher power consumption because they are always active and continuously monitoring the blood flow.

-

Signal-to-Noise Ratio (SNR)

The signal-to-noise ratio is a critical specification for all PPG sensors. It measures the strength of the PPG signal relative to the background noise. Sensors with a higher SNR provide clearer signals, which leads to more accurate measurements.

-

Material

The material used in the construction of a PPG sensor is also an important specification. Sensors that are designed for medical use are constructed using biocompatible materials. On the other hand, fitness sensors can be made from cheaper and less durable materials.

-

Calibration

PPG sensors require different levels of calibration depending on their application. For example, medical-grade sensors need to be calibrated frequently to maintain accuracy. On the other hand, PPG sensors used in everyday applications do not require calibration.

PPG sensors have different maintenance requirements depending on their application. Here are some common maintenance requirements for PPG sensors.

-

Cleaning

PPG sensors need to be cleaned regularly to remove dirt, sweat, and dust that may affect their functionality. Users can use a damp cloth to wipe the surface of the sensors. It is also important to refer to the manufacturer's instructions to avoid using cleaning agents that may damage the sensor.

-

Battery Replacement

Wearable PPG sensors require regular battery replacement or recharging to ensure they function optimally. Users should incorporate battery maintenance practices such as avoiding overcharging and using the recommended battery.

-

Software Updates

PPG sensors require regular software updates to enhance their functionalities. Users should follow the manufacturer's instructions on how to perform the updates. Software updates may also include firmware updates that improve the performance of the PPG sensor.

-

Physical Inspection

Regular physical inspection of the PPG sensor can help identify any signs of damage. Users should regularly check for cracks, scratches, or any other physical damage that may affect the functionality of the sensor. If there is any physical damage, the sensor should be replaced.

-

Connection

Regular checks should be made to ensure that the PPG sensor is properly connected to the monitoring device. Loose connections may result in inaccurate readings or data loss.

How to choose PPG sensors

Choosing the right PPG sensor requires careful consideration of several factors:

- Target population: Consider the target population and their specific needs. Selecting a PPG sensor that meets the requirements of the intended user group is essential.

- Monitoring requirements: Consider the monitoring needs. Selecting a PPG sensor with appropriate capabilities, such as heart rate variability or oxygen saturation, depending on the clinical purpose, is essential.

- Usability and convenience: Sensor selection should be made with usability and convenience in mind. This includes considering aspects such as size, weight, and display readability, as well as the data transfer frequency and software interface.

- Clinical validation: Choosing a clinically validated PPG sensor is essential. This ensures that the sensor's accuracy and reliability have been confirmed through rigorous testing and comparison with reference standards.

- Cost-effectiveness: Finally, cost-effectiveness is an essential consideration. While more expensive sensors may offer advanced features or higher accuracy, evaluating whether these advantages align with the specific monitoring requirements is essential.

How to DIY and Replace PPG Sensor

Some PPG sensors are portable and easy to wear on the body. It is easy to check the battery level and charge the device when needed. PPG sensors that are implanted in the body are not easy to replace. A healthcare professional will be required to perform surgery and remove the old sensor and replace it with a new one. This will be done in a sterile environment to avoid contamination and infection.

It is advisable to always consult the user manual to get the right steps for replacing a PPG sensor. Different manufacturers have different models and their replacement procedures may differ. Below are some general steps that can be followed when replacing a PPG sensor that is worn on the body.

- 1. Remove the old sensor from the skin and clean the area.

- 2. Ensure that the new sensor is fully charged before applying it on the skin.

- 3. Follow the manufacturer's instructions on how to apply the new sensor.

- 4. Connect the new sensor to the mobile device or smartwatch.

- 5. Calibrate the new sensor if required.

- 6. Dispose of the old sensor according to the manufacturer's instructions.

- 7. Monitor the new sensor to ensure it is working correctly.

Q&A

Q1: How Long Does a PPG Sensor Last?

A1: The longevity of a PPG sensor depends on its usage and environmental conditions. Generally, if used and maintained properly, its lifespan can be up to two years or more.

Q2: Can a PPG Sensor Be Used for Blood Pressure Monitoring?

A2: PPG sensors cannot be used to monitor blood pressure directly. However, it can be used to estimate blood pressure variations and trends in some cases.

Q3: What Should I Do if My PPG Sensor Gives Unusual Readings?

A3: If the PPG sensor provides inconsistent readings, ensure that it is properly installed and that the battery is charged. Moreover, the sensor should be clean, and the skin should be dry where it is attached. If it continues to provide irregular readings, consult a healthcare professional.