ratchet strap

ratchet strap

ratchet strap

ratchet strap

ratchet strap

ratchet strap

ratchet strap

ratchet strap

ratchet strap

ratchet strap

ratchet strap

ratchet strap

ratchet strap

ratchet strap

ratchet strap

ratchet strap

ratchet strap

ratchet strap

ratchet strap

ratchet strap

ratchet strap

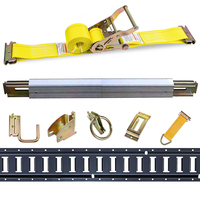

Types of Ratchet Strap

Ratchet strap is a kind of tied down strap that uses a ratchet mechanism to allow a load to be tightened safely and securely. The ratchet strap is also called a ratchet tie-down strap. It consists of a textile strap, ratchet handle, and hooks. The straps come in various sizes and weight capacities. They are used in several applications that require secure cargo. The ratchet strap is commonly used in lashing vehicles, trailers, and motorcycles.

There are different types of ratchet straps. They include;

- Wide Ratchet straps: Wide ratchet straps are suitable for heavy-duty applications. The width of the strap offers a bigger surface area that distributes the load. This reduces the chances of damage to the cargo. The straps are used in securing large and heavy freight. They come in various working load limits.

- Low Profile Ratchet straps: Low-profile ratchet straps have a low-profile ratchet wheel. This makes them ideal for applications where clearance is limited. The straps offer flexibility and are used in various applications.

- Wire Hook Ratchet Strap: Wire hook ratchet straps have wire hooks on both ends. The hooks are used to attach to anchor points during the ratcheting process. The wire hooks come in various designs. For instance, they can have a spring or safety latch to offer extra security when fastening the load.

- Double J Hook Ratchet Strap: This type of ratchet strap has double J hooks on both ends of the strap. The J hooks are used to attach to anchor points or fitting points on the load. The double J hooks offer a stable attachment, making ratchet straps suitable for securing large freight.

- Flatbed Truck Ratchet Strap: Flatbed truck ratchet straps are designed for use on flatbed trucks. The straps come with special fittings that allow them to be attached to the railing of a flatbed truck. They are used to secure cargo during transport.

- Camouflage Ratchet Strap: Camouflage ratchet straps are designed in various camouflage patterns. They are used in applications where discreet ratcheting is required. For instance, during wildlife transport, the camouflage ratchet straps can be used to avoid attracting attention to the cargo.

Specifications and maintenance of Ratchet Strap

Working Load Limit

WLL on a ratchet strap is the maximum weight that can be safely tied down without breaking the strap. For instance, a ratchet strap with a WLL of 1,500 kg can tie down cargo weighing 1,500 kg safely. It's essential to consider the WLL when purchasing ratchet straps.

Tensile Strength

It is the strength of the strap itself, calculated by pulling out a sample until it breaks. The tensile strength should be higher than the WLL to provide a safety margin. For example, a strap with a tensile strength of 3,000 kg can have a WLL of 1,500 kg.

Material

This is the type of fabric used to make the ratchet strap. The material should be strong and durable. Common materials include polyester, which is strong and resistant to UV rays, and nylon, which is more robust than polyester but weaker and not as durable as polyester.

Width

The width of a ratchet strap can affect its strength. Wider straps can tie down larger and heavier cargo, while narrower ones are suitable for smaller and lighter loads. Ratchet straps are available in various widths, from 19 mm to 50 mm or more.

Length

They are available in different lengths, from 2 m to 10 m or more. The length required depends on the size of the cargo and the space available to tie it down. Longer straps offer more flexibility for larger loads.

End Fittings

It is the type of fitting at the end of the ratchet strap used to attach the strap to the cargo. Common end fittings include hooks, loops, and flat fittings. The type of end fitting required depends on the type of cargo and the method of attaching the strap.

Ratchet Mechanism

This is the mechanism used to tighten the strap. It should be smooth and easy to operate, allowing the user to tighten the strap quickly and securely. The ratchet mechanism should also be durable and require little maintenance.

Ergonomic Considerations

It is Important when using ratchet straps, especially for long periods. Features such as comfortable handles and levers can reduce hand fatigue and make the ratchet mechanism easier to operate. This is especially important for those who use ratchet straps frequently or for extended periods.

Safety Standards

These are specifications that ratchet straps must meet to ensure safety and reliability. These standards are established by organizations such as AS/NZS 4380:2001 and EN 12195-2:2001. Ratchet straps that meet these standards are tested and verified to be safe for use in cargo tying down.

Maintenance

Maintaining a ratchet strap is essential to prolong its life and ensure its safety during use. Here are some maintenance tips: Always clean the ratchet strap after use to remove dirt, dust, and debris. Use a soft cloth or brush and mild soap and water. Inspect the ratchet strap regularly for signs of wear, tear, and damage. If the strap is worn or damaged, replace it immediately to ensure safety during use. Store the strap in a dry place, away from direct sunlight and extreme temperatures. Prolonging the strap's life is essential, as moisture and heat can weaken the fabric.

How to Choose Ratchet Strap

Before buying a ratchet strap for retail, it's important to understand the factors that influence its quality and performance. Here are the key factors:

-

Load Capacity

When choosing a ratchet strap, considering the safe working load (SWL) and the breaking strength (BS) is important. The SWL is the maximum load that can be transported safely, while the BS is the ultimate strength of the strap. Buyers should select ratchet straps with an SWL greater than the intended load to ensure safety and reliability in all applications.

-

Length

Ratchet straps come in different lengths, which influences their use. Longer straps offer more versatility for larger loads, while shorter straps are more suitable for smaller applications. Buyers should choose a length that suits their needs and the type of cargo they intend to transport.

-

Width

The strap width also affects its application. Wider straps offer more surface area for load distribution and secure better grip, making them ideal for heavy and large loads. On the other hand, narrower straps are more suitable for delicate or smaller cargo.

-

Hook Types

Different ratchet strap hook types are available, and each offers a unique benefit. For instance, S-hooks are common and suitable for general use, while J-hooks offer more security but require more attachment effort. Buyers should choose a hook type that suits their application and provides secure attachment.

-

Material

The material of a ratchet strap influences its durability and strength. Polyester is a common material for ratchet straps and offers excellent strength and abrasion resistance. It is also important to consider environmental factors such as exposure to chemicals or extreme weather conditions when choosing a material.

-

End Fittings

The end fittings of the ratchet strap also influence its performance and application. Different types of end fittings are available, such as sewn loops, flat loops, and wire hooks. Buyers should select end fittings that suit their needs and provide secure attachment and load stability.

-

Ratchet Mechanism

The ratchet mechanism itself is a critical aspect to consider when choosing a ratchet strap. Look for ratchet levers that are easy to operate and offer smooth engagement and disengagement. Some ratchet mechanisms also have a release feature that facilitates load unloading. Additionally, consider the material and construction of the ratchet mechanism to ensure durability and reliability.

How to DIY and Replace Ratchet Straps

Replacing a ratchet strap is a simple process that can be done with a few basic tools. Here's a step-by-step guide on how to replace a ratchet strap:

- Choose the Right Replacement Strap: Select a new ratchet strap that matches the size, strength, and length requirements of the load being secured.

- Unload the Existing Strap: Fully open the ratchet mechanism and remove any webbing or load from the old strap.

- Remove the Old Strap: Depending on the attachment method (bolted, stitched, etc.), remove the old ratchet strap from its mounting point.

- Prepare Mounting Points: Clean and inspect the mounting points where the ratchet strap will be attached. Replace any damaged hardware if necessary.

- Attach the New Strap: Position the new ratchet strap in the same orientation as the old one (ensure the correct placement of the ratchet mechanism). Secure it to the mounting points using the appropriate method (e.g., stitching, bolting).

- Thread the Webbing: Follow the same threading path as the old strap, ensuring the webbing is correctly routed through the ratchet mechanism and any other relevant components (e.g., hooks, loops).

- Test the New Strap: Before using the load, test the ratchet mechanism to ensure it operates smoothly and the strap is properly tensioned.

- Secure the Loose End: Once the load is secured and the desired tension is achieved, use the provided keeper or hook to secure the loose end of the webbing.

- Perform Final Inspection: Double-check the strap's placement, tension, and security to ensure everything is in order before transporting or storing the load.

Q and A

Q1. How should someone use a ratchet strap properly?

A1. To use a ratchet strap properly, ensure the load is stable and the strap is positioned correctly. One end should go under or through the load, and the other should connect to the ratchet tool. After the strap is properly placed, the ratchet should be cranked back and forth until the load is secure. Always double-check that the load is secure before moving it.

Q2: How much weight can a ratchet strap pull?

A2. The amount of weight a ratchet strap can pull depends on its working load limit (WLL). This limit is determined by the strap's size, material, and construction. It's essential to always adhere to the WLL to prevent accidents and equipment damage.

Q3: Can ratchet straps be replaced?

A3: Yes, replacing ratchet straps is possible and often necessary if the straps become worn, damaged, or compromised in any way. Regularly inspecting ratchet straps for signs of wear or damage is essential to ensure safety and reliability.

Q4: What are the different types of ratchet straps?

A4: There are several types of ratchet straps, each designed for specific applications and load-securing needs. Some common types include: 1. Flatbed straps: Used to secure loads on flatbed trailers. 2. Wheel straps: Designed to secure vehicles by wrapping around the wheels. 3. Specialty straps: Customized ratchet straps for specific industries or applications.

Popularity Trends

The keyword "ratchet strap" shows a significant fluctuation in web search volume, averaging 60,500 monthly web searches over the past year. Despite a notable three-month decrease of 18%, the overall one-year change indicates a robust 22% increase in interest.

Analyzing the monthly data, the web search volume for "ratchet strap" peaked during the summer months, reaching 74,000 web searches from June to September 2024. This was followed by a return to the yearly average of 60,500 web searches in October. Notably, there were dips in February and March 2024, where web search volumes dropped to 49,500. This pattern suggests seasonal variations, with higher interest during the warmer months, possibly due to increased activities such as moving and outdoor storage needs.

The trends observed in the web search volume for "ratchet strap" highlight a clear seasonal demand, with peaks during the warmer months and a noticeable decline during the colder seasons. This insight into consumer behavior can help businesses in the vehicle and storage category to better plan their marketing and stock strategies, aligning promotions and inventory levels with these peak times.