rebar bender

rebar bender

rebar bender

rebar bender

rebar bender

rebar bender

rebar bender

rebar bender

rebar bender

rebar bender

rebar bender

rebar bender

rebar bender

rebar bender

rebar bender

rebar bender

rebar bender

rebar bender

rebar bender

rebar bender

rebar bender

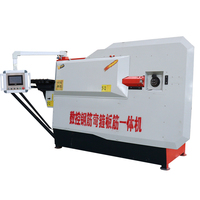

In the construction industry, many tools and machines are used to ensure that the job is done effectively and efficiently. One such tool is the rebar bender, a machine designed to bend steel bars and rods in different shapes and patterns according to construction requirements.

Types of rebar benders

There are several types of rebar benders available in the market. The first type is a manual rebar bender. This type is often used for small-scale projects where precision and control are needed more than speed. Another type is the electric rebar bender, which is powered by electricity and can bend rebar at a very high speed. This type is used for large-scale projects where a lot of rebar needs to be bent quickly. The third type is the hydraulic rebar bender, which uses hydraulic pressure to bend the rebar. This type of bender is highly efficient and can bend large diameters of rebar. Finally, there's the rebar bender and cutter. This type is versatile as it not only bends the rebar but also cuts it to the required length.

Applications of rebar benders

Rebar benders have a wide range of applications in the construction industry. They are used in building foundations, roads, bridges, and other structures that require reinforced concrete. The rebar bending tool is used to bend the rebar to the required shape and pattern, which strengthens the structure and ensures its stability. In addition, rebar benders are also used in industries such as the manufacturing of cages used in tunnels, precast segments, and poles. The rebar bending machine ensures consistency and accuracy in bending the rebar, which is crucial for the structural integrity of the construction.

Materials used in rebar benders

The materials used in the construction of rebar benders play a significant role in their durability and performance. The majority of the rebar benders are made from good-quality steel. The parts of the machine that come into direct contact with the rebar, such as the rebar cutter, are typically made from hardened steel to withstand the pressure and wear. Some high-end models of rebar bender harbor freight are made from alloy steel for increased strength and durability. In addition, some parts of the rebar bender, like the handle in a manual flat bar bender, are coated with rubber or plastic for a comfortable grip.

A rebar bender is an essential tool in the construction industry. It comes in various types, each designed for a specific application and made from materials that ensure its durability and effectiveness. Whether it's for a small-scale project or a large-scale construction, there's a rebar bender that will meet the specific needs of the project.