reflux water condenser

reflux water condenser

reflux water condenser

reflux water condenser

reflux water condenser

reflux water condenser

reflux water condenser

reflux water condenser

reflux water condenser

reflux water condenser

reflux water condenser

reflux water condenser

reflux water condenser

Lab Water Refrigerant Reflux Bulbed Straight Coiled Glass Condenser with Standard Ground Mouth Joint

reflux water condenser

reflux water condenser

reflux water condenser

reflux water condenser

reflux water condenser

reflux water condenser

reflux water condenser

Types of Reflux Water Condensers

A reflux water condenser is one of the most crucial pieces of equipment in distillation processes. It is available in two major types: vertical and horizontal reflux water condensers. Both types return distillates to the column for further separation instead of collecting them as products.

-

Vertical Reflux Condensers

-

Horizontal Reflux Condensers

A vertical reflux water condenser has a tall, cylindrical shape. The prefix "upward" in its name describes how heat and vapor move through the condenser. Fittingly, the vapor first travels up the column before passing through the cooling coils. The reflux water condenser uses the gravity of the distillate to descend back into the column. Vertical reflux condensers are further divided into types: Liebig, Liebig with a Tap, Adrian, Ria, and Double Pipe Cold Finger.

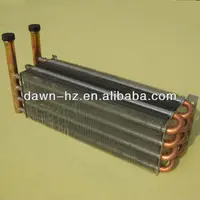

Unlike their vertical counterparts, horizontal reflux condensers have a horizontally long cylinder shape. Vapor moves through the refrigerant coil in a horizontal direction. It then refluxes back down. Horizontal reflux condensers are typically used for large-scale industrial applications. They are more common in factories or commercial places. The two main types are shell-tube horizontal reflux condensers and air-cooled horizontal condensers.

Specifications and maintenance of reflux water condensers

- Materials: Reflux condensers are typically made of stainless steel or glass. The strong steel material offers good corrosion resistance, heat resistance, and durability. Glass reflux water condensers provide good visibility for the process of distillation. This is also useful for monitoring the flow of condensed liquid within the condenser.

- Size: The sizes of the reflux condenser can be represented by various lengths, diameters, and weights. Generally, the size of reflux condensers is proportional to the size of the distillation apparatus. This means that larger reflux condensers are used for larger distillation apparatuses, and vice versa. For example, a small reflux condenser table may be 30 cm in length with a diameter of 3 cm. Meanwhile, an industrial condenser would be over 100 cm with a large diameter.

- Function: Reflux water condensers are primarily used for distillation, separation, and purification in chemical, pharmaceutical, and food industries. They condense ascending vapors back into liquids, which are then collected in the distillation flask.

- Cooling type: There are two main types of cooling for reflux water condensers. One is the horizontal reflux condenser, which uses cold water flowing through the exterior jacket. The other is the vertical type that allows cooled water to flow from the top to the bottom through the inner tube.

Proper maintenance of the reflux condenser is important to ensure its normal operation, thus prolonging its service life. Cleaning the reflux condensers types is the primary maintenance task of the equipment. The boom reflux condenser should be thoroughly cleaned after each use to prevent the residual liquid from solidifying inside and becoming difficult to remove. During the cleaning process, it is best to soak the condensate in a suitable cleaning solution to thoroughly clean even the tiny inner parts.

Periodic inspection of the reflux condenser is also important. Users should carefully check the reflux condenser for any signs of damage or leakage, such as cracks, deformations, or loose fastening parts. If any problems are found, they should be repaired or replaced promptly to avoid safety hazards or equipment failures. Users should also pay attention to the sealing condition of the reflux condenser, ensuring that all sealing parts are well sealed and prevent any leakage from occurring.

In addition, users of the reflux condenser need to pay attention to the temperature control of the equipment. This is very important for distillation and separation processes. For example, if the temperature of the reflux condenser is too high, the condensation of vapor may not occur properly. As a result, there will be no reflux process, which may hinder the purification and separation of the mixture. On the other hand, if the temperature of the reflux condenser is too low, the condensation of the vapor may exceed the condensation capacity and lead to a blockage of the equipment. Therefore, customers need to adjust the cooling water flow and temperature from the reflux condenser to ensure that its operating temperature is within an appropriate range.

Applications of a Reflux Water Condenser

The reflux condenser plays a crucial role in numerous industries and chemical laboratories. Below is a list of some key applications of a reflux condenser.

-

Food Industries

A vacuum reflux condenser is widely used in the food industry to extract valuable food compounds. For instance, in thechemical food extraction process of essential oils, flavors, natural antioxidants, and phytochemicals from food products like spices, fruits, or plants using a reflux condenser can improve the quality of the final product. The high temperature and pressure used in a reflux condenser allow a more concentrated extraction of the compounds, resulting in a high yield of essential oils and flavors.

-

Chemical Synthesis and Reaction

Reflux condensers are integral to chemical synthesis and reaction processes. They allow chemical reactions to occur precisely by maintaining constant temperature and pressure. Reflux condensers enable chemists to carry out various chemical reactions, including esterifications, hydrogenations, oxidations, and more freely within defined time frames. Using a reflux condenser during chemical reaction processes also helps to avoid the addition of more reagents, lowering costs while increasing efficiency.

-

Pharmaceuticals

The pharmaceutical industry widely uses reflux condensers in drug development and production. Reflux condensers enable chemists to create and synthesize complex molecules, leading to the production of active pharmaceutical ingredients (APIs), intermediates, and fine chemicals. Furthermore, reflux condensers help to enhance the purity and yield of pharmaceutical compounds by facilitating multiple crystallizations, extractions, and purifications.

-

Petrochemical and Refining

Reflux water condensers are critical in the petrochemical and refining industries. They support fractional distillation processes to separate crude oil into various petroleum products such as gasoline, diesel, kerosene, jet fuel, and more. Reflux condensers facilitate the production of high-quality fuels, lubricants, plastics, and other petrochemical derivatives by improving separation efficiency and resolution.

-

Environmental Applications

Reflux condensers play a key role in environmental applications like waste treatment and pollution control. They support techniques such as solvent recovery, advanced oxidation processes (AOPs), and wet air oxidation (WAO) to minimize environmental impact. Reflux condensers improve waste treatment facilities' recovery rates and biodegradability by preserving reagents and enhancing reaction efficiency. This eventually results in reduced waste generation and environmental sustainability.

How to choose a reflux water condenser

-

Understand the types:

Buying a reflux water condenser starts with understanding different types. Task-specific performance becomes achievable when businesses get familiar with the distinct functions that each type embodies. For instance, an upward reflux condenser is ideal for distilling volatile chemicals, while a downward one may work better in organic synthesis involving high boiling points.

-

Focus on material quality:

Material selection has a significant impact on the efficacy of condensers. Stainless steel, particularly hastelloy c-276, and borosilicate glass play essential roles in ensuring durability and thermal resistance.

Stainless steel offers robustness and high corrosion resistance, especially if it is made of superior alloys like hastelloy c-276, making it suitable for harsh chemical environments. On the other hand, borosilicate glass has certain benefits such as optical transparency and resistance to thermal shock, which allow scientists to observe the condensation process closely in real-time. These unique features foster safety precautions during experimental endeavors.

-

Assess the size and connection:

Choosing the right size and connections for a reflux condenser are essential to its applicability and ease of use. This can ensure a proper fit with apparatus or other devices commonly used in a laboratory. Also, good performance and seamless cooperation among different equipment can be achieved through appropriate sizes and connections.

-

Think about temperature control:

Temperature-control ability is a crucial factor in the effectiveness of a reflux condenser. There are some options ranging from adjustable cooling water flow rates to thermostatic baths. Consider such flexibility to precisely manage the reaction temperature.

-

Check safety features:

Safety happens to be a primary consideration when selecting a reflux condenser. Users can browse models equipped with protective devices such as anti-orthogonal screens, pressure relief valves, and explosion-proof permission.

Enhanced lifespan and safer utilization are made possible by the selection of condensers that take user safety into account.

-

User reviews and ratings:

Users' feedback can give references more than just the appearance and specifications of the product. Their ratings and comments contain valuable information regarding usage experiences, advantages, and shortcomings.

Before making a final decision, it is important to conduct research and read reviews to learn about the performance and reliability of different products.

Q&A

Q1: What are the differences between a reflux condenser and a regular condenser?

A1: The two types of condensers function the same way but have different mechanisms. A regular condenser will only allow the vapor to cool down and condense the liquids. A reflux condenser controls the flow of liquid within the condenser and allows some liquids to flow back to the distillation flask.

Q2: How are reflux condensers classified?

A2: Reflux condensers can be classified by the type of cooling they offer. Water-cooled reflux condensers are commonly used in laboratory distillations. They utilize the flow of cooling water to remove heat from the vapor, facilitating condensation. Air-cooled reflux condensers, on the other hand, rely on ambient air cooling, which makes them suitable for less efficient distillation setups.

Q3: How effective is a reflux condenser?

A3: The efficiency of a reflux condenser is often evaluated based on its capacity to return condensed liquid to the distillation flask. With proper cooling and flow rates, reflux condensers can achieve near quantitative condensation, maximizing the utilization of the distillation pot contents.

Q4: Can a reflux condenser be cleaned?

A4: Yes, it is possible to clean the reflux condenser. Manufacturers suggest cleaning the condenser both internally and externally using a suitable cleaning solution to get rid of any deposits, contaminants, or residues.