rubber wood timber

rubber wood timber

rubber wood timber

rubber wood timber

rubber wood timber

rubber wood timber

rubber wood timber

rubber wood timber

rubber wood timber

rubber wood timber

rubber wood timber

rubber wood timber

rubber wood timber

rubber wood timber

rubber wood timber

rubber wood timber

rubber wood timber

rubber wood timber

rubber wood timber

rubber wood timber

rubber wood timber

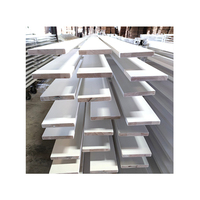

Types of Rubber Wood Timber

Rubberwood is a sustainable choice for furniture and other wood products. It's a hardwood with a dense grain and offers good durability, which is good for making furniture that lasts. Additionally, it is eco-friendly because it comes from rubber trees that have already been harvested for their latex. Using these trees for timber helps to maximize their value and reduce waste.

Rubberwood is renowned for its light, natural hue, which can range from pale cream to light brown. This allows it to blend well with different types of furniture. Its fine, even grain makes it a popular choice for manufacturers who want to add a bit of color or texture to their furniture.

Rubberwood timber is used in the manufacture of furniture such as tables, chairs, cabinets, and beds. It is also used to make household items like cutting boards, toys, and decorative items. The timber is also used to make veneer, which is a thin layer of wood glued onto surfaces to provide a more attractive appearance while keeping costs down.

Rubberwood is a versatile and sustainable option for timber, and its popularity continues to grow among manufacturers and consumers. Below are the major types of rubber wood timber:

- Standard Rubber wood: This wood is obtained from matured rubber trees that are about 25 years or older. The timber is used in the production of furniture, cabinets, flooring, and construction. It is also used to make household items like toys, cutting boards, and decorative items. Additionally, it is used to make rubberwood veneer, which is a cost-effective alternative to solid wood.

- Engineered wood: Also known as composite wood, this type of wood is manufactured by binding or fixing the fibers of wood using adhesives under heat and pressure. Engineered rubber wood, for instance, uses a portion of the outer bark layer, which is rich in latex. This wood is popular for making furniture, cabinets, and plywood. It is also used for making particleboard and medium-density fiberboard (MDF) that are used in construction.

- Reclaimed rubberwood: This wood is harvested from old rubber plantations or from rubber trees that have reached the end of their productive lifecycle for latex extraction. This type of wood is popular for making furniture and decorative items. It is also used for making flooring and cutting boards.

- Processed rubberwood: This type of timber undergoes various treatments to enhance its properties and durability. For instance, some processed rubberwood is treated with chemical compounds to make it more resistant to insects and fungi. Others are steamed to change its color and increase its stability. Processed rubberwood is popular for making fine furniture, cabinets, and high-quality wooden products.

Functions and features of rubber wood timber

- Affordable: Because of its accessibility, rubberwood is a popular choice among homeowners and furniture producers. After the latex extraction process, the trees are often cut down, making this wood an economical option for those looking to build or buy furniture and other items.

- Durability: Rubberwood is renowned for its durability and long-lasting characteristics. Because of this, it is a preferred choice for producers of furniture and other items. Rubberwood is able to withstand typical wear and tear, making it a practical and economical choice.

- Easy to work with: Rubberwood is simple to shape, cut, and glue, making it perfect for various uses. Because of this quality, it is a preferred choice for producers of furniture and other wood products.

- Attractive grain: Rubberwood has a lovely, straight grain that gives any product a classic and elegant appearance. This quality makes it a popular choice for furniture and decorative items.

- Environmental benefits: Because of its sustainability and eco-friendliness, rubberwood is a favorite among environmentally aware consumers. The wood is harvested from old rubber trees that are no longer productive, which helps to preserve the environment and promote sustainable forestry practices.

- Resistance to pests and decay: Rubberwood has natural characteristics that make it resistant to insects and decay, which adds to its longevity. This quality makes it a preferred choice for outdoor furniture and structures.

- Versatility: Rubberwood can be used for various applications, including furniture, cabinetry, flooring, and decorative items. Its adaptability makes it a popular choice among producers and designers.

- Simple maintenance: Rubberwood furniture and products are simple to maintain. They only need a little cleaning with a moist cloth and occasional polishing to keep them looking beautiful and last for many years.

- Latex-free: Rubberwood is a wonderful choice for those with latex allergies because it is usually free of latex. This feature makes it a secure and pleasant choice for those with latex sensitivity.

- Lightweight: Rubberwood is a lightweight timber, making it simple to move and manage. This quality makes it a popular choice for furniture that must be assembled and moved.

Scenarios of Rubber Wood Timber

Rubberwood is a popular choice among manufacturers and craftsmen due to its versatility and eco-friendliness. It is employed in different applications across industries, offering durability and attractive aesthetics. Here are some of the common usage scenarios of rubber wood timber:

-

Furniture Manufacturing

Rubberwood is extensively utilized in crafting various furniture items. Its fine grain and smooth surface make it suitable for aesthetically appealing and functional furniture. This timber is commonly used in manufacturing bedroom furniture sets, including beds, nightstands, and dressers. Additionally, rubber wood timber is used to manufacture living room furniture such as sofas, coffee tables, and entertainment units. Furthermore, this timber is used to manufacture storage units like cabinets and drawers.

-

Home Decor Elements

Rubberwood is used in manufacturing decorative and functional home items. It is a sustainable option for homeowners looking to improve their environmental impact. Additionally, rubber wood timber is used to manufacture decorative wall art, picture frames, and mirrors.

-

Kitchen Accessories and Furniture

Rubberwood is popular for crafting kitchen furniture and utensils due to its non-toxic properties. It is a preferred choice for manufacturing kitchen cabinets, countertops, and dining tables. These furniture pieces are long lasting and require little maintenance. Additionally, rubber wood is used in manufacturing cutting boards, utensils, and food storage containers.

-

Office Furniture

This timber is used to manufacture a wide range of office furniture. Its durability and strength make it a suitable choice for heavily used furniture. For instance, rubber wood is used to make office desks, chairs, filing cabinets, and bookshelves. Its ability to blend with different decor styles makes it a popular choice for modern and traditional offices.

-

Musical Instruments

Rubberwood is used in crafting various musical instruments. Its dense nature offers excellent acoustic properties. Additionally, rubber timber is used in manufacturing pianos, guitars, and other percussion instruments. Its stability ensures that these instruments maintain their tuning and shape over time.

-

Construction and Carpentry

Rubberwood is used in various construction applications. Its strength and durability make it a suitable choice for long lasting construction. For instance, rubber timber is used in constructing doors, windows frames, and flooring. Additionally, it is used in crafting built-in furniture, such as bookshelves and benches.

-

Children's Toys and Play Equipment

Rubberwood is a popular choice for manufacturing children's toys and play equipment. Its non-toxic nature makes it a suitable choice for products that come into direct contact with children. For instance, rubber wood is used in manufacturing building blocks, puzzles, and educational toys. Additionally, it is used in crafting play sets, such as slides, swings, and climbing frames.

How to choose rubber wood timber

-

Source and Sustainability

It's important to find out where the rubberwood is sourced from. Rubber trees are usually harvested in Southeast Asia, especially in countries like Malaysia and Thailand. Sustainable sources are very important because they make sure that the forests stay healthy and that the wood is available for a long time. When choosing rubber wood timber, pay attention to certifications such as FSC (Forest Stewardship Council) and PEFC (Programme for the Endorsement of Forest Certification). These certifications show that the timber was cut from sustainably managed forests.

-

Quality and Grading

Rubber wood timber comes in different quality levels and grades. It is important to check the quality of the timber to make sure it is suitable for the intended use. For example, if timber is needed for furniture construction, select rubber wood timber with fewer knots and blemishes. However, if rubber wood is needed for landscaping or decorative structures, lower-grade timber may be sufficient.

-

Moisture Content

The moisture content in the rubber wood timber affects its durability and stability. When the moisture content is high, it means that the timber is still fresh. However, if the moisture content is low, it means that the timber has been properly seasoned. Properly seasoned rubber wood timber has a moisture content of between 8% and 12%. This moisture content indicates that the timber is stable and will not warp or crack during the construction process.

-

Dimensional Accuracy

When choosing rubber wood timber, consider the timber's dimensional accuracy. This refers to the precision with which the timber has been cut. Select timber that has been cut with accuracy. This is because timber with accurate dimensions will fit together perfectly when constructing. This will result in a finished product that is visually appealing.

rubber wood timber Q & A

Q1. What are the disadvantages of rubberwood?

A1. Rubberwood has many advantages, including being environmentally friendly and affordable. However, it has some disadvantages, such as being vulnerable to insect attacks and requiring proper care and maintenance to ensure longevity.

Q2. Why is it called rubberwood?

A2. It is called rubber wood timber because it comes from rubber trees (Hevea brasiliensis). These trees are primarily cultivated for natural latex rubber production. Once the trees reach the end of their productive life (about 25-30 years), they are harvested for wood. This process helps to utilize the entire tree, promoting sustainability. Rubberwood is known for its strength, durability, and resistance to warping, making it a popular choice for furniture and other wooden products.

Q3. Is rubberwood high in quality?

A3. Yes, rubberwood is considered to be of high quality. It is dense, durable, and stable, meaning it does not warp or shrink easily. Rubberwood is also easy to work with, allowing for smooth cutting, shaping, and finishing. This makes it a popular choice for furniture and other wooden products.

Q4. How long will rubberwood last?

A4. Rubberwood can last for many years if properly cared for and maintained. Its lifespan also depends on factors like usage, environmental conditions, and quality of manufacturing. Generally, rubberwood furniture can last between 25-35 years.