silk reeling machine

silk reeling machine

silk reeling machine

silk reeling machine

silk reeling machine

silk reeling machine

silk reeling machine

silk reeling machine

silk reeling machine

silk reeling machine

silk reeling machine

silk reeling machine

silk reeling machine

silk reeling machine

silk reeling machine

silk reeling machine

silk reeling machine

silk reeling machine

silk reeling machine

silk reeling machine

silk reeling machine

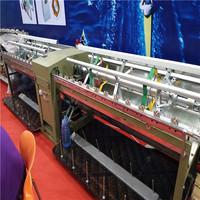

Types of silk reeling machines

The process of extracting raw silk from silk cocoons is called Cocoon reeling. The process involves unwinding the threads from the cocoons using a machine called a Silk reel machine. There are several types of silk reeling machines used in the industry for mass production of silk filaments.

-

Automatic Silk Reeling Machines

The silk filaments are produced in huge quantities and undulated simultaneously. An automatic feeding mechanism is included in these machines to continuously provide cooked cocoons for reeling. The automatic take-up system in the machine coils the silk onto bobbins or spools. Automatic machines also include temperature and humidity control systems that regulate the conditions within the reeling chamber. These machines have revolutionized the silk industry by streamlining the production process and improving efficiency. With their automated features and advanced controls, automatic silk reeling machines have significantly reduced manual labor requirements while ensuring consistent product quality.

-

Lightweight and Easy-to-Use Reeling Machines

Modern silk reeling machines are sleek and portable. They allow users to set up the machine easily and comfortably without extra help. The lightweight machines enable easy transportation. This assists rural entrepreneurs who can take the machine to silk cocoon suppliers and produce silk on location. Ease of use encourages self-employment and income generation in rural areas.

-

Single Cocoon Reeling Frames

Using a single cocoon, reeling frames allow the delicate uncoiling of silk fibers. The basic structure of the frame consists of a horizontal or vertical axis around which fine threads are wound. Small holders or troughs are placed on this axis to hold individual cooked cocoons. With their simple setup, these frames can reel out silk from different types of cocoons, including the most common – Bombyx Mori.

The simplicity of single cocoons makes them ideal for small-scale production but limits their capacity compared to industrial-scale reeling machines. Additionally, farmers and artisans can easily afford to use them in remote rural areas.

-

Tensiometers and Tension Control Devices

Modern reeling machines are often equipped with tensiometers to help control the tension of the silk threads as they are being reeled. Tension control is crucial and can affect the consistency, quality, and smoothness of the silk thread. With consistent tension, the machine can produce uniform silk filaments, which will ensure there are no weak spots or interruptions in the thread. The use of tension control devices in these machines helps to maintain the delicate balance between the force required to reel the silk and the gentle handling necessary to prevent damage to the fragile threads.

-

Multi-Cocoon Silk Reeling Machines

These machines mass-produce silk filaments by reeling up to 300 to 600 cocoons simultaneously. They have automatic feeding and take-up systems that efficiently handle cooked cocoons and coiled silk. Multi-cocoon reeling machines are crucial for increasing silk production. Their high capacity meets global silk demand. However, workers must be trained to run complex machines safely. Multi-cocoon reeling machines are key to the silk industry's growth. Their technological advances streamline production.

Specifications and Maintenance

- Applicable: Single Silk Reel Machine is applicable to a single cocoon. The Double Silk Reel Machine applies to double cocoons. The Multiplex Silk Reel Machine is applicable to multiple cocoons.

- Cocoon Feeding: The method by which the cocoons are given to the water reel. There are two common types of feeds, namely pile-feeding and automatic feeding.

- Cocoon Winding: The way the silk is reeled back from the water reel. It can be divided into package winding, silk bobbin, and silk bobbin with traverse.

- Cocoon Cooking: The way cocoons are boiled is divided into traditional boiling vats and modern boiling tanks. The boiling water temperature and time are also crucial. Generally, the temperature is around 98°C and the time is around 30 minutes.

- Cocoon Drying: The manner in which the cocoons are dried is carbonized drying and natural drying. Four stages of drying: drying in hot water, drying in alkaline water, drying in water vapor, and final drying.

Silk reeling machine maintenance is vital in ensuring optimal performance and prolonging its lifespan. Regular maintenance checks and practices can help prevent breakdowns and improve production efficiency. Here are some essential maintenance tips for a silk reeling machine:

- Daily Cleaning: Clean the machine daily to remove any dust, debris, or leftover silk fibers. Use a soft brush or cloth to avoid damaging the machine's parts.

- Lubrication: Apply lubricant to the moving parts of the machine, such as chains, gears, and rollers, to reduce friction and prevent wear and tear. Also, lubricate the oiling points and grease holes as recommended by the manufacturer.

- Tightening Bolts and Nuts: Regularly check and tighten the bolts and nuts to ensure they are adequately fastened. Loose bolts can affect the machine's stability and cause accidental injuries.

- Replace Worn Parts: Check for worn-out or damaged parts, such as belts, blades, and bearings, and replace them as needed to maintain optimal performance.

- Regular Servicing: Schedule regular professional maintenance and servicing for the silk reeling machine to ensure all parts function correctly and identify potential issues before they become major problems.

- Electrical Checks: Regularly inspect the electrical components, including the cables, connections, and switches, to ensure they are not frayed or damaged. Additionally, ensure the machine's grounding system is functional to avoid electrical hazards.

By following these essential maintenance tips, the silk reeling machine can operate smoothly and efficiently for an extended period.

Scenarios in which silk reeling machines are used

The usage scenarios for a silk reeling machine are mostly in the industrial setting but also include the following applications:

- Big-scale production of luxurious satin, satin that's wrinkle-free, silk used in upholstery and raw silk threads for fabrics are all applications that use automated silk reeling machines.

- Small-scale use of electric silk reeling machines can be seen in workshops in Thailand, Italy, Japan and France where small amounts of silk are produced to make specialty silk products that are marketed at a higher price.

- Silk farmers in China, India, Brazil and Thailand use these machines for domestic use. They may have small-scale machines to reel off silk for their own use or to sell to a local market.

- Research and development centers that are studying better ways of producing silk or improving the genetics of silkworms will have these machines to reel off silk to use in their experiments.

- Some educational institutions may have small-scale machines to show students how silk is made and what the whole process looks like. Students are taught about the technology of how these machines work to reel off the silk.

How to Choose Silk Reeling Machines

When buying a reeling machine, core features like quality, efficiency, and types should be top priorities. It's also crucial to source from a supplier with a proven track record.

First, buyers should check the machine's build quality. Machines built with durable materials can withstand wear and tear. In addition, they have reliable performance. Also, examine if the machine has a protective mechanism to prevent accidents during operation.

The next step is to analyze the machine's production speed. Generally, machines with higher speeds can fold more silk in a short time. They also boost production efficiency. However, ensure the speed can be adjusted to suit the specific processing requirements. Consider machines with multiple spinning speeds. Such speeds offer more control over the quality and thickness of the silk being reeled.

Identifying the type of machine is also important when buying. Buyers can choose automatic, semi-automatic, or manual machines. Automatic machines have higher production efficiency and ease of use. However, semi-automatic and manual machines have affordability and simplicity.

Consider machines with digital controls and monitoring systems. Such features provide precise control over parameters like tension, speed, temperature, and humidity. In addition, it enables prompt adjustments to ensure consistent product quality. An easy-to-use interface is another must-have feature. Look for machines with simplified user interface systems for easy operation, even without prior experience.

Finally, buy from suppliers with an ongoing support system. They should provide technical support and maintenance services. Also, the supplier should offer timely spare parts supply to ensure the reeling silk machine operates smoothly without prolonged downtime.

Silk Reeling Machine FAQ

Q1: How does a silk reeling machine work?

A1: The working process of a silk reeling machine may vary depending upon the type and model of the machine. Generally, the machine fetching the mulberry leaves and other types of leaves to feed the silkworms. The machine then moves the silkworms to a basket where they start spinning. Some advanced modern machines can directly transfer the basket to the boiling area where the silk threads are extracted through a process known as gooking.

Q2: What are the types of automated silk reeling machines?

A2: The primary types of automated silk reeling machines are small-scale, medium-scale, and large-scale production machines. The small-scale production machines can reel silk from individual cocoons or small numbers of cocoons simultaneously. Medium-scale machines are semi-automated and require manual intervention but are suitable for medium-scale silk production. Large-scale automated silk reeling machines can reel silk from hundreds to thousands of cocoons simultaneously and are suitable for large-scale industrial silk production.

Q3: What are the benefits of using the automated silk reeling machine?

A3: The automation in the silk reeling process gives precision, uniform silk thread production, and increased yield. The mechanized process helps in faster processing and reduces the manual effort required. The durability of these machines ensures that large-scale silk production can be done without frequent breaks. Modern machines have automatic shut-off mechanisms that prevent over-reeling and damage to the silk thread.