silver welding rod

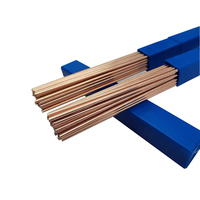

Refrigeration Instrumentation 2% 5% 15% Silver Brazing Alloys Rod Price Silver Solder Rods Weld Wire

silver welding rod

silver welding rod

silver welding rod

silver welding rod

silver welding rod

silver welding rod

silver welding rod

silver welding rod

silver welding rod

silver welding rod

silver welding rod

silver welding rod

silver welding rod

silver welding rod

silver welding rod

silver welding rod

silver welding rod

silver welding rod

silver welding rod

silver welding rod

Introduction to Silver Welding Rod

The silver welding rod is an essential component in the world of metal joining and fabrication. Widely acclaimed for its unique properties, silver welding rods are utilized in various applications ranging from jewelry making to industrial manufacturing. Renowned for their excellent conductivity and corrosion resistance, these rods serve as the preferred choice for welders and metalworkers seeking high-quality results.

Types of Silver Welding Rod

Understanding the different types of silver welding rods available can help you select the right one for your specific needs. These rods generally come in two main categories:

- Flux-Cored Silver Welding Rods: These rods come with a core of flux, which helps eliminate the need for additional fluxing agents during the welding process. They provide cleaner welds with less residue.

- Solid Silver Welding Rods: Made purely from silver, these rods offer superior melting points and strength. They are ideal for applications requiring precise and strong joint formations.

Applications of Silver Welding Rod

The versatility of silver welding rods means they can be employed in various fields. Here are some common applications:

- Jewelry Repair and Creation: Jewelry makers extensively use silver welding rods to create intricate designs and repair delicate pieces.

- Automotive Industry: These rods are used to repair or create components that require high conductivity and strength.

- Electronics: Silver welding rods are ideal for connecting electronic components due to their excellent electrical conductivity.

- Manufacturing and Fabrication: Industries that require precision welding often resort to silver rods for their reliability and performance under high stress.

Features and Advantages of Silver Welding Rod

Choosing silver welding rods for your projects comes with a host of benefits. Here are some key features and advantages:

- High Melting Point: Silver welding rods have a high melting point, making them suitable for various welding tasks including those involving dissimilar metals.

- Corrosion Resistance: Silver is known for its resistance to tarnishing and corrosion, ensuring long-lasting and durable welds.

- Excellent Conductivity: The superior electrical and thermal conductivity of silver welding rods is paramount in electronic and electrical applications.

- Versatility: Suitable for a wide range of materials, including copper, brass, and even gold, silver welding rods are ideal for complex projects.

- Smooth Finish: Silver welding rods provide a smooth finish on welds, reducing the need for post-weld grinding or polishing.