sintering furnace

sintering furnace

sintering furnace

sintering furnace

sintering furnace

sintering furnace

sintering furnace

sintering furnace

sintering furnace

sintering furnace

sintering furnace

sintering furnace

sintering furnace

sintering furnace

sintering furnace

sintering furnace

sintering furnace

sintering furnace

sintering furnace

sintering furnace

sintering furnace

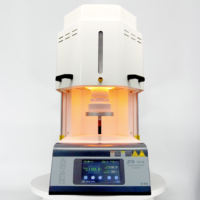

Sintering Furnace: A Comprehensive Overview

A sintering furnace is a vital tool in various industries, serving to merge materials under heat to enhance their physical properties. This process is crucial for creating strong and durable products in fields like ceramics, metallurgy, and powder metallurgy. By understanding the types, applications, features, and advantages of a sintering furnace, businesses can make informed decisions about incorporating this essential technology into their production processes.

Types of Sintering Furnaces

Sintering furnaces are tailored for different applications and materials. The main types include:

- Batch Sintering Furnace: Designed for small to medium production runs, these furnaces allow for multiple loads to be processed individually.

- Continuous Sintering Furnace: Ideal for large-scale operations, this type provides uninterrupted production of sintered materials.

- Vacuum Sintering Furnace: Operates under low-pressure conditions to prevent oxidation and contamination, making it suitable for high-value materials.

- Gas Sintering Furnace: Utilizes controlled gas atmospheres to facilitate sintering, thus improving product consistency and quality.

Applications of Sintering Furnaces

Sintering furnaces find widespread usage across various sectors due to their versatility and efficiency. Key applications include:

- Ceramics Manufacturing: Used extensively for creating ceramic products, including tiles, tableware, and electronic components.

- Metal Powder Processing: Critical in the production of sintered metal parts such as gears and bearings in the automotive and aerospace industries.

- Biomaterials Development: Employed in the fabrication of bioceramics and implants for medical applications.

- Composite Materials: Facilitates the sintering of composite materials, enhancing their strength and performance in various applications.

Features and Advantages of Sintering Furnaces

Sintering furnaces come equipped with numerous features that enhance their usability and effectiveness. Notable features include:

- Temperature Control: Advanced control systems allow precise temperature regulation, essential for achieving desired material properties.

- Atmosphere Management: Many furnaces provide options for atmosphere control, such as vacuum or inert gas, to mitigate unwanted chemical reactions.

- Energy Efficiency: Modern models are designed to optimize energy use, contributing to cost savings and environmental sustainability.

- Data Logging and Monitoring: Integrated software capabilities enable real-time monitoring of the sintering process, enhancing product quality and reproducibility.

The advantages of using a sintering furnace are profound:

- Improved Material Properties: The sintering process enhances the mechanical properties of materials, leading to greater strength, density, and durability.

- Enhanced Product Consistency: Sintering provides uniformity in production, ensuring that each batch maintains high-quality standards.

- Cost-Effectiveness: Reduces the need for additional processing steps, saving both time and resources during manufacturing.

- Versatile Processing Capabilities: Suitable for a wide range of materials and applications, making it a flexible solution for manufacturers.

How to Choose the Right Sintering Furnace

Selecting the appropriate sintering furnace is crucial for achieving optimal results. Consider the following factors:

- Production Volume: Determine whether you require a batch or continuous furnace based on your production scale.

- Material Types: Assess the materials being processed to ensure compatibility with the furnace type and capabilities.

- Temperature Requirements: Check the temperature range of the furnace to ensure it meets the needs of your specific sintering applications.

- Budget and Operating Costs: Evaluate your budget and consider the energy efficiency and maintenance costs associated with different models.

By understanding these key aspects, businesses can select a sintering furnace that aligns with their operational needs and streamlines production processes effectively.