sla machine

sla machine

sla machine

sla machine

sla machine

sla machine

sla machine

sla machine

sla machine

sla machine

sla machine

sla machine

sla machine

sla machine

sla machine

sla machine

sla machine

sla machine

sla machine

sla machine

sla machine

The Ultimate Guide to SLA Machines on

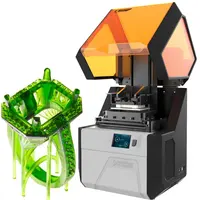

If you are in the manufacturing industry and looking for cutting-edge technology to enhance your production process, SLA machines are a game-changer. These machines, also known as stereolithography machines, utilize resin laser 3D printing technology to create high-precision 3D models with exceptional surface quality.

Technical Specifications and Capabilities

SLA machines on boast impressive technical specifications. They offer high-resolution printing capabilities with layer thicknesses as low as 25 microns, ensuring detailed and accurate prototypes. Additionally, these machines feature large build volumes, allowing you to create prototypes of varying sizes without compromising on quality.

Moreover, resin 3D printing machines on come equipped with advanced slicing software that optimizes the printing process for efficiency and precision. The UV laser technology used in these machines ensures fast curing times, enabling rapid prototyping and production.

Benefits of SLA 3D Printing Machines

Investing in an SLA 3D printing machine from offers numerous benefits for your business. These machines provide high levels of accuracy and precision, making them ideal for creating intricate prototypes and functional parts. Additionally, the smooth surface finish achieved with SLA technology reduces the need for post-processing, saving both time and resources.

Furthermore, resin 3D printing machines are versatile and compatible with a wide range of resin materials, allowing you to choose the best material for your specific application. Whether you need transparent, flexible, or durable parts, SLA machines can deliver exceptional results.

Applications of SLA Machines

SLA machines find applications across various industries, including automotive, aerospace, medical, and consumer goods. In the automotive sector, these machines are used for rapid prototyping of parts and components, accelerating the product development cycle.

Moreover, in the medical field, SLA 3D printing machines play a crucial role in producing custom implants, prosthetics, and surgical guides with unmatched precision. The ability to create complex geometries makes SLA technology invaluable in the healthcare industry.

Choosing the Right SLA Machine

When selecting an SLA machine on , consider factors such as printing speed, resolution, build volume, and material compatibility. Assess your specific requirements and production needs to determine the most suitable machine for your business.

Additionally, look for user-friendly interfaces and reliable customer support to ensure a seamless printing experience. The durability and reliability of the machine are also crucial factors to consider for long-term performance.

Maintenance and Care Tips

To ensure optimal performance and longevity of your SLA machine, follow recommended maintenance practices. Regularly clean the build platform and resin tank to prevent buildup and maintain print quality. Additionally, calibrate the machine periodically to ensure accurate prints.

It is essential to store resin materials properly in airtight containers away from UV light to prevent curing. Conducting routine inspections and servicing of the machine can help identify and address any issues promptly, ensuring uninterrupted production.

By leveraging the advanced capabilities of SLA machines available on , businesses can revolutionize their prototyping and production processes, gaining a competitive edge in the market.