small stepper motor

small stepper motor

small stepper motor

small stepper motor

small stepper motor

small stepper motor

small stepper motor

small stepper motor

small stepper motor

small stepper motor

small stepper motor

small stepper motor

small stepper motor

small stepper motor

small stepper motor

small stepper motor

small stepper motor

small stepper motor

small stepper motor

small stepper motor

small stepper motor

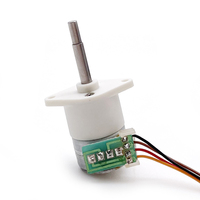

Introduction to Small Stepper Motors

Small stepper motors are compact devices that convert electrical pulses into precise mechanical movements. Widely used in various industries and applications, these motors are celebrated for their ability to provide exceptional control over positioning, speed, and acceleration without the need for feedback systems. Their functionality, efficiency, and compatibility with various technologies make them a popular choice for automation, robotics, and DIY projects.

Types of Small Stepper Motors

Small stepper motors are classified into several types, each suited to specific applications and requirements. Understanding these types aids in selecting the right motor for your project.

- Permanent Magnet Stepper Motors: Utilize permanent magnets in their rotor and offer high torque at low speeds. Ideal for applications requiring holding torque.

- Variable Reluctance Stepper Motors: Operate based on changes in magnetic reluctance; these motors are lightweight and best suited for low-torque applications.

- Hybrid Stepper Motors: Combine features of both permanent magnet and variable reluctance stepper motors. They deliver superior performance, making them suitable for a broad range of applications.

- Bipolar and Unipolar Stepper Motors: Bipolar motors require a more complex wiring setup but provide greater torque, whereas unipolar motors are simpler to control and easier to use for basic applications.

Function and Feature of Small Stepper Motors

The operational mechanics of small stepper motors are rooted in their precise control and advanced features. These motors offer numerous benefits, including:

- High Precision: Stepper motors can accurately control position with a specific number of steps per rotation, often ranging from 200 to 400 steps, making them perfect for applications requiring fine movements.

- Open-loop Control: They can operate without an encoder for feedback, simplifying the system design while still maintaining decent accuracy.

- Reliability: Small stepper motors are known for their durability and reliability over long operational periods, reducing maintenance needs.

- Ability to Hold Position: These motors can maintain a specific position when powered, allowing them to “hold” without continuous power, which can lead to energy savings.

Applications of Small Stepper Motors

Due to their versatile functionality, small stepper motors find applications in numerous industries:

- Robotics: Used for joint movements, precise positioning, and controlling robot arms.

- 3D Printing: Essential for the movement of the print head and the build plate, ensuring correct layering.

- Medical Equipment: Implemented in various devices like syringe pumps and diagnostic machines, where accurate dosing is critical.

- Industrial Automation: Integral in conveyor systems, CNC machines, and automation tools for repetitive precise movements.

- Consumer Electronics: Found in devices like printers, cameras (for focusing), and digital displays for scanning mechanisms.

In conclusion, small stepper motors are an essential component in modern technology, delivering unrivaled precision and versatility. By understanding the types, functionalities, and broad applications of these motors, businesses can harness their potential to enhance automation and innovation in their operations.