spray lubricant and penetrating oil

spray lubricant and penetrating oil

spray lubricant and penetrating oil

spray lubricant and penetrating oil

spray lubricant and penetrating oil

spray lubricant and penetrating oil

spray lubricant and penetrating oil

spray lubricant and penetrating oil

spray lubricant and penetrating oil

spray lubricant and penetrating oil

spray lubricant and penetrating oil

spray lubricant and penetrating oil

spray lubricant and penetrating oil

spray lubricant and penetrating oil

spray lubricant and penetrating oil

spray lubricant and penetrating oil

spray lubricant and penetrating oil

spray lubricant and penetrating oil

spray lubricant and penetrating oil

spray lubricant and penetrating oil

spray lubricant and penetrating oil

Types of Spray Lubricant and Penetrating Oil

Spray lubricant and penetrating oil play a crucial role in reducing friction and wear in machinery, thereby prolonging the lifespan of equipment. They comprise base oils and additives that enhance certain properties, such as viscosity and lubrication performance. Below are some common types of spray lubricants:

-

Graphite Spray Lubricant

Graphite spray lubricant contains graphite particles in a solvent-based or polymer-based carrier. Once the solvent evaporates, the graphite binds to the surfaces, forming a lubricant layer. It is ideal for high-temperature settings or situations where wet lubricants may be problematic.

-

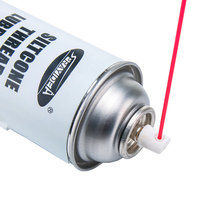

Silicone Spray Lubricant

Silicone spray lubricant incorporates silicone polymers, making it suitable for various applications. It is water-resistant and has superior moisture protection, preventing corrosion. Additionally, it can repel dirt and dust, making it ideal for automotive and electrical components.

-

Oil-based Spray Lubricant

Oil-based spray lubricants utilize mineral or synthetic oils as the primary ingredient. They are good general-purpose lubricants that reduce friction and prevent wear in moving parts. Depending on the formulation, oil-based spray lubricants can have added additives such as anti-wear agents or rust inhibitors.

-

PTFE Spray Lubricant

PTFE spray lubricant contains polytetrafluoroethylene (PTFE) particles, which have excellent non-stick and low-friction properties. The spray forms a thin coating on surfaces, minimizing friction and wear. PTFE spray lubricants are used in applications requiring dry lubrication or where wet lubricants can attract contaminants.

-

Penetrating Oil

Penetrating oils are oils with low viscosity, allowing them to flow easily into tight spaces and through rust or corrosion deposits. This property makes them ideal for loosening stuck or seized fasteners. They often contain solvents like kerosene or mineral spirits, which help to reduce tension and act as carriers for the active ingredients.

Specifications and maintenance of spray lubricant and penetrating oil

There are many different types of spray lubricants and penetrating oils available, each with their own specifications.

-

PTFE Spray

PTFE spray has a variety of specifications that make it a unique lubricant. Firstly, it has an exceptionally high lubricity. This means that it can reduce friction and wear between moving parts effectively. It also has a wide operating temperature range. This allows the lubricant to remain effective in extreme heat and cold. Moreover, PTFE spray has excellent chemical resistance. As such, it will not be affected by exposure to harsh chemicals. The spray also has moisture displacement properties, making it useful in preventing electrical short circuits. It is compatible with various materials. This ranges from metals to plastics and rubber. Due to its non-toxic properties, PTFE spray is safe for use in food processing and preparation. Lastly, PTFE sprays are clear and colorless. Thus, it will not stain surfaces upon application.

-

Silicone Spray

Silicone spray lubricant has various specifications that make it suitable for different applications. It has a high viscosity index. This enables it to maintain its viscosity regardless of temperature changes. The lubricant has a wide temperature range. This means it can be used in various applications, even those with extreme temperatures. Silicone spray also has excellent water resistance. This makes it useful in applications where exposure to water occurs. It also has electrical insulating properties, making it suitable for lubricating electrical components. Additionally, silicone spray has good thermal stability, allowing it to maintain its properties even when exposed to high temperatures.

-

Oil-based lubricants

Oil-based lubricants have several specifications that make them suitable for various applications. They have a high lubricating property, allowing them to reduce friction effectively between moving parts. Oil-based lubricants also have a good film strength. As such, they can provide a protective layer on surfaces. They also have excellent thermal stability, which allows them to maintain their properties when exposed to high temperatures. Furthermore, oil-based lubricants have a high flash point. This reduces the risk of fire hazards upon application. They also have good water resistance, making them useful in applications with water exposure. Due to their chemical composition, oil-based lubricants are compatible with various materials.

-

Penetrating Oil

Penetrating oil specifications make it effective for its intended purpose, which is to loosen rusted or corroded parts. The oil has a low viscosity property. This allows it to flow into tight spaces and thin gaps between surfaces easily. Penetrating oil also has a good lubricating property. This reduces friction between moving parts. Moreover, penetrating oils have fast evaporation rates, especially in penetrating oils that contain acetone. This allows them to leave behind a lubricating film on the surface. Additionally, penetrating oils have corrosion-inhibiting properties. This prevents further rusting and corrosion of metal surfaces. They also have good compatibility with various materials, including metals and plastics.

Spray lubricants and penetrating oils have various maintenance requirements that should be adhered to. Firstly, containers should be stored away from direct sunlight and heat sources. This also includes keeping them away from open flames. Lubricants and oils should also be stored in a dry and cool place. This helps to maintain their effectiveness and integrity. Users should always inspect the products for leaks, damage, or rust. They should also be disposed of appropriately according to local regulations. Additionally, the nozzles should be cleaned regularly to prevent blockages. This helps to maintain the even and accurate spray of the lubricant.

How to Choose Spray Lubricant and Penetrating Oil

-

Consider the Type of Application:

Buyers should identify the areas or components requiring lubrication or rust removal. Different applications may need specific formulations like high-temperature resistance, fast-drying properties, or water displacement.

-

Compatibility:

It is important to ensure that the components to be treated are compatible with the chosen lubricant or penetrating oil. Some oils may not be suitable for certain metals, plastics, or elastomers, leading to degradation or adverse reactions.

-

Viscosity and Consistency:

Buyers should select products with suitable viscosity and consistency for their applications. Thicker lubricants may be needed for high-load applications to stay in place, while lighter options are better for high-speed machinery. Penetrating oils should have low viscosity to flow easily into tight spaces.

-

Additives:

Buyers should consider the additives in the spray lubricant or penetrating oil. Anti-wear additives can prolong the lifespan of components, while corrosion inhibitors protect metals from rust. Extreme pressure additives are beneficial in applications with high shock loads.

-

Temperature Range:

Spray lubricants have different operating temperature ranges. Buyers should choose products suitable for the environmental conditions of their applications. Using lubricants outside the recommended temperature range can lead to lubricant breakdown or reduced performance.

-

Application Method:

Buyers should consider the application method and choose products that are convenient and suitable for them. Spray cans with precision nozzles allow for targeted application, while bulk lubricants may require pumps or dispensers.

-

Odor and Safety:

Buyers should be aware of the odor and safety aspects of spray lubricants and penetrating oils. Some products may have strong odors or be flammable. It is important to select lubricants that are safe to use and comply with regulatory standards, such as low VOC emissions.

-

Frequency of Reapplication:

Buyers should consider how often the lubricant or penetrating oil needs to be reapplied. Some products offer long-lasting effects and protection, reducing the need for frequent application. This can save time and reduce maintenance costs.

How to replace spray lubricant and penetrating oil

The process of replacing spray lubricant and penetrating oil is quite straightforward. It is essential to have all the necessary tools and materials before starting. Below are the materials needed and a step-by-step guide on how to replace spray lubricant and penetrating oil.

- Materials: New lubricant and penetrating oil.

- Tools: Clean cloth, scraper, and brush.

Step-by-step guide

- 1. Before replacing the old lubricant and penetrating oil, users should ensure that they have purchased the right product for their needs.

- 2. Wipe off any excess old lubricant and penetrating oil using a clean cloth.

- 3. Use a scraper or brush to remove any hardened residue.

- 4. Spray the area with a cleaner to remove dirt and debris, then wipe clean after a few minutes.

- 5. After cleaning, users can apply the new lubricant or penetrating oil as needed.

- 6. Ensure that the surface is covered evenly, then wipe off any excess with a clean cloth.

- 7. Once the excess has been wiped off, users should allow the product to penetrate and lubricate the surface.

- 8. They can then reassemble any disassembled parts and test the movement or functionality to ensure the proper effect has been achieved.

Q&A

Q1: Are There Any DIY Spray Lubricant Penetrating Oil Solutions?

A1: DIY solutions are not recommended because oils and fats can attract dust and debris, which may worsen the problem. Moreover, homemade remedies have not been tested for safety and efficacy. They may contain harmful ingredients or be ineffective. It is best to use store-bought spray lubricants that are proven safe and effective.

Q2: How Do Users Know When to Lubricate Their Tools or Equipment?

A2: Users should check for squeaking noises, visible rust, difficulty moving parts, or sticking components as signs that lubricant is needed. They can also refer to the manufacturer's instructions or lubrication schedule.

Q3: Can Spray Lubricant Penetrating Oil Be Used on Electrical Components?

A3: Non-conductive spray lubricants are safe for electrical components. Users should avoid products that can cause short circuits or damage sensitive parts. Always read the label and choose lubricants suitable for the application.

Q4: How Often Should One Reapply Spray Lubricant and Penetrating Oil?

A4: The frequency of reapplication depends on factors like the type of lubricant used, the environment, and the level of usage. Users should reapply when they notice reduced effectiveness or when moving parts become less smooth.

Q5: Is It Possible to Over-lubricate with Spray Lubricant and Penetrating Oil?

A5: Yes, over-lubrication can occur. This can lead to dust and dirt accumulation, which may cause components to jam. Excess lubricant can also attract debris, worsening the situation.