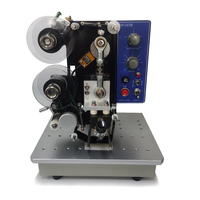

stamping coding machine

stamping coding machine

stamping coding machine

stamping coding machine

stamping coding machine

stamping coding machine

stamping coding machine

stamping coding machine

stamping coding machine

stamping coding machine

stamping coding machine

stamping coding machine

stamping coding machine

stamping coding machine

stamping coding machine

stamping coding machine

stamping coding machine

stamping coding machine

stamping coding machine

stamping coding machine

stamping coding machine

Types of stamping coding machines

A stamping coding machine comes in various types, each with unique features and advantages. The following table summarizes some of them.

- Embossing Coding Machine: An embossing coding machine uses raised metal plates to create the desired print. It operates by applying pressure to the material, which is commonly used for plastic, metal, and packaging materials. One of the advantages of an embossing coding machine is that its prints are durable and resistant to wearing off.

- Hot Stamping Coding Machine: As the name suggests, the hot stamping coding machine uses heat to transfer ink to the desired material. It works by heating up a stamped plate or die that has been coated with foil. The die is then pressed against the substrate, causing the foil to adhere to it through heat and pressure. This type of coding machine is easy to use and very flexible in changing the prints.

- Mechanical Stamping Coding Machines: Operated manually using a handle, the mechanical stamping coding machines imprint characters onto a surface by striking by the force produced from the handle's motion. They are available in various sizes and configurations. Some have different sets of characters, including numbers and letters. A typical example of a mechanical stamping coding machine is a date and number stamp. One of the advantages of this type of machine is that it provides a cost-effective solution.

- Pneumatic Stamping Coding Machines: These machines use air pressure to create prints. They are capable of producing high-quality prints on various surfaces. Unlike their mechanical counterparts, a pneumatic stamping coding machine is less tedious and requires little to no operation.

- Rotary Stamping Coding Machines: Often used in large-scale production settings, rotary stamping coding machines imprint designs onto a substrate by rotating cylinders that have the desired design engraved on them. The cylinder is then pressed against the substrate under even pressure to create a clear imprint.

Specification and maintenance of stamping coding machines

Specification

- Print area: This machine has multiple print areas depending upon the stamp design. The typical print area consists of 3 to 4 lines, and it could vary upon the need of a specific situation.

- Print medium: The coding machine usually works with various print mediums, including ink, foils, and cartridges. The kind of coding machine determines the type and size of the cartridge or foil.

- Power supply: The machine is usually available with a low power supply operating on a 12-volt battery. This allows the machine to work at a low energy usage and gives sustainable coding solutions.

- Portable stamp size: The portable stampers are available in various sizes for stamps like the mini metal stamp, mini stamp device, mini handheld stamp, etc. The size depends upon what the business chooses to code. It can be anything, including date, batch number, barcode, etc.

- Voltage: The voltage of the machine usually ranges from 100 V to 240 V. This enables the machine to work within a range of voltages.

- Print speed: The speed of the print stamping coding machine varies from model to model. It depends upon the resolution of the print. The typical speed of the machine is 300 to 600 print codes per minute.

- Coding accuracy: The accuracy of the coding in the machine may vary depending upon the type of coding the business requires. It includes anything from a simple timestamp to complex barcode stamping.

Maintenance

- Clean the machine: To clean the stamping coding machine, one should remove any dust or debris with a soft brush or lint-free cloth. It will help to prevent the clogging of ink cartridges.

- Regular ink cartridge replacement is a must: It ensures clear and crisp printing. When replacing the cartridges, one must follow the manufacturer's instructions carefully.

- Update the software regularly: The stamping coding machines have software controls that are usually required to be updated now and then. The software is firmware must be updated to ensure the coding accuracy and reliability of the machine.

- Lubricate moving parts: Moving parts of the machine should be lightly oiled or lubricated after cleaning. Doing this will ensure smooth operation and minimal wear and tear over time.

- Keep records: A good way to ensure proper functioning is to keep records of the stamping coding machine's maintenance tasks.

Scenarios of stamping coding machines

Stamp coding machines are used in various industries, such as packaging, food, manufacturing, customs, courts, and administration. The following are common industries and applications where stamping machines are beneficial.

- Product Packaging: An inkless coding machine used to print expiry dates on food items, batching info on industrial products, and barcodes, manufacturing dates, and other information on product packaging.

- Food Industry: In the food industry, a stamping machine prints labels, notices, and other information on food packaging. It ensures that the food industry complies with labeling regulations.

- Manufacturing: A die-stamping machine is used in the automotive industry and electronics industry to identify and code parts, components, and assemblies. It enables easy tracking, quality control, and inventory management.

- Customs and Courts: Customs and court authorities use stamping machines to mark documents, exhibits, or evidence with official seals or insignias. It enhances authenticity, integrity, and security.

- Transport Industry: In the transport industry, stamping machines are used to print vehicle identification numbers (VINs), license plate numbers, or labels on automotive parts for tracking and registration purposes.

- Textiles and Apparel: In the textile and apparel industry, stamping machines print logos, brand names, or product information on garments, labels, or tags. It promotes brand visibility and product authenticity.

- Construction and Registration: In the construction industry, a stamping machine marks pipes, ducts, and other components for easy identification during assembly and installation. Registration involves labeling equipment, tools, or assets with a stamping machine for inventory management and tracking.

- Healthcare and Pharmaceuticals: In the healthcare and pharmaceuticals sector, a stamping machine prints labels on medication bottles, prescription containers, or medical devices. It ensures proper medication management and compliance with regulatory standards.

- Logistics and Warehousing: At logistics and warehousing facilities, stamping machines print labels for shipment boxes, cargo containers, or storage bins. Stamping machines enhance efficiency and accuracy in inventory control and order fulfillment.

- Advertising and Marketing: Some stamping machines are used in advertising and marketing campaigns to create personalized messages, promotions, or invitations. It allows for targeted and customized marketing strategies.

How to choose a proper stamping coding machine

The first thing businesses need to do when choosing a stamping coding machine for sale is to understand their specific requirements in detail. They should take the time to list their needs and prioritize their most important requirements. This includes identifying the types of materials they plan to use the stamping machine on, the maximum size and complexity of the codes they need to stamp, and any specific features or capabilities they require.

Next, it is crucial to research various stamping coding machine types and technologies available in the market. As highlighted previously, these include roll stamping machines, hot foil stamping machines, laser stamping coding machines, and others. Compare their advantages, limitations, and suitability for distinct applications to select the type that best matches business needs.

When choosing a stamping coding machine, businesses should consider the compatibility of the machine with their materials. Different stamping machines work better with distinct materials. For instance, an ink stamping machine may not effectively code certain surfaces without proper ink formulation. Additionally, the machine's stamping area must accommodate the size and layout of the item being stamped. Consideration should also be given to the placement and accessibility of the stamping area, especially for machines integrated into production lines.

Operations and maintenance costs are crucial for businesses to consider. Choose a stamping coding machine that is user-friendly. Moreover, machines that offer quick setup and changeover times can help reduce downtime and improve operational efficiency. It may also be helpful to choose a stamping machine that is easy to maintain and clean, as this can help ensure consistent performance and reduce the risk of equipment failures. Moreover, businesses should consider the availability of replacement parts for their stamping machine in case of unexpected failures or damage.

Finally, if uncertain about the choice of the stamping machine to go for, it may be helpful to seek expert guidance. Consider consulting with professionals in coding and marking equipment who can offer valuable insights and recommendations based on specific needs. Businesses may also consider visiting facilities that use different types of stamping coding machines to gain Practical insights into the performance and suitability of various machines.

Q&A

Q1: What materials can a metal stamping coding machine work with?

A1: Generally, these machines work well with various metals. This includes soft metal materials like aluminum, copper, and brass or harder metals like stainless steel, alloy steel, and carbon steel.

Q2: Can a stamping coding machine change its designs as business needs change?

A2: Yes. Many modern machines allow businesses to make changes quickly and easily to meet different product requirements or upcoming trends.

Q3: How does the durability of a stamped item compare with other marking methods?

A3: Stamped items are very strong and can withstand wear and tear better than those marked by painting or engraving. This makes them a good choice for tough jobs where longevity is important.

Q4: Do stamping coding machines require special training for their operators?

A4: While basic operational skills can be learned easily, safety precautions and routine maintenance knowledge may demand formal technical training classes in contract with supplier services.

Q5: What is the effect of machine speed on production efficiency?

A5: The faster a metal stamping machine runs, the more items it makes per hour, improving production efficiency. However, durability, part quality, and operator safety are more important than speed.