steel plate

steel plate

steel plate

steel plate

steel plate

steel plate

steel plate

steel plate

steel plate

steel plate

steel plate

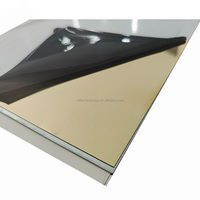

Quality Stainless Steel Sheet Supplier 0.2Mm 4Mm 201 202 304 316 430 904L 2101 Stainless Steel Plate

steel plate

steel plate

steel plate

steel plate

steel plate

steel plate

steel plate

steel plate

steel plate

steel plate

A steel plate is a flat steel sheet frequently used for fabrication, manufacturing, building, and structural applications across various sectors. It is a versatile and durable material made from carbon steel or alloy steel, with different grades and thicknesses available to suit specific applications. The steel plate is produced through a process of hot rolling or cold rolling, resulting in a smooth and flat surface with precise dimensions and properties.

Types of steel plates

First, a carbon steel plate is a common type of steel plate and is made primarily of iron and carbon. It is known for its strength, hardness, and weldability, making it suitable for structural applications, machinery, construction, and general fabrication. Carbon steel plate comes in different grades, such as ASTM A36, ASTM A572, and ASTM A516, each with specific properties and uses. Second, alloy steel plates contain additional alloying elements such as manganese, chromium, nickel, or molybdenum to enhance their strength, hardness, and wear resistance. Alloy steel plate is used in applications that require high strength, toughness, and resistance to abrasion, impact, or corrosion. Common alloy steel plate grades include ASTM A514, ASTM A588, and ASTM A387, among others. In addition, a stainless steel plate is a type of steel plate that can provide superior resistance to rust, oxidation, and staining. Common stainless steel plate grades include 304, 316, and 430, with varying levels of corrosion resistance and mechanical properties.

Applications of steel plates

First, the flat steel plate is used in the construction industry for building structures like skyscrapers, bridges, stadiums, and residential buildings. It provides the necessary strength, stability, and load-bearing capacity to support the structure and withstand environmental factors like wind, earthquakes, and snow loads. Second, steel plates are essential in the automotive industry for manufacturing vehicle components, chassis, frames, and body panels. High-strength steel plate is used to enhance vehicle safety, crash resistance, and fuel efficiency, making it a vital material in automotive manufacturing. In addition, steel plates are a primary material in shipbuilding for constructing ships, vessels, offshore platforms, and marine structures. Superior corrosion resistance, toughness, and weldability are provided by marine-grade steel plates, which can survive hostile marine environments and guarantee the dependability and safety of maritime operations. Finally, the steel plate is utilized in the energy sector for constructing power plants, pipelines, storage tanks, and support structures for energy production and distribution systems. It plays an important role in the gas industry, renewable energy projects, and power generation facilities where strength, reliability, and safety are paramount.

Aluminum plates vs stainless steel plates

First, the strength of the aluminum plate is typically not as good as that of the stainless steel plate, and it is only one-third of the strength of the stainless steel plate under the same conditions. It is also the main reason why aircraft are dominated by aluminum sheets. Second, corrosion performance is different. A stainless steel plate is composed of iron, chromium, nickel, copper, and other elements. Adding chromium elements can provide good corrosion resistance. Also, since it is non-porous, the corrosion resistance of the stainless steel material is improved. Aluminum plates have high oxidation and corrosion resistance, mainly because of their passivation layer. After the aluminum plate is oxidized, its surface will also turn white. But in some extremely acidic environments, aluminum can corrode rapidly, with catastrophic consequences.