steel railroad rails

steel railroad rails

steel railroad rails

steel railroad rails

steel railroad rails

steel railroad rails

steel railroad rails

steel railroad rails

steel railroad rails

steel railroad rails

steel railroad rails

steel railroad rails

steel railroad rails

steel railroad rails

steel railroad rails

steel railroad rails

steel railroad rails

steel railroad rails

steel railroad rails

steel railroad rails

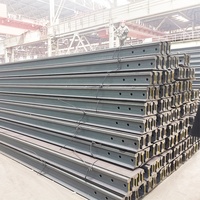

Types of Steel Railroad Rails

Steel railroad rails are long bars that form the tracks on which trains run. They are a crucial part of the railway infrastructure. Steel railroad tracks consist of two steel rails that are parallel and a railroad tie that is perpendicular to the steel rails and the track bed. The type of steel railroad track varies depending on the design.

-

Flat-bottomed steel railroad track:

These tracks rest on the ground and are secured with spikes or track nails. They are the most common type of track and are used in the United States and many other countries. This type of steel railroad track has several advantages, such as reduced maintenance costs and fast construction times. Flat-bottomed steel railroad tracks can also be used for heavy freight traffic and high-speed passenger trains.

-

Ballasted steel railroad tracks:

This type of track consists of steel rails supported by crushed stones or concrete blocks. The ballast provides stability and allows for flexibility in the alignment of the rails. Ballasted steel railroad tracks are commonly used for high-speed trains and heavy freight traffic. This is because the ballast absorbs vibrations and reduces noise, making it ideal for high-speed trains.

-

Broad gauge steel railroad tracks:

Steel rails used in broad gauge tracks are spaced wider than standard gauges. Trains that run on broad gauges offer better stability and a smoother ride. However, broad gauge tracks are more expensive to construct and maintain compared to other types of steel railroad tracks.

-

Narrow gauge tracks:

These types of steel railroad tracks have a rail gauge that is less than the standard gauge. As a result, they are less expensive to construct and maintain. Narrow gauge tracks are best suited for mountainous areas and are used in countries with low population densities.

-

Continuous welded rail (CWR):

CWR is a type of steel railroad track where long sections of rail are welded together to form a continuous ribbon. This eliminates the need for joints and provides a smoother ride for passengers. Additionally, CWR improves the speed and efficiency of freight trains by reducing rolling resistance. CWR is commonly used for high-speed passenger trains and freight trains carrying heavy loads.

Specifications and Maintenance of Steel Railroad Rails

-

Rail Profile

The rail profile is an essential specification as it influences the railroad's operation and safety. There are different profile shapes, such as the UIC60, which is the most commonly used one. It has a weight of 60 kg/m.

-

Rail Length

The rails are manufactured in various lengths, with standard lengths measuring between 12 and 25 meters. Longer rails improve ride quality and reduce maintenance needs.

-

Rail Weight

The weight of the steel railroad rails typically ranges from 30 to 80 kg per meter. Heavier rails are more durable and suitable for high-speed trains.

-

Rail Material

The most common material used for rail construction is steel. However, other materials such as manganese and alloys are also used for specific applications. Alloyed materials offer improved wear resistance and strength.

-

Rail Hardness

The hardness of steel railroad tracks is measured using the Rockwell scale. The hardness level usually ranges from 260 to 320 HRB. Harder rails have better wear resistance.

-

Rail Geometry

The geometry of the steel railroad rails, such as cant and superelevation, is also an important specification. These features affect train stability and safety.

-

Rail Joint Type

The type of joint used to connect the rails is also a specification. The most common joint type is the bolted joint, although welded joints are also used in some cases. Each joint type has its advantages and disadvantages in terms of strength and maintainability.

-

Rail Fastening System

This system is used to secure the rails to the sleepers. It consists of clips, bolts, and pads. The fastening systems must be reliable and durable to ensure rail stability.

-

Rail Wear Tolerance

Steel railroad tracks have specific wear limits. Rails are regularly inspected to ensure they meet the specified wear tolerance. This helps prevent safety issues caused by worn-out rails.

-

Electrical Conductivity

The rails also serve as a conductor for signaling and communication systems. Therefore, they must meet the required electrical conductivity standards to ensure reliable operation of these systems.

-

Quality Assurance Standards

The steel railroad tracks must comply with international standards such as ASTM and EN. These standards ensure that the quality and performance of the rails meet the requirements of the railroad industry.

-

Environmental Resistance

The steel railroad tracks should be able to withstand various environmental factors such as corrosion from moisture and chemical pollutants. Therefore, the rails need to have anti-corrosion properties and be resistant to environmental damage.

Maintenance of railroad tracks is essential for smooth and safe train operations. Key maintenance activities include:

- 1. Regular inspections are done to monitor the condition of the railroad tracks and identify any problems, such as rail wear or cracks.

- 2. Track geometry is maintained by adjusting the alignment and level of the track to ensure trains run smoothly and safely.

- 3. Vegetation control is done to remove plants and trees near the track to prevent obstacles and damage to the railroad track.

- 4. Drainage systems are maintained to ensure rainwater and floods do not damage the railroad tracks by removing excess water from the area.

- 5. Rail welding and grinding is done to repair rail joints and restore rail profiles, thereby reducing wear and improving rail stability.

- 6. Ballast maintenance involves replacing and leveling the ballast to ensure the stability and support of the railroad tracks.

- 7. Signaling and communication systems are maintained to ensure train operation safety and coordination through reliable signaling and communication.

- 8. Preventive maintenance is carried out to reduce the likelihood of failures and accidents through regular inspection and maintenance of critical components of the railroad system.

How to Choose Steel Railroad Rails

Wholesale buyers need to consider the following factors when purchasing steel railroad rails:

-

Type of rail

Buyers should choose the type of rail that fits the purpose of the railway. For high-speed trains, heavy-duty rails are needed. In cities where there is a lot of traffic, tracks that can handle frequent stops and starts are best. Rural areas can use lighter tracks because there is less traffic. Rails with good sound and vibration dampening are important in places like cities where noise and bumps need to be reduced.

-

Quality of steel

Buyers should get rails made from high-quality steel. The steel should have the right balance of strength and flexibility. It needs to be strong enough to handle heavy loads without breaking. The steel's chemical composition is key - there should not be too much or too little of certain elements like carbon. Quality control processes during production ensure consistent properties in the finished rails.

-

Size and weight of rails

Steel railroad tracks come in different sizes and weights. Heavier tracks last longer and provide a smoother ride, but they cost more and are harder to install. Buyers should consider budgets and maintenance capabilities when choosing rail size and weight. Thicker ties improve stability but increase costs.

-

Joint and fastening systems

Buyers should select suitable methods for connecting rails and securing them to the ground. These joints and fasteners need to be dependable for the railway's duration. The chosen systems should allow for expansion and contraction due to temperature changes.

-

Maintenance requirements

Some tracks need more maintenance than others. Buyers should think about how much work and money they want to spend on upkeep. Lighter rails are cheaper but require more frequent maintenance. The chosen rail and fastening systems should allow for expansion and contraction due to temperature changes.

-

Environmental conditions

Buyers must consider factors such as temperature, humidity, and corrosion in their location. Rails with coatings or treatment can withstand harsh environments. In coastal areas, corrosion-resistant materials are vital.

-

Budget and financing options

Setting a budget is essential when buying steel railroad tracks. In the long run, heavier rails may be more cost-effective, even if they are more expensive initially. Buyers can look into financing methods to afford the budget.

-

Supplier reputation and experience

It is important to buy tracks from trusted makers with a record of high-quality materials and service. Buyers should check out reviews and talk to other customers to see how happy they are. Experienced suppliers can help with choosing rails and putting them in.

How to DIY and Replace Steel Railroad Rails

There are several steps involved in replacing railroad tracks. First, the proper tools must be collected, and these include the following:

- New rail sections

- Fishplates

- Bolts

- Wrenches

- Rail jacks

- Track gauge

- Rail saw

- Personal protective equipment

Once the tools are ready, the process begins as follows:

- Safety Precautions: To begin with, ensure that all safety precautions are in place before attempting any railroad track work. This entails donning the necessary safety gear, such as a safety helmet, steel-toed boots, and high-visibility clothing.

- Prepare the Work Area: Next, clear the area of any debris or obstacles that could pose a risk to the workers. In addition, ensure that there is adequate lighting and ventilation in the area where the work will be carried out.

- Remove Old Rail: Start by using a rail saw to cut the old rail into manageable sections. After that, use rail jacks to lift the rail sections off the track bed and remove them from the work area.

- Prepare the Track Bed: After the old rail has been removed, clean the track bed of any debris or vegetation. In addition, ensure that the track bed is level and properly compacted before installing the new rail.

- Install New Rail: Position the new rail sections on the track bed and align them using a track gauge. After that, secure the rail sections to the track bed using rail spikes or bolts.

- Join Rail Sections: To join the rail sections, use fishplates and bolts to connect adjacent rails. Make sure the joints are properly aligned and tightened to prevent any movement or displacement of the rail.

Once the rail sections are joined, inspect the joints for any signs of wear or damage. Replace any worn or damaged fishplates or bolts as necessary.

- Test the Track: Before reopening the track for train operations, conduct a test run using a maintenance-of-way vehicle. This will help identify any issues with the track alignment or rail joints that need to be addressed before regular train operations can resume.

Q and A

Q1: Are concrete railroad ties better than steel ties?

A1: The preference for concrete or steel ties depends on various factors. Concrete ties are more commonly used in modern high-speed and heavy-haul railroads because they are durable and require less maintenance. On the other hand, steel ties might be preferred in certain situations, such as in areas requiring more flexibility or specific load-bearing requirements. Ultimately, the choice between the two will depend on the specific needs of the railroad.

Q2: How are railroad ties manufactured?

A2: Railroad ties can be manufactured from various materials, including wood, concrete, steel, and plastic. Each material has its advantages and is selected based on various factors, including the type of railway, load requirements, environmental conditions, and budget considerations. For instance, wooden ties are traditionally used and are still widely used in many regions because of their cost-effectiveness and ease of installation. Concrete ties are increasingly popular due to their long life and low maintenance. Steel ties offer high strength and durability, particularly in heavy-haul and high-speed applications.

Q3: What is the role of rail fasteners?

A3: Rail fasteners are critical components that keep the rails securely attached to the ties. They ensure the alignment and stability of the tracks, which is vital for safe and efficient train operations. Various types of rail fasteners are available, including spikes, clips, and bolts, each designed for specific applications and track systems.

Q4: How often should track maintenance be performed?

A4: Track maintenance frequency depends on various factors, including traffic volume, speed, and environmental conditions. Generally, routine inspections and maintenance are essential to ensure safety and reliability. Preventive maintenance can help identify and address potential issues before they become critical, reducing the risk of accidents and minimizing disruptions to train operations.

Q5: What are the environmental considerations in track construction and maintenance?

A5: Environmental considerations are increasingly essential in railway projects. Measures should be taken to minimize the impact on ecosystems, wildlife, and vegetation during track construction and maintenance. Noise and vibration management are also critical, especially in urban areas. Stakeholders must comply with environmental regulations and adopt sustainable practices.