steel sheet pile

steel sheet pile

steel sheet pile

steel sheet pile

steel sheet pile

steel sheet pile

steel sheet pile

steel sheet pile

steel sheet pile

steel sheet pile

steel sheet pile

steel sheet pile

steel sheet pile

steel sheet pile

steel sheet pile

steel sheet pile

400*170 Steel Sheet Pile U/Z Customized Size Hot Rolled Carbon Steel Sheet Pile with Customized Size

steel sheet pile

steel sheet pile

steel sheet pile

steel sheet pile

steel sheet pile

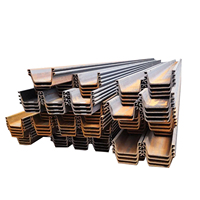

Types of Steel Sheet Pile

Steel sheet piling is available in several types. They include:

-

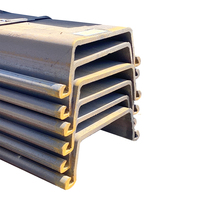

Larssen Interlocking Piles

This type features a unique interlocking design, allowing edges to form a secure connection with adjacent piles. The locking mechanism ensures effective soil retention and water dividers, making it ideal for steady groundwork in ports, docks, and coastlines. Easily installable, it requires minimal excavation, often used in restricted areas where limited access exists.

-

Z-section Steel Sheet Piles

Z-piles have a distinctive z-shaped cross-section that provides strong structural support. The geometry allows one side of the pile to overlap the adjoining one, creating a very rigid and stable configuration. It is commonly used in bulkheads, retaining walls, and deep excavations due to its high moment resistance and load-carrying capacity.

-

U-section Steel Sheet Piles

The U-shaped design provides a simple, easy-to-handle interlocking system. It is used in various applications, including earth retention and water control. Its straightforward design allows for quick installation and can be reused in multiple projects, making it economical for short-term and some permanent structures.

-

F-type Steel Sheet Piles

This type integrates a flange along the edges of the pile, increasing the interlock's surface area and improving connection strength. It combines the benefits of U and Z profiles, offering good resistance to bending. Often employed in marine structures, it is suitable for areas with heavy loading and wave action.

-

Alternative Steel Sheet Piles

Besides the specific types, steel sheet piles can be made in custom profiles. For example, they can be designed with variations in thickness or length to meet specific engineering needs. These customized piles may be necessary for particular projects demanding unique solutions to soil conditions, load requirements, or environmental factors. Advancements in manufacturing also allow for the development of more complex profiles to enhance structural performance.

Features of Steel Sheet Pile

Steel sheet pile walls feature several characteristics. They include:

-

Corrosion Resistance

Sheet piles are made of steel alloys. Some of the steel is added to enhance the corrosion resistance of the sheets. Additionally, they are often coated with protective materials such as galvanization, paint, or epoxy to further increase their lifespan in corrosive environments. Piles for marine applications typically have high resistance to saltwater corrosion.

-

Flexibility and Versatility

Steel sheet piles are manufactured in various profiles and lengths, making them adjustable for diverse engineering needs. They can be bent into curves or driven at different angles. This flexibility enables their use in straight and circular cofferdams, seawalls, and containment structures. Moreover, their reusable nature contributes to cost-effectiveness across projects.

-

Durability and Strength

Usually, steel sheet piles are constructed using high-strength steel, which offers superior load-bearing capacity. This makes them useful for deep excavations and heavy lateral earth pressures. In terms of durability, Piles are built to withstand extreme weather, seismic activity, and other environmental conditions, securing long-term structural integrity.

-

Lightweight and Easy Installation

Compared to concrete alternatives, steel sheet piles are lightweight. This allows for easier handling and transportation to construction sites. It also minimizes the equipment requirements during installation. Additionally, their design permits interlocking, enabling quick assembly driving them into the ground using vibratory or hydraulic pile drivers.

-

Cost-effective

Steel sheet piles are cheaper when carrying out construction work since they require less excavation and dewatering. Moreover, their reusability reduces the time needed for installation, further lowering labor costs. In the long run, their durability reduces the need for frequent repairs or replacements. This makes them very budget-friendly for earth retention and waterfront structures.

Uses of Steel Sheet Pile

Steel sheet piling has many uses. They include:

-

Waterfront Construction

Steel sheet piling creates strong and lasting walls for piers and wharves. It bears heavy loads and defends against erosion and wave force. Moreover, it gives a solid base for trucks and boats, improving safety and stability. As such, it simplifies the movement of materials and enhances the overall functionality of marine facilities.

-

Excavation Support

In deep digging, steel sheet piles hold back soil and lessen lateral pressure on surrounding walls. They prevent cave-ins, assuring laborer safety. Also, by providing stable support, they allow businesses to carry out underground work like plumbing and wiring. This enables multiple underground structures to be constructed without collapsing into each other.

-

Flood Protection

Usually, steel sheet piles construct barriers like levees and flood walls to protect against high water. Their strength withstands pressure from surging rivers and seas, lowering the danger of property damage. In addition, the piles enable communities to stay in high-risk areas for flooding by securing homes and infrastructure from water invasion.

-

Retaining Walls

Steel sheet piles are preferred for holding back soil in slopes and embankments. They provide attractive and durable solutions for land stabilization. Also, they effectively manage the lateral force of the earth, preventing slippage or shifting. In landscape design, they integrate well, offering greener alternatives as planters for vegetation along retaining structures.

-

Industrial Applications

In industrial settings, steel sheet piling creates barriers or dividers. This protects work areas and machine compartments from flooding or unwanted intrusion. It’s robust and resistant to chemicals and water, making it useful in factories near water or with high moisture levels. Additionally, they help organize space by separating different industrial activities.

How to Choose Steel Sheet Pile

When choosing steel sheet piling for sale, wholesale buyers should consider certain factors. Here are some of them:

Specific Application

Buyers should determine the specific use of steel sheet piling. Should it be used for retaining walls, foundation support, or coastal defenses? The type of steel sheet piling should be determined by the type of project. For instance, z pile sheets are ideal for heavy-duty projects while u pile sheets are ideal for light-duty projects.

Soil and Water Conditions

Buyers should analyze the type of soil and water conditions where the steel sheet piling will be installed. The conditions include soil composition, water levels, and tidal movements. Buyers also need to consider the corrosion resistance of the steel sheet piling. Such factors will help determine the necessary thickness and the appropriate materials required.

Interlock Design

Usually, steel sheet piling designs come with various interlocking mechanisms. The mechanisms work differently in terms of ease of installation and strength. Buyers can also find steel sheet piling with customized interlocking designs. Buyers should select an interlocking design that suits the equipment available to the contractors in the region.

Load Requirements

Buyers should evaluate the project’s load-bearing requirements. Some of the requirements include hydrostatic pressure and soil lateral loads. Such requirements will affect the choice of profile and thickness of a single sheet of piling.

Profile Type

Buyers should determine the profile type that meets the project requirements. There are multiple variations of steel sheet piling profiles. Each of them offers unique advantages. For instance, U-shaped profiles are easy to install. At the same time, Z-shaped profiles provide high strength. Buyers can choose between F and ω profiles which are designed for specialized applications.

Q&A

What is the difference between steel sheet piling and others steel?

Steel sheet piling is mainly used in construction projects involving excavation support, flood control, and shoreline protection. Other steel types like beam steel are used in structures that require horizontal supports.

Do steel sheet piling have any effect on the environment?

Usually, steel sheet piling has an impact on surrounding ecosystems. This is mainly when used for shoreline protection. In such a case, they affect tidal movements. Therefore, disturbing marine life found in the area. Buyers can mitigate this effect by incorporating design elements that allow for better ecological interaction.

What makes steel sheet piling suitable for various construction projects?

Steel sheet piling is suitable for various construction projects due to its strength, flexibility, and resistance to water and soil corrosion. Its ability to withstand lateral forces and create watertight barriers makes it valuable for retaining walls, cofferdams, and waterfront structures.

What maintenance practices should be carried out to extend the lifespan of steel sheet piling?

Normally, maintenance practices like periodic inspection for corrosion and mechanical damage are required. In addition, the application of protective coatings, such as galvanization or corrosion-resistant paint, should be done. Furthermore, regular cleaning to remove debris and facilitate drainage will prevent moisture accumulation.