stone machine

stone machine

stone machine

stone machine

stone machine

stone machine

stone machine

stone machine

stone machine

stone machine

stone machine

stone machine

Top Soil Screener Mobile Compost Drum Screen Small Stone Sieve Machine for Sawdust Wood Chips Refuse

stone machine

stone machine

stone machine

stone machine

stone machine

stone machine

stone machine

stone machine

stone machine

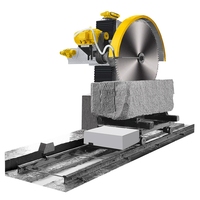

Types of stone machines

There are many types of stone machines for carrying out various tasks like cutting, polishing, and engraving stones. Some commonly used stone machines include:

- Stone cutting machine: A stone cutting machine, also known as a stone cutter, is simply a power tool used for cutting stone materials. Stone cutting machines are often suitable for cutting materials like marble, granite, quartzite, sandstone, etc. The most common types of stone cutting machines are block cutters and bridge saws. A block cutter for marble is an effective tool used to cut large marble blocks into smaller slabs for further processing.

- Stone engraving machine: Stone engraving machines make designs on stone materials by etching patterns into the surface of the stone. These machines permanently make such inscriptions and are popularly used to create memorial leaves, tombstones, plaques, and ornaments. CNC machines are currently the most popular types of stone engraving machines.

- Stone polishing machine: As the name implies, stone polishing machines are machines used to polish stones. Such machines ensure that the final stone product has a durable and shiny surface. Various types of stone polishing machines are available on the market including flat polishing machines, automatic polishing machines, and manual polishing machines among others.

- Stone drilling machine: Stone drilling machines make accurate holes into stone materials. These holes are usually made when there is a need for anchors, taps, and fittings as well as in the case of geological exploration. Diamond drill presses are one of the most popular types of drilling machines for stones. This is because they offer accuracy and control when making holes in difficult rocks.

Stone machine specification and maintenance

The specification of a stone-cutting machine will depend on the particular type of machine in question. However, some common specifications are as follows.

-

Applicable material

A stone-cutting machine is designed to cut various types of stones. However, some machines are better suited for specific types of stones than others. For example, a diamond wire saw machine is suitable for cutting hard and abrasive materials like granite, marble, quartzite, and sandstone.

-

Cutting method

Different types of cutting machines will adopt various cutting methods, such as blade cutting, wire cutting, water jet cutting, laser cutting, etc. For example, a stone cutting machine with a water reservoir uses the blade method.

-

Cutting thickness and width

A stone-cutting machine is generally used to cut stones of specific thicknesses and widths. For example, the slabs produced using a stone machine range from 10MM to 100 MM thickness, depending on the end user's needs. The machine can produce blocks, slabs, or just finished products like steps, coping, and classical columns.

-

Cutting Accuracy

When considering a stone machine for sale, owners will need to think about the required precision. The cutting accuracy of a stone machine varies depending on the design, functionality, and purpose of the machine. For instance, a wire stone cutting machine may achieve an accuracy of ±0.5mm, while a CNC stone cutting machine may have a precision of ±0.1mm.

-

Motor Power

A stone machine's motor power will depend on the type of machine and its cutting method. For example, a stone cutting with an integral motor can have 20HP or more.

With such variations in specifications, it is necessary to know that each machine needs some care and attention. Some basic steps can be taken for routine maintenance of stone-cutting machines:

- Before using any stone-cutting machine, it should be thoroughly inspected. All parts should be checked for wear and tear, as well as any damage that might have been caused during transport or storage.

- The machine will have many movable parts, all of which need lubrication to function well and have a long life. Parts like bearings, chains, slide rails, pulleys, and gears, to name a few, should be oiled or greased, as instructed by the manufacturer, on a regular basis.

- Cleaning is an integral part of maintenance. Dust and debris accumulated from operating the machine should be promptly removed. This is especially true for any blockages near the motor exhaust area, which should be cleaned to prevent overheating.

- A stone cutting machine will have some replaceable parts, like blades, wires, and belts, that may need to be replaced from time to time to ensure cutting accuracy and quality. Manufacturers offer invaluable support in deciding which parts to replace.

Usage scenarios of stone machines

- Stone mining and quarrying: In quarries, stone-cutting machines are used to mine and cut raw stones. They are used to trim the shape of stones and make them to reach the desired size and shape for use in construction projects.

- Stone processing: Stone machines are widely used in stone processing factories. For example, stone cutting machines can cut stone materials into slabs, strips, blocks, etc., while stone polishing machines can polish the surface of stone materials to make them smooth and shiny.

- Construction projects: In various construction projects, stone machines are used to process stone materials to meet project requirements. For example, stone cutting machines can cut marble, granite, etc. into floors, wall panels, countertops, etc. Stone engraving machines can engrave patterns and designs on stone materials to make decorative elements such as engravings, statues, etc.

- Landscaping and indoor decoration: Stone machines also have important applications in landscaping and indoor decoration. For example, stone engraving machines can carve beautiful patterns and designs on stone materials for landscaping use. Moreover, stone polishing machines can be used to make polishing products such as countertops, tabletops, and 台.便.最终 ,使室内和户外空间看起来更优雅和迷人.

- Other specialized fields: Stone machines also have specialized applications in some specialized fields. For example, stone engraving machines can engrave characters, patterns, etc. on tombstones for the funeral industry. Moreover, stone drilling machines can drill holes in stone for installing pipelines, wires, etc. The stone grinding machine can grind and polish rough surfaces of stone to achieve a smoother finish.

How to choose stone machines

Choosing the right stone machine involves considering various factors. Here are some things to look at when picking up a stone-crafting machine:

-

Project requirements

Before purchasing, buyers should identify their stone machining needs and compare them with the existing available options. They should analyze their project's specific requirements, such as the desired shape, size, and level of precision, and the type of stone material. Buyers should also consider their workflow and production capacity needs. Once all this has been reviewed, it will be easy to match the needs of the project to the capabilities of the stone machine and choose a suitable machine.

-

Quality and durability

It is important to purchase a stone machine with high quality and durability. A good quality stone machine will have a stable structure, strong cutting components, accurate control systems, and efficient dust extraction mechanisms. Such machines are more precise and easier to control, thus improving the operator's overall experience. They can also handle different types of stone materials without wearing off. A durable stone machine will require less maintenance and can easily handle daily wear and tear. It has reliable parts fitted into it that fulfill their functions perfectly.

-

Budget and cost efficiency

Budget plays a huge role in determining the kind of stone machine one ends up with. Knowing the budget helps narrow down the options, making it easier to choose. A favorable feature many buyers look for in a stone machine is cost efficiency. Good machines help to minimize material waste while maintaining energy efficiency. This goes a long way in reducing operational costs.

-

Ease of use and automation

Consider a stone machine's user-friendliness and automated options when purchasing. Machines with automated and efficient operational functions can boost productivity and reduce skill level requirements. Features such as CNC (computerized numerical control) capabilities, intuitive controls, and user-friendly interfaces make these machines easy to use. Automated functions help to streamline workflows and allow for longer, uninterrupted machining operations.

Q & A

Q1: What are the latest trends in stone cutting machine technology?

A1: Recent trends in stone cutting machines show an increase in automated cutting machines, CAD/CAM integration, and laser technology.

Q2: What is the lifespan of a stone engraving machine?

A2: A well-maintained stone engraving machine can last for 10 to 15 years or even longer with proper maintenance and timely repairs.

Q3: Can a stone engraving machine be used for materials other than stone?

A3: Typically, a stone engraving machine is made to engrave stone materials. However, some may be able to engrave other materials like metal, plastic, or wood: depending on the machine and its capabilities.

Q4: What are the most effective ways to market stone engraving machines?

A4: To market stone engraving machines, one can consider attending trade shows and exhibitions, online marketing strategies such as SEO, PPC, content marketing, and social media, direct mail and email marketing, and joint ventures and partnerships.