syringe assembly machine

syringe assembly machine

syringe assembly machine

syringe assembly machine

syringe assembly machine

syringe assembly machine

syringe assembly machine

syringe assembly machine

syringe assembly machine

syringe assembly machine

syringe assembly machine

syringe assembly machine

syringe assembly machine

syringe assembly machine

syringe assembly machine

syringe assembly machine

syringe assembly machine

syringe assembly machine

syringe assembly machine

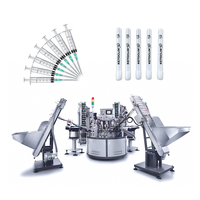

2024-2 Zhejiang Huanchou Machinery Syringe Making Machine with Safety Cover Syringe Assembly Machine

syringe assembly machine

Types of Syringe Assembly Machines

The syringe assembly machine is an essential piece of equipment in the medical field. Therefore, it is not surprising that there are different models and types of machines to assemble syringes. Some of the machines may work with multiple medical devices besides the syringe. Below are some of the popular types of syringe assembly machines:

-

Fully Automated Syringe Assembly Machine

This fully automated assembly machine is a standalone unit that completely assembles a medical syringe from its individual parts in one assembly line. The unit may have 8-12 stations to clean, assemble, weld, fill, and cap syringes. Typically, robotic arms or automated tools insert plunger rods into the barrels of the syringes. Ultrasonic welding may be used to secure them together. Ultrasonic welding is advantageous because it does not use any additional parts or fasteners that could compromise a sterile environment.

-

Modular Assembly Machine

A modular assembly machine has interchangeable modules. Each module performs a specific task, such as cleaning, filling, capping, or assembling barrels and plunger rods. Operators can easily change the modules according to their needs. As a result, this assembly machine provides flexibility and scalability for producing syringes of different types and sizes.

-

Robotic Assembly Cells

Robotic assembly cells use advanced robots to accurately place or assemble syringe components. Vision systems identify and position the parts required. These cells are flexible and can adjust to different types of syringes with a quick change of tools and programs.

-

Manual Assembly Machine

Although rare, a manual assembly machine still permits operators to manually assemble the syringe parts. The operator puts the plunger and other components of the syringe together. This kind of assembly may be slow, and it cannot ensure the same level of accuracy or efficiency that other automatic or semi-automatic assemblies would provide.

-

Multi-Device Assembly Machines

Some manufacturers may produce an assembly machine that can make multiple devices. As an example, the machine may be able to construct syringes with other medical instruments like tubes or catheters. These assembly devices usually have quick changeovers and customized modules to adapt to the required specifications.

-

Flow Injection Assembly Machines

In this kind of assembly device, each component is manufactured in parallel. Flow-injection technology is used to combine raw materials and inject them into a specific reaction. It is a highly efficient way to create multiple complex assemblies at once, minimizing the need for continuous input and reducing time.

Specification and Maintenance

Core components of a syringe forming machine, their specifications, and maintenance needs:

-

Feeding System

Syringe assembly machines use automated or manual feeding systems to supply syringe parts to the assembly line. They can feed up to 100 parts per minute or more, depending on the machine model and type. With proper maintenance, they can operate smoothly for many years.

Maintenance Needs:

Regularly clean the feed trays and chutes to remove any debris or residue. Check for worn or damaged components and replace them as needed. Lubricate moving parts to allow for smooth and consistent part delivery. Train operators to properly load parts into the feeding system to avoid jams and slow feeding rates.

-

Assembly Mechanism

The assembly mechanism is the centerpiece of a syringe assembly machine. It precisely aligns syringe parts such as the barrel, plunger, and stopper and joins them together to form a complete syringe. This component's assembly speed and accuracy determine how quickly and effectively the whole machine can make syringes. Different assembly mechanisms have their own assembly speeds.

Maintenance Needs:

Regularly inspect, clean, and calibrate the assembly mechanism. Adjust the alignment and the joining pressure. Check fasteners and moving parts. Lubricate where needed and replace worn components. Follow the manufacturer's assembly instructions and maintain a schedule based on the number of syringes assembled daily.

-

Delivery System

Assembly machines use delivery systems to provide assembled syringes to labeling, packaging, and storage areas. Conveyors are the most common method, moving assembled syringes continuously along a set path. Some machines have the option to add automated sorting and counting systems that can sort different types of syringes and keep track of numbers as they are delivered to packaging lines.

Application scenarios of syringe assembly machines

Vaccine syndicate supplies use syringe assembly machines to syringe vaccines efficiently. The machine creates syringes that deliver the correct dosage to patients. It guarantees speedy vaccine production, essential during health outbreaks and emergencies.

Sterile environments like hospitals and laboratories require syringe assembly machines. Syringe machines create syringes with safety locks to protect medical workers from dosage errors or needle stick injuries. They improve the efficiency of medical devices in the healthcare industry.

Because precision is crucial in the pharmaceutical industry, syringe assembly machines have a vital application. They create syringes used for measuring and dispensing drugs and chemicals precisely. The machines ensure product consistency and accuracy, which is necessary to maintain quality control and compliance standards.

Research institutions rely on syringe assembly machines for experimental purposes. The machines create customized syringes with specific features for scientific experiments. They support innovation and advancement in research.

By creating syringes to deliver specific amounts, food and beverage industries use syringe assembly machines for quality control and testing. The machines help ensure accurate measurement and product consistency during food production. Syringes with different capacities are also used for sample ingestion and automated testing.

How to Choose Syringe Assembly Machines

Consider the following factors when selecting a syringe assembly machine to ensure it meets specific production needs.

-

Production Capacity

Assess the machine's production capacity. This represents the number of syringes the machine can produce within a specific time frame. Consider the maximum speed, efficiency, and whether it meets production needs. If large-scale production is the aim, opt for a machine with a higher production capacity.

-

Adaptability

Machines should be adaptable to various syringe specifications, such as size and type. This will avoid the need to purchase additional equipment for making different kinds of syringes. Moreover, the machine should also be able to easily adjust and change settings to accommodate changes in production requirements.

-

Automation and Controls

Consider the level of automation in the assembly process. Automated assembly machines can streamline operations and reduce manual intervention. Look for features such as programmable logic controllers (PLC) and user-friendly interfaces that allow for precise control and monitoring of the assembly process.

-

Quality Assurance Features

Quality is crucial in syringe production, so choosing a quality control device is essential. Look for machines with in-built inspection systems to check for assembly defects, such as misalignment, incomplete assembly, and accuracy errors. These devices can help to ensure that only well-assembled syringes are produced.

-

Training and Support

When choosing a provider for a syringe assembly machine, consider the training and support they offer. Find out if they provide on-site training for operators and maintenance staff to ensure proper handling and upkeep of the equipment. Inquire about the technical support they offer after the purchase, such as availability and response time.

-

Compliance with Standards

Verify that the assembly machine complies with international standards and regulations for syringe production. Adherence to these standards can help ensure the machine's design, manufacturing processes, and safety features.

FAQ

Q1: What are the trends affecting the syringe assembly machine market?

A1: The market is growing due to manual to automated injection devices shift. Also, more efficient manufacturing for larger production is needed.

Q2: How do syringe assembly machines contribute to sustainability in the healthcare industry?

A2: Reducing material waste and optimizing resource usage during production can improve sustainability.

Q3: Can syringe assembly machines handle different types of syringes, such as those with specialized tips or graduations?

A3: Some models can, but checking the specifications to see what kinds are compatible is necessary.

Q4: What kinds of syringes can industrial machines make?

A4: They can produce plastic medical syringes, insulin syringes, no-return syringes, intravenous syringes, and other customized ones.