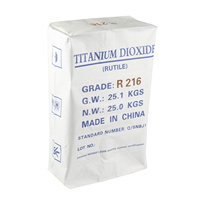

tio2 rutile

tio2 rutile

tio2 rutile

tio2 rutile

tio2 rutile

tio2 rutile

tio2 rutile

tio2 rutile

tio2 rutile

tio2 rutile

tio2 rutile

tio2 rutile

tio2 rutile

tio2 rutile

tio2 rutile

tio2 rutile

tio2 rutile

tio2 rutile

tio2 rutile

tio2 rutile

Types of TiO2 in Rutile Form

The predominant forms are anatase, rutile, and brookite. Rutile titanium dioxide, popular with its density and refractive index, appears in various regularly used product types.

Natural Rutile TiO2

This is a mineral form of titanium dioxide that occurs naturally in the earth’s crust. Commonly found in iron, it is often reddish brown as a result of iron deposits. It is used in manufacturing, gem treatment, and as colour additives.

Rutile TiO2 Pigment

This is a synthetic titanium dioxide pigment produced through processes like the sulfate and chloride methods. It is primarily used in the paint, plastics, and paper industries due to its unparalleled opacity, brightness, and ability to resist UV light.

Rutile TiO2 Nanopowder

With particle sizes in the nanometer range, this TiO2 is used for advanced technology. Its high surface area makes it relevant in catalysis, drug delivery, and environmental clean-up.

Rutile TiO2 Powder Coating

These are protective and decorative coatings without solvents that contain rutile titanium dioxide. Commonly used in heavy-duty environments, it provides superior corrosion resistance and UV degradation.

Rutile Titanium Dioxide Crystal

Originated from the mineral rutile, these pigments are used for their unique optical properties. They are often incorporated in textile and plastic applications for colour and sparkle.

Commercial Application of Rutile TiO2

Like the TiO2 anatase form, rutile TiO2 is used extensively in different industries due to its unmatched physical and chemical properties.

Pigments and Coatings

Rutile titanium dioxide is predominantly used as a white pigment in the paint and coating industry. Its ability to absorb UV light helps prevent degradation, which makes it ideal for exterior coatings, hence contributing to durability and weather resistance.

Plastics and Polymers

Titanium dioxide is commonly added into plastics to provide opacity and a barrier against UV radiation. This protects the plastic from breaking down over time. It is applied in packaging materials, automotive parts, and consumer goods.

Cosmetics

Rutile TiO2 is used in cosmetics for opacity, whiteness, and as a physical sunscreen that protects against UV rays. It is commonly found in lotions, sunscreens, and makeup products.

Paper Industry

Rutile TiO2 is used in the paper industry to improve brightness, smoothness, and printing properties. It provides a finishing touch to the paper that appeals to customers and advances colour fidelity in printed materials.

Ceramics and Glass

Due to its high melting point and chemical stability, rutile TiO2 is used in ceramics and glass applications. It improves product strength and acts as a opacifier in porcelain, tiles, and ceramic glazes.

Sun Solar Systems

Added into solar cells, the photoactivity of rutile TiO2 contributes to the efficiency of energy conversion. It helps in electron transport and improves the overall performance of the solar cell by enhancing the generation of electrical current.

Product Specification and Features of Rutile TiO2

Technical Data Sheet (TDS)

Here is a sample of a typical rutile TiO2 data sheet.

- Appearance: White powder.

- Pigment Type: Organic solvent-based.

- Crystal Structure: Rutile.

- Specific Gravity: 4.2 – 4.3 g/cm3.

- Tapped Density: 45-55 lbs per cubic foot.

- Refractive Index: 2.76-2.92.

- Moisture Content: ≤0.5%.

- Oil Absorption: 17-22 g/100g.

- Top Cut (Microns): 45.

- Composition: 99.5% TiO2.

- ASTM C 436-92: ≤0.1% Fe.

How to Install and Use Rutile TiO2

Users looking to use rutile titanium dioxide for certain applications should know the right installation process to follow. Here are key steps to ensure proper setup and usage.

- Mix Preparation: Prepare the mix by blending the rutile TiO2 pigment with other required ingredients. It could be resin and hardener in coatings or bulk titanium sponge in metal applications.

- Equipment Setup: Depending on the application, set up the required equipment. For paint or coatings, this could be spray guns, mixers, or milling equipment.

- Application Method: Apply the titanium dioxide-containing mixture using the right method. It could be spraying, brushing, or pouring. Ensure even distribution.

- Curing/Setting: Allow the mixture to cure properly. For paints, this could involve air drying. Routine checking keeps track of the process.

Maintenance and Repair of Rutile TiO2

- Storage: Store rutile TiO2 pigment in a dry, cool environment to prevent clumping and moisture absorption. Proper storage maintains the quality and longevity of the product.

- Monitoring: Keep an eye on the projects where titanium dioxide is applied to check for defects or wear. Early detection prevents these issues from becoming big problems.

- Cleaning: Clean the surroundings where the TiO2 is used to prevent the build-up of dirt or contaminants. Proper cleaning contributes to the durability of the applied layer.

- Protective Measures: Consider using protective coatings or sealants above layers containing rutile TiO2. These coatings enhance protection and contribute to quality longevity.

Quality and Safety Considerations of Rutile TiO2

How to Ensure the Right Quality

- Purity: Titanium dioxide should be at least 99.5% pure with non-relevant minerals and contaminants at less than 0.1%. Ensure it has low levels of unwanted stuff like iron and chromium that affect the quality.

- Consistency: It should be produced in a way that keeps all its properties the same. This includes size, colour, and crystal shape. Consistency matters because users want stuff that acts the same way every time they use it.

- Particle Size Distribution: There should not be wide variations in the particle sizes of titanium dioxide. Ideally, the average particle size should be around 0.3 microns for a smooth application.

- Treatment and Coating: Check if the TiO2 is coated with organic or inorganic materials. This improves how it interacts with resins and paints, which in turn improves dispersion and stability.

- Testing: Request reports from authoritative organizations that test TiO2 for toxicness and legitimacy. What to look for is certified results that confirm the product's danger-free nature and compliance with industry rules.

How to Follow Safety Guidelines

- Measure Exposure: Use proper ventilation to avoid breathing in titanium dioxide particles. When these particles enter the body via breathing, they can cause problems.

- Protect Skin: Wear stuff like gloves and protective clothing to keep TiO2 from touching the skin. The particles can irritate the skin when they touch it directly.

- Use Eye Protection: Wear goggles or a face shield to keep the particles out of the eyes. Eye exposure can cause irritation and discomfort.

- Proper Storage: Keep titanium dioxide pigment in sealed containers to prevent mix-ups and contamination. It is also necessary to keep these containers away from kids and pets.

- Care During Cleanup: Wet down ragged-up materials containing TiO2 before handling them to avoid breathing in dust. Use a vacuum with a dust filter to pick up big pieces instead of using your hands.

Q&A

How is rutile TiO2 made?

Rutile TiO2 is produced from ilmenite through a chemical process called the sulfate process. In this process, ilmenite is treated with sulfuric acid to extract titanium dioxide, which crystallizes primarily as rutile.

What are the key differences between rutile and anatase TiO2?

Rutile TiO2 is denser, more stable, and has a higher refractive index than anatase TiO2. While anatase is mainly used in self-cleaning and photocatalytic applications, rutile is preferred for pigments, coatings, and sunscreen due to its superior durability and UV light blocking capability.

What is the role of titanium dioxide in solar cells?

In solar cells, rutile TiO2 acts as a material that transports electrons. It helps in improving the efficiency of energy conversion by facilitating electron movement, thus enhancing the overall performance of the solar cell.

Is rutile TiO2 safe for cosmetics?

Rutile TiO2 is safe for use in cosmetics. It serves as an opacifier and a physical sunscreen, reflecting UV rays. It is vital to ensure that any TiO2 used in products intended for inhalation is specifically labeled as safe for that use, such as TiO2 CP (cosmetic grade).

What industries mostly use rutile TiO2?

Industries that use rutile TiO2 include paints, plastics, cosmetics, paper, ceramics, renewable energy, and pharmaceuticals. Its versatility and exceptional properties make it valuable across several realms for TiO2 applications.