tool pallet

tool pallet

tool pallet

tool pallet

tool pallet

tool pallet

tool pallet

tool pallet

tool pallet

tool pallet

tool pallet

tool pallet

tool pallet

tool pallet

tool pallet

tool pallet

tool pallet

tool pallet

Three-Layer Heavy Duty Steel Tool Trolley Durable Tool Cart with Screwdriver Pallet OEM Customizable

tool pallet

tool pallet

tool pallet

Types of Tool Pallet

Tool pallets carry different kinds of tools and tool sets used in the tools and hardware industry.

-

Fixed tool pallet

A fixed tool pallet is a stable and regular structure found in many tool storage places. It has spaces for every tool needed by workshops or production floors. In this presentation, there will be no major changes in the layout or design of a fixed tool pallet; it will always display the basic tools needed for simple work. This consistent organization helps people find tools quickly to minimize downtime during tasks.

-

Floating tool pallet

The floating tool pallet is flexible and can be moved from one place to another, unlike the fixed pallet, which is static. Floating tool pallets are used more in mobile work settings or where the workers need to change quickly to accommodate the available work. Even though it is portable, it still has space for particular items that should always be on hand. It supports the effective movement of work within different areas of a facility.

-

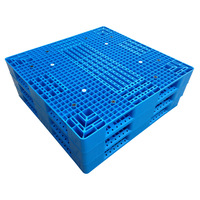

Grid tool pallet

A grid tool pallet is produced in such a form and appearance that every tool is assigned a unique position on the pallet using grid lines. This appearance frequently utilizes offered open types, which give users the benefit of easily visible and accessible equipment. The design is very helpful for trades or services that need many small instruments, as it is good for precise storage and will not mix the instruments. Usability through order satisfaction improves operation, particularly in settings that are highly dynamic.

-

Standard tool pallet

A standard tool pallet is a solution designed in accordance with uniformity principles. It is made to store commonly used instruments such as wrenches, screwdrivers, or drills. This application can be especially useful when many employees or departments have to use the same instruments. All users agree; this standardization means instruments are stored in the same way in different places, increasing accuracy when requesting an instrument.

-

Specialized tool pallet

Specialized tool pallets are used in systems where some tools need more emphasis for good system performance. However, as these tools are utilized due to their importance in given practices, they are presented on the specialized pallets well organized with the space available for each of them. Such designs better the organization and accessibility of task-specific tools. Facilities that wish to improve efficiency in some operations benefit greatly from using a specialized tool pallet.

Tool Pallet Material & Durability

Materials used in making tool pallets vary a lot due to the requirement of surrounding conditions and the expected security of tools. However, there is pertinent information about the materials that describes all the aspects of durability in tool pallets.

-

Plastic

Plastic pallets are lightweight, easy to move around, and resistant to rough handling. Most of these characteristics support their application in various operating conditions. Being resistant to chemicals also means this formation is very useful in areas where hazardous substances might affect other materials. While not as strong as wood or metal, plastic pallets give way to being strong enough for efficient storage, especially for lighter tools. In addition, their resistance to moisture ensures that the tools stay dry and hence free from rust.

-

Metal

Metal pallet construction guarantees strength and long-lasting life. Other available options are constructed using steel or aluminum and are suitable for rough handling or severe environments. In this case, metals resist cutting, bending, or wearing, so tools fitted on the metal pallet will stay secure during any task. Although this type can be more expensive, the desired endurance ensures that it is very useful in heavy operations. The anti-rust property of metals also means that this application can be used where moisture is present.

-

Wood

Wooden pallets are standard and serve as reasonable storage for tools. They are offered in larger sizes and can withstand heavyweights, which is one of their major advantages. In case of an accidental drop of a heavy tool, most likely, the impact will be absorbed by wood rather than metal. Although wood can warp and be a target for pests, the long life expected from wooden pallets in low humidity applications justifies their use.

-

Foam

The foam lining found on many tools and hardware pallets is useful because it absorbs shocks and has good organization properties. In most cases, foam is incorporated on specialized pallets for delicate instruments or those that require very high accuracy. The material allows the tools to be contained within the system, eliminating the need for tool wear or tear. Another plus of foam is that it can be customized to fit the shape of individual tools, leading to a much tighter and more secure fit. Due to the cushioning effect, packaging devices are also safe during transportation and handling.

Commercial use of Tool Pallet

Tool pallets are crucial in improving organization and effectiveness in diverse corporate settings.

-

Manufacturing

Tool pallets are applied in the production sector to ease processing. These pallets organize tools used for equipment maintenance or assembly in a production line. Having instruments close to use decreases the time for a search and speeds up the operation. Also, it helps conduct maintenance works with the necessary elimination of idle time on the machine.

-

Construction

In the construction business, building works require more tool pallets for the effectiveness of work.The pallet enables the transport of either a construction tool or a floor tool. Because it is portable, it implies that workers have all the tools required at their convenience in one area of the construction site. This application reduces wandering and boosts productivity because there are very few tools missing.

-

Aerospace

Aerospace companies benefit from this application by organizing precision tooling. There are expensive and detail-oriented instruments in this field, which are better organized using a tool pallet. These tools face a lot of damage if not handled properly. Usually, pallets protect these tools from getting lost or damaged, hence increasing their lifespan and reducing costs. Also, the influence of cost is reduced by ensuring that the tools are readily available for use.

-

Automotive

The automotive sector uses tool pallets in workshops to organize tools that are often used during repairs and servicing. Standardized and gridded-formed tool pallets are better organized and help easily identify the tools missing after use. It helps reduce the time spent searching for tools; therefore, the overall productivity increases. Further, the implementation of this helps in reducing capital cost as it takes time to locate the tool during working hours.

-

Military

In military applications, portability is crucial, and the tool pallet serves this need. Tech Pallets organize, transport, and secure delicate military gears. Specialized tool pallets are commonly applied in this context to contain unusual but typical military hardware tools. These applications reduce both the loss and damage, which might sometimes be very expensive to replace in the military venue.

How to Choose Tool Pallet

While selecting a tool pallet, factors like material robustness, flexibility, and application relevance determine its effectiveness in securely storing and protecting various tools. Below are the considerations when choosing a tool pallet.

-

Material

The material of the pallet should be chosen depending on the intended use of the pallet. Conventional materials offered for lighter and chemical-intensive applications are plastic; therefore, wood or metal is suitable for application-intensive and heavy-loads undertakings. Foam is useful for packaging instruments of higher value that need cushioning. A deep understanding of materials allows longevity and protection of the tools.

-

Weight capacity

To provide the required weight capacity, the tool pallet should house all varieties and sizes of tools. Several materials are available and are ideal for housing heavy or light tools. Choosing a pallet with sufficient load-bearing capacity prevents sagging or bending, which may harm palleted equipment.

-

Portability

Assessing whether the pallet is portable or stationary, depending on its use, is essential. Workers on-site frequently need either a strap and handle or a wheeled base to ease and move the tools around the shop. However, a standard pallet will do when the tools are housed in a stockroom.

-

Customization

Customization might be a key necessity when specialized tools should be accommodated. Pallets molded to suit the shape of certain gears or those with special dimensions for specific tool sets ensure optimum organization and security. This additional service enables choosing a pallet that will protect and display the instruments to their best advantage.

-

Environment

The surrounding conditions where the pallet will be used can also affect durability. Moisture-prone zones will call for either metal or plastic to guard against rot or rust. Conditions that involve extreme temperatures or chemical exposure will be another good reason for choosing plastic or metal, with metal being more weather resistant than average wood. Selecting a pallet appropriate for the scenario avoids breakdown early and secures tools.

Q & A

Some of the commonly asked questions about tool pallets include:

-

Q1. Which is the common material used in making tool pallets?

A1. Tool pallets are made of wood, metal, and plastic, depending on the expected strength and versatility of the intended application. Tool pallets have properties for each material; for example, wood will not harm tools like metal will, foam will absorb minor shocks, and plastics will not affect tools due to their chemical resistance properties.

-

Q2. What is the importance of a tool pallet in a manufacturing setting?

A2. Tool pallets minimize tool search time since most tools are near usage area. Tool pallets play a significant role in the automotive, construction, aerospace, and manufacturing sectors, making work easy by having the tools organized and readily accessible to use, thus preventing time wastage.

-

Q3. What factors determine the weight a tool pallet can hold?

A3. The material and design structure behind the tool pallet design heavily determine the weight capacity. Lighter and portable materials like plastics might not give the required support, while wooden or metal tool pallets might support heavy tools because of their robust construction and structure. Another supporting factor for weight capacity is the size of the pallet.

-

Q4. How can one enhance the lifespan of a tool pallet?

A4. Selecting the most appropriate material for the environment in which the tool pallet will be used will drastically improve its longevity. Maintenance-free materials like plastic and metal may serve for a longer time, and if they are exposed to an environment containing moisture, this exposure will not affect them as it will the wood material. Proper storage away from direct sunlight will also prolong the longevity of the tool pallet.