tube connector

tube connector

tube connector

tube connector

tube connector

tube connector

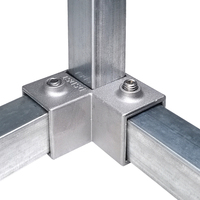

20Mm 25Mm 30Mm Adjustable 2 3 4 5 6 Way Nylon Pp Pvc Aluminium Square Tube Plastics Corner Connector

tube connector

tube connector

tube connector

tube connector

tube connector

tube connector

tube connector

tube connector

tube connector

tube connector

tube connector

tube connector

tube connector

tube connector

tube connector

Introduction to Tube Connectors

Tube connectors serve as essential components in a variety of industries, facilitating the connection of tubes and pipes for efficient fluid or gas transfer. These connectors are designed to maintain a secure and leak-proof connection, ensuring optimal performance in applications such as plumbing, pneumatic systems, and mechanical assemblies. By understanding the various types and features of tube connectors, you can select the right solution for your specific needs.

Types of Tube Connectors

Tube connectors come in several types, each catering to different requirements based on application, size, and functionality:

- Pneumatic Tube Connectors: Ideal for air and gas transfer in pneumatic systems.

- Hydraulic Tube Connectors: Designed for high-pressure applications, ensuring safe hydraulic fluid transfer.

- Plastic Tube Connectors: Lightweight and corrosion-resistant, perfect for low-pressure applications.

- Metal Tube Connectors: Durable and sturdy, suitable for high-temperature and high-pressure environments.

- Quick Disconnect Tube Connectors: Allow for easy and rapid connections, facilitating maintenance and replacement.

Function, Feature and Design of Tube Connectors

Understanding the functional aspects and design features of tube connectors is vital for selecting the right type for your projects:

- Secure Connection: Designed to provide a firm and leak-proof seal between tubes, preventing fluid loss and ensuring safety.

- Versatile Material Options: Available in materials like plastic, brass, stainless steel, and aluminum, catering to different environmental challenges.

- Easy Installation: Most tube connectors feature a simple assembly process, requiring minimal tools and technical expertise, saving time and labor costs.

- Temperature Resistance: Various designs withstand extreme temperatures, adapting to different operating conditions.

- Customizable Sizes: Available in numerous sizes and thread types, allowing compatibility with a wide range of tubing systems.

Applications of Tube Connectors

Tube connectors are employed across countless applications, providing reliable solutions in various industries:

- Automotive Industry: Used in fuel lines, coolant systems, and air intake systems.

- Manufacturing: Essential in conveyor systems and assembly line machines, ensuring efficient operations.

- Aerospace: Vital for hydraulic systems that operate under high pressure and specific environmental conditions.

- Food and Beverage: Used in piping systems that handle hot liquids and gases, requiring hygienic materials.

- Medical Equipment: Integral in the construction of various medical devices that rely on precise fluid management.

Advantages of Using Tube Connectors

Investing in high-quality tube connectors can greatly enhance operational efficiency. Here are some notable advantages:

- Cost Efficiency: High durability reduces the need for frequent replacements, minimizing costs over time.

- Enhanced Safety: Reliable connections reduce the risk of leaks and failures, ensuring a safer working environment.

- Improved Performance: Streamlined flow and pressure control enhance overall system efficiency.

- Wide Compatibility: Available in various specifications to suit different tube types and applications, promoting versatility.

- Reliable Sealing: Designed to withstand vibration and movement, maintaining integrity even in dynamic environments.