tube machine

tube machine

tube machine

tube machine

tube machine

tube machine

tube machine

tube machine

tube machine

tube machine

tube machine

tube machine

tube machine

tube machine

tube machine

tube machine

tube machine

tube machine

tube machine

tube machine

tube machine

Types of tube machines

Tubes are cylindrical objects with multiple uses in various industries. The tube machine is used to make such tubes from various materials like metal, plastic, and paper. Tube machines are designed for specific materials and product types.

-

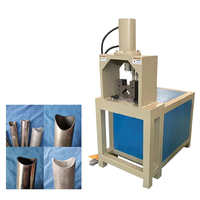

Metal Tube Making Machine:

Metal tube machines are for manufacturing metal tubes like aluminum, iron, and stainless steel. These machines form metal tubes with precision for applications like plumbing, construction, automotive, and industrial equipment. The metal tube machine has a high-degree automation and is also efficient. It has easy operations, productivity, and quality that meet the requirements of heavy industries. The devices are durable, steady, and reliable for producing metal parts in heavy volumes. The machines also have great adaptability for various product specifications. Buyers can find suitable tube machines according to their production needs.

-

Plastic Tube Making Machine:

A plastic tube machine creates plastic tubes from PVC or PP for packaging, cosmetics, or medical products. With technological advancement, plastic tube-making devices now have a variety of functions. They can produce tubes with different diameters, lengths, shapes, and printing patterns. Some machines also have multifunctional capabilities. They can produce, cut, print, and pack the tubes all in one go. Additionally, plastic tube machines are friendly to the environment. Most of them waste little material in the production process and can recycle the leftover materials. These machines also lower energy consumption and help businesses reduce costs.

-

Paper Tube Making Machine:

The paper tube machine is used for making tubes out of paper, which are biodegradable. These tubes are used for sticking boards, textile wharves, and other applications. The paper tube machine makes the production of tubes easier and more efficient. This machine creates paper tubes for various uses with high precision and at a rapid speed. Many sagacious machines are automatic, thereby reducing labor intensity. The multifunction paper tube machine integrates mandrel rotating, paper feeding, gluing, winding, cutting, and receiving into one unit. It has a higher production efficiency and can fulfill mass production needs.

Specification and maintenance of tube machines

Specification

- Machine size: Depending on the production requirement, one can choose a compact model or a large industrial tube machine. For a dedicated production line, there might be a custom tube machine with a specific width, length, and height.

- Production capacity: This is usually stated as the maximum number of tubes produced per hour. Small machines may produce around 1,000 units an hour, while larger industrial machines produce around 20,000 per hour. The actual capacity will depend on the operational efficiency and skill level of the workforce.

- Applicable Industries: The tube machine has widespread applicability in multiple sectors, including food and beverage, personal care, medicare, household products, and chemical industry.

- Tubing Materials: Tube machines are made from different materials. The food packaging tube must use material that complies with FDA regulations and is safe for food packaging. In contrast, beauty tube machines only need to meet the requirements of the cosmetic packaging industry.

- Power Source: A tube machine's power source could be hydraulic, pneumatic, electric, or a combination of these, depending on the design and purpose of the machine.

- Manufacturing Process: Tube machines manufacture different types of tubes. They might use various methods, such as electroplating, extrusion, drawing, and more.

Maintenance

Proper maintenance is crucial for the continued performance and longevity of tube machines.

- Cleaning: It's essential to clean the machine regularly and remove any tube material, adhesive, or contaminant residue. A brush, scraper, or solvent should be used to reach and clean the narrow, intricate areas thoroughly.

- Lubrication: Lubrication of mobile parts like bearings, gears, and chains is important. Grease should be applied to maintain the machine's effortless operation and avoid wear and tear. Only use high-quality lubricants, and lubricate appropriately according to the operating manual.

- Replacement of consumables: Consumable parts are frequently replaced, such as guide rings and cutting blades. These parts can affect the quality and efficiency of tube production when worn out. Regular inspection and timely replacement of these parts are crucial.

- Equipment debugging: After cleaning and replacing consumables, debug the tube machine. Check the position of each part to ensure it is in the proper place. Adjust the machine's operating parameters according to the required tube specifications to optimize performance.

- Regular maintenance; Develop a regular maintenance schedule based on tube production volume and frequency. Routine maintenance may include cleaning, lubrication, replacement of consumables, equipment debugging, etc. Regular maintenance can ensure machine stability and reduce sudden breakdowns.

- Repair and upkeep: If there is any damage or abnormality in the functioning of the tube machine, it is essential to repair it promptly and keep it up. Address any parts that are worn or damaged, and conduct a thorough inspection to ensure the machine's safe and normal operation.

Uses of tube machines

There are a variety of industry tube machine uses, which are primarily for businesses. They include the following:

- Manufacturing Industries: Tube machines are used to produce tubes and pipes in manufacturing industries. These machines cut, form, and weld materials like plastic and metal into tube shapes. For example, tube mill machines help create cylindrically closed metal pipes used in construction, automotive, and plumbing. In these industries, tube machines increase productivity and supply businesses with tube materials.

- Packaging Industries: Packaging industries use tube machines to manufacture packaging tubes. Products such as toothpaste tubes, cosmetic product tubes, and food product tubes are made using tube machines. The tube machines create the tubes and caps for these packaging products. Packaging industries rely on tube machines to produce functional and convenient packaging for businesses.

- Textile and Pipe Industries: In textile industries, tube machines produce textile tubes used for rolling up fabrics. These textile tubes help to organize and transport textiles efficiently. Pipe Industries, on the other hand, use tube machines to manufacture pipes for various fluid transportation applications. The machines create different types of pipes, including those manufactured from PVC, PE, and PPR, which are used in plumbing and irrigation systems.

- Medical Device Industries: Tube machines are also used in the medical device industry to manufacture medical tubes. Medical tubes such as catheters and intravenous (IV) tubes are produced using tube machines. The machines allow for precise and sterile production of these vital medical devices.

- Automotive and Construction Industries: These industries also benefit from tube machines, as they manufacture structural tubes and automotive tubes. Tube machines create tubes used in construction (such as those donning the role of support beams) and automotive tubes used in vehicles (such as exhaust tubes and coolant pipes). With their efficiency, tube machines fulfill the tube needs of automotive and construction industries.

- Customization and Prototype Services: Some businesses opt for custom tube machining services. This is as they have specific requirements that need to be met. In this case, service providers will use their tube machines to create custom tubes according to the business's unique specifications. Additionally, some service providers offer prototype production, allowing businesses to test and evaluate prototype tubes before full-scale production.

How to choose tube machines

When purchasing a tube-making machine, buyers should consider the following features and factors:

- Quality: Buyers should ensure that the tubes producing machines they are purchasing are of great and superior quality. They can do this by inspecting the machine's build materials and construction. They can also check relevant certifications, such as ISO certifications required for tube machines. A tube machine with solid build materials will ensure durability and withstand the rigors of constant use.

- Capacity: This refers to the amount or number of tubes the tubes-making machine can produce within a specified period, usually an hour. It is essential to choose a machine with the capacity to meet or align with the business's production requirements.

- Flexibility: Amongst the things a buyer should consider when purchasing tube machines is the machine's flexibility. Business owners typically produce different types of tubes, such as shaped, round, and oval tubes. As a result, it is important to choose a tube-making machine that can effortlessly handle various tube shapes and sizes. Also, the machine should be able to change quickly and easily to accommodate different materials, designs, and specifications.

- Automation: This refers to how automated the operation of the tube machines is. When purchasing a tube-making machine, buyers should consider the level of automation the machine offers. A machine with a high level of automation will offer increased productivity, streamlined operations, reduced labor costs, and improved efficiency.

Q&A

Q1: What are some new features found in modern tube machines?

A1: Modern tube machines come with new features like programmable logic controllers (PLCs), touch-screen interfaces, and automated feeding systems.

Q2: Which industries use tube machines the most?

A2: The automotive, construction, packaging, and aerospace industries heavily utilize tube machines.

Q3: What are some trends affecting tube machines in today's market?

A3: Trends like automation, customization, and eco-friendly production are impacting tube machines.

Q4: What's the future growth of tube machine markets?

A4: The tube machine market is expected to grow steadily due to the demand for efficient production in various industries.