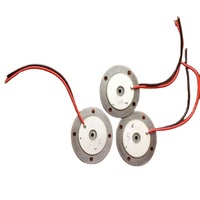

ultrasonic humidifier transducer

ultrasonic humidifier transducer

ultrasonic humidifier transducer

ultrasonic humidifier transducer

ultrasonic humidifier transducer

ultrasonic humidifier transducer

ultrasonic humidifier transducer

ultrasonic humidifier transducer

ultrasonic humidifier transducer

ultrasonic humidifier transducer

ultrasonic humidifier transducer

ultrasonic humidifier transducer

ultrasonic humidifier transducer

ultrasonic humidifier transducer

ultrasonic humidifier transducer

ultrasonic humidifier transducer

ultrasonic humidifier transducer

ultrasonic humidifier transducer

ultrasonic humidifier transducer

ultrasonic humidifier transducer

ultrasonic humidifier transducer

Types of Ultrasonic Humidifier Transducer

-

Piezoelectric Ceramic Transducers

Ultrasonic humidifier transducers utilize piezoelectric ceramic components to produce ultrasonic waves. When a piezoelectric ceramic element is supplied with an electric current, it vibrates and generates high-frequency sound waves, usually above 1 MHz.

These sound waves are then transmitted into the water within the humidifier. As the waves pass through the water, they create a fine mist of tiny water droplets. The size of these droplets is typically around 1 to 5 microns. This droplet size is ideal for being easily absorbed into the air without causing water accumulation.

-

Ultrasonic Transducer Arrays

Some more advanced humidifiers use transducer arrays instead of a single transducer. An array consists of multiple ultrasonic transmitters placed side by side. By controlling the activation of each transducer in the array, the emitted mist can be fine-tuned in quantity and direction.

A transducer array is an important transducer component that produces ultrasonic waves for devices like humidifiers. These arrays enhance mist generation by improving uniformity and enabling better control over mist output.

-

Ultrasonic Atomizers

Suppliers of large-scale industrial humidification systems commonly use ultrasonic atomizers as transducers. These ultrasonic ceramic humidifier transducers work by creating ultra-fine water particles through high-frequency vibrations.

Ultrasonic humidifier atomizers are powerful, producing high humidity levels. They are ideal for large spaces like warehouses, greenhouses, or industrial facilities.

-

Dry-Fire Protection

Many ultrasonic transducers now feature dry-fire protection. This function automatically stops the ultrasonic humidifier transducer from operating if the water level becomes too low.

This prevents the transducer from running without water, which could damage the ceramic components or lead to excess heat generation. Dry-fire protection helps prolong the transducer's life and ensures it only operates safely when there is enough water.

Durability and Materials for Ultrasonic Humidifier Transducer

-

Ceramic

Ceramic is a widely used material for ultrasonic transducers due to its excellent durability and ability to withstand prolonged exposure to water. 90% of transducers for home humidifiers are made from a piezoelectric ceramic disc. The piezoelectric effect allows the ceramic to convert electrical energy into ultrasonic vibrations. This is key for generating the mist in humidifiers.

Ceramic's toughness ensures that the transducer can operate reliably over many years without degradation. In more powerful industrial models, ceramic atomizers are made from robust full- or part-ceramics. These materials offer additional strength and heat resistance.

-

Titanium

Titanium is one of the most durable metals and is used in ultrasonic transducers where extreme conditions demand ultra-strength. It is often found in high-end transducers, such as those used in large industrial humidification systems or sensitive labs.

Titanium's incredible durability can withstand long-term continuous water contact, intense humidity, and chemical exposure without corroding. Its ability to maintain excellent mist generation performance over time makes titanium a go-to choice for humidifier transducer manufacturing.

-

Stainless Steel

Stainless steel is a great balance of durability and affordability, making it ideal for transducers in commercial settings. Unlike brass, which is more electroconductive but less water-resistant, stainless steel doesn't corrode in humid environments.

Brass is often used in cheap models, but stainless steel's corrosion resistance and electroconductivity make it suited to higher-quality humidifiers. Both materials are electrical conductors, allowing the transducer to convert energy for mist generation.

-

Brass

Brass transducers are economically found in many household humidifiers. While less durable than stainless steel, brass is much more electrically conductive, allowing even lower-power models to generate ultrasonic mist effectively.

However, continuous water contact over time causes corrosion. For budget-friendly humidifiers, brass transducers perform adequately. But for long-term reliability, more corrosion-resistant options like stainless steel or titanium are preferable.

Commercial uses of ultrasonic humidifier transducer

-

Industrial Humidification Systems

Transducers are used in industrial humidification controls, like CUMM, which regulate the mist output in large-scale humidification systems for factories, warehouses, and greenhouses. This helps maintain desired humidity levels for worker comfort, product preservation, and crop health.

-

Laboratories

Transducers power humidifiers in research and development labs where precise humidity control protects sensitive materials and equipment and ensures consistency in experiments. Accurate humidity levels are critical for reliable scientific testing and product development outcomes.

-

Data Centers

Transducers in humidifier machines maintain optimal humidity in data centers to prevent static electricity build-up that could damage servers and other computer equipment. Keeping air moisture levels stable protects vital technology infrastructure in these dynamic commercial environments.

-

Pharmaceutical Manufacturing

Pharmaceutical factories use active humidification systems where ultrasonic transducer humidifiers safeguard drugs, vaccines, and medical supplies by controlling humidity to preserve stability and prolong shelf life. This quality assurance is critical in healthcare environments.

-

Textile Factories

Textile plants rely on transducers in air humidifiers to keep fibers damp, making them easier to work with in spinning, weaving, and sewing processes. Maintaining the right humidity levels is key to producing quality fabrics and garments without drying or damaging materials.

-

Greenhouses

Ultrasonic transducer atomizers boost humidity in agricultural greenhouses, optimizing conditions for plant growth. This supports farmers' target humidity levels for robust seedlings, strong crops, and higher agricultural yields. Healthy plants result from transducer-powered indoor climate control.

-

Agricultural Settings

Farmers rely on transducers to hydrate crops and boost greenhouse humidity, accelerating growth and upping their harvest game. Managing moisture with these techs gives plants the perfect environment all year for strength and health, ensuring green thumbs get bumper crops.

-

Printing Industry

Printing facilities depend on transducers in their humidifiers to keep paper at the right moisture level. This prevents warping and guarantees clear, crisp prints. By balancing humidity, they ensure top-quality prints without paper issues that slow down business.

How to Choose Ultrasonic Humidifier Transducer

-

Market Needs

Buyers should first assess the demands of their target consumers. For example, if targeting larger spaces, choose coils that produce greater outputs. It's also important to gauge the competition -research rival brands and models so buyers can offer unique transducer features that set their humidifiers apart.

-

Space Requirements

Customers have different needs based on the size of their areas. Buyers should look for transducers that let humidifiers regulate small, medium, or large rooms up to oversized spaces like offices. Finding the right transducer ensures humidifiers achieve optimum performance in spaces of all sizes.

-

Durability

Transducers containing strong, water-resistant materials like titanium or stainless steel are ideal. These tough components ensure humidifiers last through heavy use without breakdowns. Customers will favor durable models that stand the test of time and deliver reliable mist generation.

-

How It Affects Buyers

Customers will choose a model based on how efficiently it delivers the desired humidity. Buyers ought to compare transducer mist outputs to what is needed for each hyperbaric humidifier role. Transducers that provide optimal output will fulfill customer needs effectively.

-

Operating Costs

Transducers also impact energy usage and maintenance costs. Buyers should look for efficient models with low power consumption and easy upkeep. This lowers long-term expenses and makes humidifiers more economical for customers to operate consistently.

-

Technical Specs

Buyers should compare transducers based on key qualities, like the frequencies they use and mist sizes. This determines how well the humidifiers perform distinct tasks. Customers will appreciate models powered by advanced transducers that provide superior mist quality and air moisture enhancement.

Q&A

Q1. What do ultrasonic humidifier transducers do?

A1. In humidifier, the transducers use ultrasound waves to break water into a fine mist for easy inhalation. They generate tiny droplets that increase room air moisture for better breathing.

Q2. Why does an ultrasonic humidifier need a transducer?

A2. The transducer is an essential part of an ultrasonic humidifier. It nebulizes or atomizes the water and converts it into tiny mist particles for the room air humidification.

Q3. How should buyers maintain transducer humidifiers?

A3. Buyers should regularly clean ultrasonic humidifier transducers and replace water per instructions. This prevents germs and mineral buildup from dirty water that can harm health over time.

Q4. What happens if the ultrasonic transducer is broken?

A4. If the transducer breaks, water will not be nebulized properly. This will cause problems with humidity levels, such as low humidity or dry air and issues with germs in stagnant water.

Q5. How long do transducers last in humidifiers?

A5. Strong, durable transducers like titanium can last several years. Regular cleaning helps the transducer last longer by preventing mineral buildup and other blockages.